Sino Mould Co.,Ltd was founded in the years of 2000,we have been engaged in injection and mold designand manufacturer for more than twenty years. We are the professional injectionmold manufacturer and customized in plastic products manufacturer in insoutheast of China. Our company has strong technical team and advanced manufacturingequipment to make expansion screwmold. There are more than 800 employees in ourcompany, the majority of whom is professional designers and experiencedtechnicians.

Expansion bolt is the roleof objects in the wall board was rooted. Twist the middle of the nut, so thatthe middle of the outer wall of the screw to distract the wall, squeeze thewall in advance to fight, the use of friction so that it is not easy to falloff, so as to achieve the purpose of rooting. Expansion bolts, is to make thewind pipe support, hanging, bracket fixed to the wall, floor, the column used aspecial thread connector.

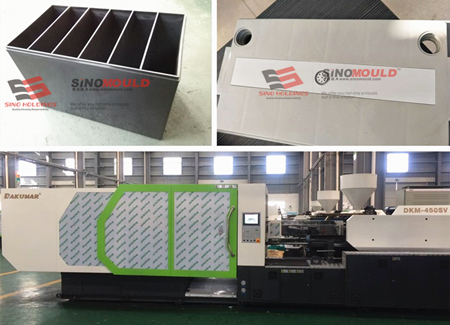

Mold information:

Product material: PA66

Shrinkage: 1.10%

Cavities: 24

Cycle time: 15S

Mold size: 400*400*420

Runner: cold runner

Mold life: 10K

Mold material: S136

Machine: DKM130T

We are using Solid work,UG and Auto CAD software to design drawing for our customers. With advancedmolding technology, wire cutting machine, and CNC manufacturing centers, we candevelop high quality molds and plastic injection products.

Our company would provideour customer a good molding solution. If you have any needs on china expansion mold, please feel free to contact Nancy.

Skype: sinomould-01

E-mail: export@sinomould.com

WhatsApp: +8613758679372

SINO HOLDING GROUP has rich experience in making plastic beer crate mold. We are a professional mold maker withalmost 20 years. We can provide various kinds of mold or customize according toclients requirements. We can quote the price based on drawing or samples withyou provide.

We offer the beer crate mold bottle crate design and various beer cratespeed injection molding solutions and with competitive price. The cavity numberis according to customer’s requirement, and we will use hot runner in ANOLEbrand. The mold material is P20.

We use design software are UG, CAD, CAM, ect. Because plastic crate molddesign also is very important, it is better to use a mechanical system into themilk crate mold ejection, in this way, you can make the ejection action whenthe mold opening. Of course, maybe your machine can work with the 2 hydraulicacting in the same time, then you can do the ejection when the mold opening.For all kinds of mold , the high speed running is based on the mold ismachining, the movements parts with accurate guided… otherwise, there is nonpossibility for a mold high speed performance.

If you have the demand in our plasticbeer crate mold, pls feel free to contact Miss Nancy.

Skype:sinomould-01

E-mail:export@sinomould.com

WhatsApp:+8613758679372

Sino Mould company specialize in the plastic injection battery box mould manufacture.Each year exported more than 20sets battery box mould.As is know to all,Battery box most adopt the PP material, Considering the the rib thickness andwall depth,Hot runner system is demanded to make the best forming.DIN 1.2316 and 718H is the most choice for the moulds core and cavity material.There are many specification for the auto battery box,also there has the international standard,some large scale enterprise owns their specific standards.Sino mould accept tailor made battery box mould.

Regard the hotrunner layout,Normally is the same level.Usually one grid controlled by one injection nozzle forming.Some customer request use one nozzle control two grid.For this we need take consider that the rib between the two grid,would appear transformation.Usually we don’t recommend customer make moulds like this.Sino mould consider more about the battery box mould cooling and forming cycle time.For best automatic injection,we would consider make the best ejection draft during design period. And the rib thickness request thinner than the wall,otherwise there would appear shrinkage mark on the battery box surface.The size of the box control is the most important for the moulds production main key.Before make design,better request customer provide the 2d design which marked size with tolerance. And confirm with customer with all thedetail final size checking request.

