Thin wall injection mold is one of the project of SINO MOULD.Combined with Dakumar machine, we can offer you the turnkey line project forthe thin wall high speed injection molding solutions with the labeling system.The robot is side in labeling system with servo system made in Italy.

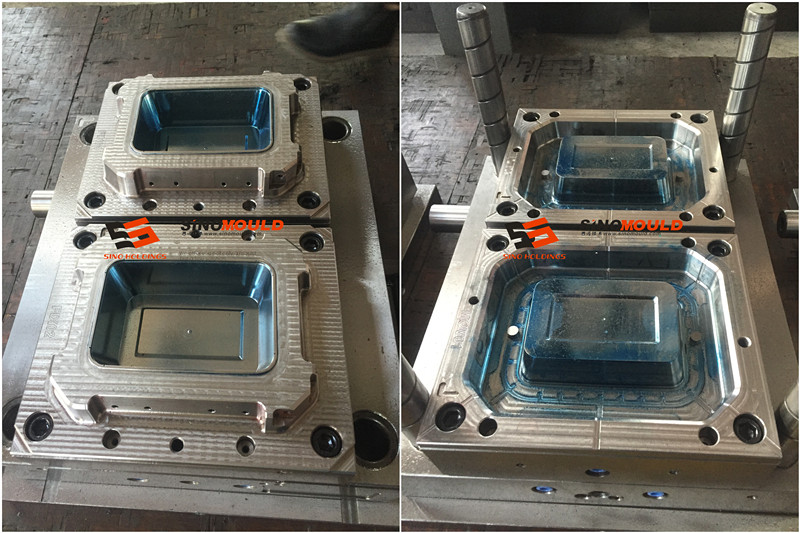

Product information item:PP cup with IML capacity

Max: 250ml

Dimension up: 139x98mm

Dimension bottom: 90x65mm

Height: 45mm

Weight: 11.4g

Plastic material: PP foodgrade raw material

Mold size: 416x256x275 mm

Cycle time: 8s

Product material: PP

Cavity: 2

Gate way: valve gate, pingate

Machine: DKM188

Mold material: 2344,2738, 2311(withCuBe)

Ejection type: stripper

We have the richexperiences in mold and machine, including design, processing, we have a hybridhigh-speed machine. As for robot aspects, we have the price concessions, we areItalian partners, we have ex-factory price, it’s absolutely lower than thecustomer to inquiry to their own low. The robot performance is stable and highefficiency.

Please feel free to contact us when you need any thin wall injectionmolds or when you need high speed thin wall injection mold solutions. We can provide you with a fine solution.

Posted by Miss Nancy

Skype:sinomould-01

Email:export@sinomould.com

WhatsApp:+8613758679372

SINO has very mature experience with multi cavity thin wall IML container molds.

The4 cavity of 1 literthin wall containermold we can make now is only 0.4mm thickness, cycle time around 5-6seconds.Annually, we make over 300 setsthin wall container molds.

Thetechnology of the thinwall injection mold is important during the moldingprocess, we choice the correct steel to ensure the dimension(usually it is S136from ASSAB)based the problem to adopt right measurement.

1.Thinwallhigh speed injection mold supplier: SINO-MOULD

2.Hotterrunner suppler: Anole Hot Runner

3.Robotsuppler: DKM robot system combine with Italy technology.

MainChinese thinwall injection mold technology problem and solution:

1.Airsystem design: Trapped gas, burns and short shot due to the thinwall forming oflarge area. During design, we need to make mold flow analyse.

2.Controlof the deformation: hard ejection of the forming because of the complex of themold structure. When design ejector ,we need to pay more attention about thispoint and try to avoid the problem.

3.Guaranteeof the mold hardness: assure the mold overall compression based on thestructure and material used. As a famous supplier, we usually use S136 fromASSAB.

4.Researchof the thinwall forming technical: thinwall products' flow channel is narrowerthan the traditional's ,easier cooling during the forming process, this is thekey point. We usual optimization molding process parameters,make reasonablemolding process to ensure the technology specification

Snow

export@sinomould.com

Sino Mould is a professional plastic mould suppliers, Sinostool mould is very popular in the market. At the same time, Sino is one of thesuppliers' with high-quality, high precision molds. We are always facus onproviding technology to solve problemsfor customers wthin product quality control and service. Compared with other suppliers, Sino is outstanding.

