SHG isthe professional injection mould manufacturer and customized in Beer crate mould in china. Our company has strong technicalteam and advanced manufacturing equipment. Carton turnover box is the early1990s with a turnover of more than a box, its nature and value can be said tobe a one-off, the other as the user is concerned, the carton used once aprocurement, is very not human and material resources, in this link must be alot of staff, for example, procurement personnel, packaging and assembly personal,one by one can be shipped in sealed boxes. That compared to plastic turnoverbox is also very obvious Kai to a convenient and quick, increasing thefrequency of reuse. Saving manpower and material resources and is the mostbasic reason why the choice of plastic turnover box factors.

SHGfoldable crate is widely used in machinery, automobiles, home appliances, lightindustry, electronics and other industries, can be acid and alkali, oil,non-toxic and tasteless, can be used in full bloom food, clean convenience,convenient parts turnover, stacked neat and easy to manage.

It’sreasonable design, excellent quality, suitable for factory logistics in thetransport, distribution, storage, circulation processing and other sectors. Theturnover box can be used with a variety of logistics containers and stationequipment for various types of warehouses, production sites and otheroccasions, the logistics management have more and more attention to themajority of enterprises. The turnover of containers to help complete thegeneralization of logistics containers, production and circulation enterprisesare essential for modern logistics management products.

If youare interested in Beer crate mould, Pls feel freeto contact Nancy.

Skype:sinomould-01

E-mail: export@sinomould.com

WhatsApp:+8613758679372

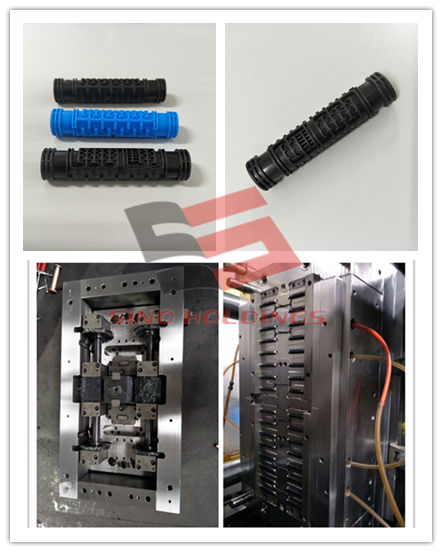

SINO Mould is a plastic water dripper mould manufacturer maker.There injection molds will be exported to all over the world, like Russian, German, Mexico, South Africa, South American...

The water dripper is an important irrigation device in the drip irrigation system, it is in accordance with the loe-pressure pipeline system and installed in the capillary on the emitter, the water and crops need nutrients drop by drop,evenly and slowly into the crop root soil.

The features of products:

1. High strength

2. Wear resistance

3. Anti-aging

4. Long life

5. The dripper has turbulent effect, anti-biological clogging,dripping evenly.

Below is the plastic water dripper mold specification,

1. Product: 32cavity water dripper mould

2. Product material: HDPE60%+LDPE40%

3. MFI: HDPE8 , LDPE70

4. Cycle time: 8S

5. Mold size: 800X550X480

6. Hot runner : Anole system hot runner

7. Gate: submarine gate

8. Steel (core and cavity): stainless steel S136 HRC45-48

9. Steel (frame):P20

10. Mold life: 10K

11. Character: Gear system high technology mold structure

12. Suitable injection machine: DKM350 servo motor

In order yo satisfy customers' all kinds of requirements, Sino Mould joint with Dakumar Machinery, can offer you turnkey projects. Welcome your enquiry for all types plastic water dripper mould.

Miya Qiu

E-mail: export@sinomould.com

whatsapp: 008615712676816

Skype: sino mould -Miya

China famous OE Mauto parts injection mold is very hot in China. so you will find many injection mould suppliers in our country. Sino was located in “China Mold Town”-Huangyan City, which is professional in all kinds of plastic injection molding solution. In order to develop and research different kinds of mold, Sino established several injection molding group. Such as Sino auto motive group, Sino packagegroup, Sino pipe fitting group, Sino home appliance group, etc.

All of the personin his group are have 5 injection molding technology at least. Some of them are very popular in China plastic molding line. Sino introduction talents steadily ceaselessly to guarantee our injection molding solution is perfect.

In order to satisfy customers’ all kinds of requirements, Sino Mould joint with Dakumar Machinery,can offer you turnkey projects, which means if you want to build a new plastic parts production factory, please don’t hesitate contact me to help you to drawing together. Our before and after sale service groups will be stand behind you to offer you the biggest support.

Sino’s professional technology is always available for you. send me messages if you need China OEM auto parts mold maker and other kinds of plastic molding solution.