Sino mould company warmly welcome world wide oversea market customer visit us and have detail consultation for the tailor made battery box mould.Please feel free to check with us about the battery moulds detail.Sino mould devote to battery box mould more than 20 years,owns rich experience. Just email us. Mail:export@sinomould.com Whatsapp:008615067608197

SINO MOULD has a long history and matureexperience to produce automotive part moulds. We makes auto lamp moulds,automotive bumper moulds, door trim mould, etc.

Regarding to automotive moulds, the steeland hot runner quality is very important. SINO MOULD will do mold develop feasibilityanalysis before the mould design. Also mold flow analysis is necessary. It willhelp us learn the problem may happen to the mould development and avoid ithappen in the beginning. Mould is a very precision tool, once the design wrong,then the rest works are wrong. So the quality control in automotive part designis very important. For OEM auto part mould, it will have high requirement tothe mould spare parts brand, such as guide pin, hydraulic cylinder, wear-plate,eject pin standard etc. In order to let the auto parts have perfect surface,auto part moulds always adopt valve gate hot runner system, it also have bettermaterial flow. SINO MOULD have the most advanced precision tooling machine,professional mould making team, and quality control system for auto part moulds.

If you have automotivepart mould want to develop, SINO sales engineer Summer is here waiting for you. Inquiry email: export@sinomould.com Skype: sino-mould02.

Sino Mould is a professional mould maker for plastic battery box mould in China, we supply different types battery box mould, such as UPS battery box mould, automotive battery box mould, electrical bicycle battery box mould and so on. We could make the battery box mould with one cavity and two cavity according to the production capacity requirement.

For the battery box mould, usually it is seperate for three housing, or 6housing, so the rib in the middle area is very deep, in order to make sure the mould quality, the mould core side must with high hardness steel material, and required high precision tooling. usually we suggest use H13 or better steel material for the core side, for the cavity side, we could use 718H or other suitable steel material. The battery box mould is with hot runner system for 6-7tips injection gate.

We have experience for the battery box lid with 2mm depth undercut rib, but the diameter is only 28mm for the hole, we use collapsible core for the mould structure, so it could run stably for the demolding.

Sino Mould could supply whole production line for the plastic battery box mass production, include all the equipment for plastic battery box mould, box injection molding machine and other necessary additional machines. Welcome to contact us for more information. We are OK for arrange engineers to visit your workshop to help setup the machines and support staff training. Thanks.

Post by Miss Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

Whatsapp: 008615257606120

Sino Mould company is a famous plasticcrates mold manufacturer which has 24 years experience. Especially in fruitsand vegetables, bread box , beer box, coke box, folding turnover box mold.

InChina mold manufacturers, most of them want to produce the plastic crates moldof high quality and Sino provide customers 4 cavity and 2 cavity crates mold. Weprovide United customers thin-walled box, we usually export 100 crates mould tothe foreign market every year.

ToSino, plastic crates mold is one of the most common and simple mould, we notonly have our own mould production standards, but also has its own design teamand professional R & D team, it is the first test mode of success.

Such as: the use of hot runner structure, we also have their ownunique suggestions, such as cavity of crates mold , which has the advantages ofsimple structure, while the 2 cavity and 4 cavity crates mold, we will usedouble hot runner, some crates molds, can also use recycled materials, we havethe filter design system to protect box molding.

The crates mould which produced by Sino mold, we are mainly based oncustomer demand, to ensure the molding cycle speed, hydraulic pressure will berelatively stable.

At the same time in order to shorten ourcycle time of plastic turnover box mold, we also specially made standard form,so that we can guarantee the quality of the mold, can also save the moldproduction cycle.We also prepared some necessary mold components at the sametime in accessories, because there are a lot of plastic turnover this box moldorders every month.

If you are looking for a plastic crates mold manufacturer, please donot hesitate to contact me

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Sinomoulhas richexperience in thin wall fast foodcontainer mold manufacturing. Sino can help customers build all kinds ofplastic injection molding factory, especially fast food box and thin wallmolding of thin-walled box. we canproduce thin-walled snack box mould with high quality according to theproduct design and mold design.