In the pre production of plastic stool mold, we will providethe most suitable solutions and make recommendations for the customer , such asplastic stool size, steel material and so on . we will give some reasonablesuggestions, such as: P20,718 steel which can be produced, with conventionalplastic stool mold , it suggested to use P20 steel material. The good steel materialis established in the customer demand for long life of the mold, high qualityrequirements of the products . And the all steel we used is provided by Chinaand famous foreign steel manufacturers, as well as heat treatment and HRC:

we commissioned a professional company with heat treatment,heating on different components and requirements of steel hardness and used fora long time, the core hardness and a plastic stool mold cavity can reachHRC32-36 after pretreatment, and all components are composed of CNC lathemachining, the assembly of plastic stools mould are all the experienced moldworkers and complete by handmade. We own reasonable heat treatment process andprecision machining. And the production cycle is around 20 - 32S.

If you are looking for a plastic stool mold manufacturer,please contact us, Sino Stool mould will be your best choice. Sino will provideyou the high quality and the best service.

Postedby: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype:Sino mould-Rose

SINO HOLDINGS GROUP specialized in different size, different shape, different volume paint bucket moulding line. We can offer you A to Z service for complete paint pail production line.

The advantage of paint buckets moulding line:

1) The mould will be coordinate with machine better. Because SINO GROUP makes own paint pail mould according to own injection machine. Mould and machine will be tested together before shipment.

2) Buy production line can save your investment. For mould and machine order together, we offer big discounts support to customers.

3) The before sales service and after sales service will be easier and save your energy & time. You don’t have to communicating with different companies for only small questions. Every company says they have service, but not every one can help you solve problem in time. They may making excuses and push the responsibility to others. Now SINO GROUP can offer you guarantee for both mould and injection machine. Our engineer can go to your workshop and training your engineers. Or you send people to study how to operating mould machine machine in our company.

For any question about paint bucket injection moulding line, i will be your Consultant and help you solve problems. Welcome to contact SKYPE: sino-mould02

SINO HOLDIGN GROUP isone of the Chinese famous foldable crate supplier. We can provide customerwith variety of high quality, high performance foldable crate.

Carton crate is used inthe early 90, the nature and value can be said a one-off. Ad a user, it nothuman and material resources. It’s not convenient, people need to procurementstaff and pack assemblers. Compared the convenient, plastic crates are increasedthe frequency of repeated use. Save resources is the most basic factor of uswhy choose the plastic crates.

However, why more peoplelike to choose the foldable crates than plastic crates?

Foldable crate has theadvantages of saving logistics cost and storage cost compared with ordinaryplastic crated. The height of SHG folding crate is only 1/5 of the originalheight, and it’s can be placed on the tray. In this way, you can save logisticscosts and labor costs. Foldable crate has been a large number of applicationsin foreign countries, the recent rise in the past 2 years, and later willreplace the ordinary crate.

With such a turnoverbox system, it has contributed to the reduction of circulating costs such aspacking, packing, handling, handling and storage. It has created a highefficiency and high quality turnover box system. Folding turnover box has beenwidely used in foreign countries.

If you are interested in our plastic foldable crate, please contact us. Asfor we are the best Chinese Foldable Crate Supplier.

Posted by Miss Nancy

Skype:sinomould-01

email:export@sinomould.com

Whatsapp:+8613758679372

Household garbage bin mold, one of our daily usualplastic injection molds, have a big market in commodity trade. It has manycapacity, 1L,5L,15L,20 L and so on. The usual material for it is PP. While theindustrial used dustbin use HDPE for production.

SINO ,as one of China famous plastic injectionmolding expert,have develop manyhousehold garbage production line for clients around the world.

During the past 27 years, we .SINO HOLDINGS hasoffered and delivered a lot of household garbage bin production line forclients all over the world. We help customer built their factory from zero intheir field, arrange production line shipping for them and train their engineerone by one step.

Further more, we help clients to open their marketand get profit for both our side.