Wealso offer suitableinjection molding machine, robot andnecessary the auxiliary equipment to help our customers achieve excellence inproduction capacity, at the cost of investment, Sino mould company hasadvantages in making thin-walled food container mould production line:

The first factor: thin-walled food container mould is the mostimportant to produce products of thickness, the thinner the better, because itmay increase the cost of the material and the production cycle, so we experiencedengineering team analysis, need to be cut to 0.35 mm in thickness, may be verydifficult, but Sino can offer you the professional technical team.

Second, short cycle time, our designers will according to customerrequirements for product analysis, and try to find out the best water to die,more important is the characteristics of the technical team to develop highspeed injection molding thin-wall snack box is our 4 cavity thickness is0.35mm, 0.5L, 3.5S cycle.

Third, we can provide IML according to customer requirements, moreattractive IML products, more profound impression on customers. So, more andmore customers want to do IML mold frame, in order to help customers save laborcost, improve production efficiency, we can also provide the robot and theinjection molding machine is suitable for every mold.

Fourth, when the thin-wall snack box moldand equipment to meet customer requirements can be produced, we will assignexperienced engineers to the customer site to teach their staff, they will helpmould and equipment operation, to ensure their smooth operation and stableproduction.

If you are looking for Thin wall fast food container mold supplier, please contact us, wecan not only help you produce Thin wallfast food container mold but can also provide you relevant productionsolutions.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Plastic water cap mold is one of the common plastic cap mold. This kinds of cap mold made and avoid water leakage. It is the special requirement for water cap molding.

SINO MOULD., ltd.Co, world well known plastic injection mold making supplier, also very famous in plastic injection molding area. We have strong design and manufacture capacity .We are feature in plastic cap mold unscrewing ejection system, PET preform molding valve gate system and cooling system, extrusion blowing mold auto deflashing system and so on.  Based on our past 20 years’ experience in plastic injection molding area, we have an ability to offer you a total plastic cap molding turnkey solution, including plastic cap mold, plastic injection molding machine and any other assessories.

Based on our past 20 years’ experience in plastic injection molding area, we have an ability to offer you a total plastic cap molding turnkey solution, including plastic cap mold, plastic injection molding machine and any other assessories.

Because we have brother company—Dakumar Machinery, famous in plastic injection molding machine area and also have many agent can offer clients convenient and fast service for clients all over the world.

In a total ,if you want to develop a plastic injection molding factory, please feel free to contact us. We will help you start from zero and then become the leader among your competitors. High quality mold and prompt aftersale service. Sino is eager to grow with you shoulder by shoulder.

Snow

export@sinomould.com

Sino Mould Limited companyhas accumulated rich experience, help build all kinds of plastic productsproduction line, customers such as: industrialtrash production line, IML injection molding line, medical plastic moldingline, household products molding line, industrial dust production line, thelarge tray production line, auto plastic parts production parts, PVC pipejoints connecting line etc..

Let us use production line with industrial trashas an example to share Masino mold company is how to help customers quicklybuild plastic molding production line.

Pre sale:

Pre sale:

1, when a customer inquiry, we will provide oneof the service sales engineer, our sales engineers will help customers toconduct a market survey, find out the industrial trash which type is currentlyon the market relatively popular, and the monthly production demand is much.

2, we will calculate the daily productioncapacity and the number of equipment based on the monthly demand, so thatcustomers can more clearly understand the details of the list of equipment andcosts.

3, we will help customers to help the factorylayout and planning, as well as the design of the factory, to help customerssave time and cost, get the maximum use of space.

After sale:

We can provide customers with 24 hours of onlineservice, if our equipment have problems, we will be the first time to providecustomers with free solutions. If the customer does not have the appropriatetechnical staff, we plan to provide quarterly or annual training services toour customers. We have many years of practical experience, and a wide range ofbusiness. In the past two years, the industrialtrash can production line has become more and more popular. If you want tobuild your own plastic molding plant and industrial waste bin production line,please contact me, we will be happy to share our experience with you.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Sino Mould have more than 15years for plastic air conditioner mold making, with our good rich experiences and high QC standard for central air conditioner molds ,hanging air conditioner molds etc…we are your good choice for central air conditioner molds manufacturers from china.

We had supplied different kinds airconditioner plastic molds to Saudi Arabia, Iran, Ukraine, Brazil ,Denmark andso on, mold quality considering humanized design, best cooling system, mouldmaterial DIN1.2738 or 718 material f suitable for polishing and longer mold life,moldflow analysis to choose proper position for injection molding, to avoidcentral air conditioner deformed or not flat.

Central air conditioner molds also needconsidering precision machining, to let the parts have good assembly, usuallywe use machining first step by common CNC, then 2nd step by high precisionCNC to controlling the mold insert in right dimension, and strict QC examinationfor each parts of molds.

We are good at make air conditioner mold exceptprecision machining, good mold assembly also we know well about air conditionermold injection molding process, to solve frequently problem during injection,to leach our customer in good study.

We welcome you down visit in our company toknow well about us for household appliances molds, if you are looking for good central air condtioner molds manufacturers please do not hesitate to contact us:

Email: export@sinomould.com

What’s up: 008615858625783

We have a ready gas assistance wicker chair mold and machines in ourfactory. All necessary equipment hasbeen included, which means when you get these products, you can start production without any delay.

We have posted our mould production video to the YouTube(https://www.youtube.com/watch?v=VLS0iveAf3U&t=1s), so that you can see it very clearly.

Gas assists rattan chair mould:

Chair weight: 3.8kg

Chair load weight: 5 times more than normal PP chair

Chair material: PP

Cycle time: 2 min

Machine model: DKM-1600

Machine tie bar distance: 1500*1500mm

Injection weight: 10776g

Clamping force: 16000KN

Now we have a special discount for this chair production line, you will get the DKM1600 machine with DKM1100 machine cost. In other words, the total project price will be reduced USD100,000 from our standard price.

So if you are the one who is in rattan chair production, and have plan to expand production ability, welcome contact me freely.

If you are the one who are interested in plastic chair production, Rattan chair is the most popular in recent years. Contact meto get the detailed quotation and equipment information. We will send engineer to your factory to help you build up you new factory.

We are not only offer a gas assistance wicker chair mold or machine, but also a fine solution, Turnkey project and factory building.

sales engineer: Candy

email: export@sinomould.com

whatsapp: 008615858685263

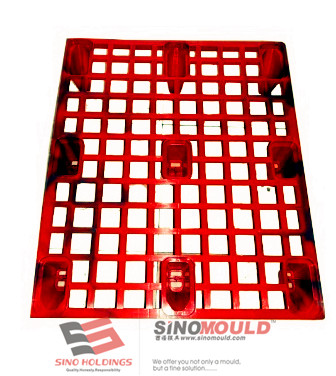

In recent years, China's plastic pallet mold manufacturing level has been greater progress. As a professional plastic pallet mold supplier in China, we can provide you good design and quality to meet your requirement, even pallet turnkey solution. We have rich experience in pallet mold,

Below is technical point to make molds:

1.Pallets has generally the standard size, such as the European standard

2.Because of big pallet size, cycle time and cooling time is longer.

3.Gate way need more hot runner

4.Mold with or without slider, the resistance of slider structure.

5.Plastic pallet and the impact of its performance, to withstand static load and dynamicload capacity

Let’s take a picture as an example, the pallet size is 1000*1200*150mm, 16kg, after our designer make drawing, the pallet mold size is 1600*1200*940mm, P20 cavity/core steel , H13 slide steel, injection gate is 13 tip hot runner, ejection way is ejectorpin .If you are high requirement for pallet, you can choose 718H cavity/core steel. At present the main production of plastic pallets material is PP, it suitable for high load, high life of the pallet. Machine size is DKM SV1650T,cycle time is 160s. Not only mold, but also machine we can provide.

Any needs, pls feel free to contact us.

Post by Vicky

Email:export@sinomould.com

Skype: sinogroupe-59