Nowadays, we have develop more than 20 agents allover the world, such as Greece, Mexico, Jordan, ect. These agents can offerconvenient and efficient service for our service, especially for after-saleservice. And they also have some spare parts in stock, can change for clientswhen meet spare parts broken problem.

Any interested about our garbage bin productionline, please feel free to contact me. Welcome to our city for company visitingand further discussion.

Snow

export@sinomould.com

Sino Holdings Group started out as plastic injection molds manufacturer. Annually, we provides about 90 sets chair molds with vary types, plastic school arm chair molds, PC chair molds, ghost chair molds, stool molds, gas assistant chair molds, leisure chair molds, beach molds ect.

For plastic arm chair molds, main quality points are parting line, air venting, fast cycle time, strength, and delivery time. With more than decade’s experience, Sino could supply good quality chair molds within 65 days. Like school chair strength point, through Moldflow analysis software, we design suitable strengthen ribs on chair seat back and legs. And for chair material, expect PP raw material, we mixed a certain percent calcium carton to reach reasonable weight with best chair strength. After molding, we will test school arm chair strength and stacking with 24 hours.

In addition, we offer you turnkey solution for new chair production line, with all devices of chair production machines, necessary auxiliaries, sending our technical people to your site for equipment installation and adjustment, staff training and so on.Welcome you visit and enquiry to Sino Holdings Group’s two factories located in Huangyan, Taizhou city.

Posted by Ms.Helen Chen

Skype:sino.group10

Whatsapp: 008615858625783 (wechat)

Email: export@sinomould.comexport@sinomould.com

With the pace of life to speed up, now more and more people like convenience in daily life. So, the disposable plastic cutlery is becoming more and more popular in our life,it has much demand in the market, at the same time the plastic spoon also has much demand. SINO Mould is a professionaldisposable plastic spoon mouldsupplier. We have gathered rich experience in plastic spoon molding, and we can provide any type of spoon mould that you want .

We offer plastic spoon mould such as 12 cavity, 24cavity, 32 cavity, 64cavity for plastic spoon mould, it can run with cycle time of 5seconds.

Below is the plastic spoon mold specification,

1. Product:24 cavity plastic spoon mould

2. Product material:PS/PP

3. Applicable scope: Military spoon、Aviation spoon、Daily spoon

4. Size: Ordinary spoon:165mm,2.5g-3.5g

Coffee spoon:120-135mm,1.5g-2g

5.The steel of mold: S136.H13.2344.2316

6.Cycle time: Ordinary spoon:165mm,2.5g-3.5g

Coffee spoon: 120-135mm, 1.5g-2g

7.Runner : cold runner

8.Parting line: Tend to toward the back of the spoon (won’t be hurt the mouth)

9.Suitable injection machine: DKM268 servo motor(24 cavity and 32 cavity)

Our company also can produce various different kind of disposable plastic cutlery. Such as plastic PS cups mould, plastic fork and knife mo uld, thin-wall food container mould, etc.

The products are confirmed by the customer, if the sample is up to standard, the mold shipped. If there are any technical problems, you can contact with me, I will be the first time for you to resolve.

Welcome your enquiry for all types disposable plastic spoon mould.

Miss. Miya

E-mail: export@sinomould.com

whatsapp: 008615712676816

Skype: sino mould –Miya

SINO MOULD is the most famous PET Preform mould maker in china and whole world. With more than 15 year of experience in manufacturing PET mould we have succeed in manufacturing 144 cavity pet preform mould .SINO has highly experienced design and technical team for PET preform mould manufacture. With the continuous development in manufacturing advanced , fast,quality mould we are able to erect big business empire in the mould market throughout the world.

Proper selection of steel, precise processing, tolerance, German heating system are the features making mould more powerful to compete in the world market. We not only manufacture mould butprovide fine and cost effective solution to the customers. We are specialized in providing solution for whole bottle production line. We can also build the perfect mould for your project as per customers requirement like preform design, neck size, extra cores and cavities. We are truly specialized in quality and cost effective PET Preform mould manufacturer.

Some dominant features includes:

Cavities up to 144

Interchangeable core and cavities , makes customers easy to produce different weight and design preform

Extra core and cavities to keep as spare parts

Advanced hot runner with German heating element

Stavax S420 steel for cores and cavity tempered with 55+/-2

Advantages of our Turnkey Solution:

Easy handling of your purchase

Quick delivery of all goods together

Avoid arguing betweeen different suppliers

Fast response for your doubt

Strong design ability and uniformity

Profit in very less time

Prompt after sales service

For any further information don’t hesitate to connect.

Rahul shah

export@sinomould.com

whatsapp : 008613989381153

We, Sino Automotive Mould Co., LTD is the leading injection mould supplier for automotive industry in China, specialized in automotive moulds, like grilles, auto light, bumper, shock absorber, fan tray and so on. We havedeveloped international market for OEM and after-sales market for brand suchas: HONDA, NISSAN, TOYOTA, CITROEN, etc.

The plastic injection auto part moulds provided by SINO are high appreciated by the customers from all over the world. We adopt project management and quality control system to ensure all the moulds quality and delivery time. Our quality control Dept. will check every step of mould, from steel quality inspection to mould quality approval before shipment. Customer can getall tooling and inspection reports from us. At the same time, our project Dept.will make progress report every 10 days to let the customer learn mould tooling situation and avoid delivery delay. They will also collating files for the whole project, like photo and vedio for mould test, record for mould test specification, updated 2D&3D drawings and so on.

Pls kindly remember that Sino is not only Chinese famous plastic injection auto part mould factory, but also plastic injection auto part production line supplier, which means we can help you set up your own plastic injection autopart molding factory.

Post by Miss Mandy

Email: export@sinomould.com

Whatsapp: +8615757610702

Sino Mould company is a professional mould manufacturer in China for plastic pallet mould making, we supply high quality pallet mould for different types, such as nine-leg pallet mould, grid-window pallet mould, double-grid pallet mould and so on. We could offer turnkey solution for the pallet molding line setup, include all the injection molding devices and staff training.

For the grid-window pallet mould, we supply for the size like 1000*1200*150mm, 1100*1100*135mm, 1300*1100*160mm and so on. For this kind of pallet mould, consider the pallet design, it required to use hydraulic cylinder to drive the sliders moving during demolding. We use P20, 718H and other good steel material for the mould core, cavity and sliders. The mould size is around 1800*1500*1000mm, with the injection molding machine size DKM2600ton.

Sino mould supplied pallet moulds to different market all around the world, like South Africa, Brazil, Iran, Spain, Poland and so on. We could help customer setup new pallet production line with all the molding equipment required, and arrange our service engineer to customer workshop to assemble the machines, training staff and so on. It is also welcome if the new customer could come and learn in Sino Plant. If you have new plan to setup new plastic pallet production line, welcome to conatct us, we could offer you a fine solution. Thanks.

Post by Miss Celina

Email: export@sinomould.com

skype: sinomould.dakumar7

whatsapp: 008615257606120

Sino holdings group company we are going to be best PET bottle injection molding line equipment manufacturer in China. Pet bottle is highcapacity production, usually around one million monthly, PET bottles injectionmolding equipment including injection mould, injection machine, auto loader,chiller, dryer, Air compressor etc.

Base on our good experience in pet preform mould from branch company-Sino Mould co and injection molding machine co-Dakumar machinery, We had setup production line for many customers, which is from Turkey, Thailand, UAE,Brazil and so on..

Considering the pet bottles making step are difficult, customershould know Pet bottle molding very well then they can choose suitable solutionby their self. But most customers they don't want speed more time for chooseequipment or they do not how to choose good solution. In addition, Customersare more concerned about the after-sales service, if one company can do allservices and can know all equipment running it will be more easy and convenientfor customer.

So, One professional PET bottle injection molding equipmentmanufacturer will considering:1) Per-sales:Customizedsuitable solution for customer. 2) Good quality controlling by machining ortest report, Simulation production above 5-8hours to confirm production line stability.3) after-sales service on time, supply engineer to customer factory forinstallation, adjusting or training.

Welcome you down visit to our company: Sino Holdings Group, welcome you!

Welcome you down visit to our company: Sino Holdings Group, welcome you!

Email: export@sinomould.com

What’s up: 0086 15858625783