Sales Engineer: Candy

whatsapp: 0086 15858685263

email: export@sinomould.com

So more and more plastic plant work with government to make suitable design wheelied bin , especially new investor who want to make new investment for new wheelie bin plant set up.

So what machinery do a wheelie bin production line needed ?

As a new beginner in wheelie bin plant field , you may be not how to start the project . do not worry , we are well know turnkey project of wheelie bin molding manufacture to offer customer with wheelie bin from 15L to 1100L, usually for daily used bin or industrial bin.

Usually , there are three important key equipments fo.

Firstly ,the wheelie bin moulds , including the wheelie bin body mould , bin cover mould , and locking clip mould and wheels mould, our factory are office high quality of bin mould for our customer , we use P20 or 718H as mould steel ,and the mould life can running more than 500K .fast cycle time .and perfect cooling .

Secondly ,Suitable injection machine ,for example ,we choose our DKM2200Ton machine for the 120L bin mould . of course , with 2200Ton machine ,it can produce many other plastic products ,such as pallet or big bucket .

Thridly :necessary auxiliary machine

Welcome to contact me for more information about your wheelie bin mould and machinery . we will offer you whole production line .

E-mail ;export@sinomould.com

Whatsapp:008615858629913

With the improvement of quality of life, people pay more and more attention to diet. For example, they may drink a glass of orange juice, apple juice, kiwi juice and other fruit juice every day, juice extractor is become more and more popular in our life, juice extractor has a lot of demand in the market, at this time, juicer mould also has big demand.

Sino has richexperience in home appliance mould manufacturing, such as juicer mould, washing machine mold, air conditioning mold, refrigerator mold, every year, we export more than 200sets home appliance moulds for different countries, such as Spain,Germany, Russia, Egypt, etc.

As we know, home appliance mould requires high precision, because there will have many plastic parts to form a whole. For example, orange juicer mould that we made before. As photoshowing, there are 22 plastic parts in single cavity or multi-cavities, with the different material of PP, PA, ABS, AS, etc. Such many components of theappliance mold, it requires high precise tooling machine, we have many precision tooling device which could keep mould has precision size, such as EDM, 5 Axis high speed cnc milling machine, etc.

For home appliance mould making, the most important is parts assembling and good surface effect.Sino is very experienced in household appliance mould making, we could effectively avoid unnecessary mistakes and to provide you with high-quality home appliances molding solution.

Any interests of orange juicer mould making, or other home appliance mould, welcome to contact me, we will be happy to offer you bestsolution.

Miss. Ysaline

Whatsapp: +86 1385763 5311

Skype: sino.pm

Email: export@sinomould.com

Multi-cavities 5 gallon cap die is popular in market as its high production ability and high quick benefit return. To follow time development, we aimed to provide 4-64 multi-cavities and 5 gallon bottle cap molds technology becomes mature.

What definite a good 5 gallon cap mould?

1.Design. Our cap design team had engineers which at least 8 years in 5 gallon cap molding. They knew suitable thickness, good tear system design for not easy broke and balance injection. Besides, mold designer provided simple structure which also had optimal coolingand air venting system.

2.Working experience. Each month,we exported 20-30 sets 5 gallon cap dies to all over the world. Mold makers are serious and rich experience.

3.Tooling equipment. We use S136 steel for cap mold core and cavity, and P20 steel for mold base. This could guarantee 1 Million-3 Million shots mold life. Besides, two times tooling, rough and precision tooling which ensure precision 5 gallon cap mould size.

4.Quality control service. QC willcheck after each step tooling. Once got green light, it could continue making.Besides, QC will check it’s smoothly running at least 8 hours.

More information regarding to 5 gallon capmold, pls feel free to contact email:export@sinomould.com

Post by : Stacy

Skype: sinogroupe-62

What’s APP:+8615168642559

As a professional manufacturer of injection mold, Sino can offer you all kinds bi-injection mold, for example,bi-color mold, bi-component mold, bi-material mold etc. We have rich experiments in the field of bi-injection mold making.

Bi-color plastic products is becoming more and more popular in recent years, because it can make the beauty product and saves production time and labor costs.

If you want to buy bi-color toothbrush mold, pls feel free to contact me. We will offer you the best solution for bi-color plastic toothbrush project. We can offer you not only bi-color toothbrush mold, but also bi-injection machine and other auxiliary machine.

For toothbrush mold, you need to pay more attention for the following points:

First, adequate surface hardness and wear resistance, in general, we will make heat treatmentof steel, by this way, mold can have a long mold life.

Second, high precision processing equipment, it can ensure mold with high precision.

Third, choose steel with good polishing performance.

Fourth, good thermal stability of the mold, etc.

More details for plastic bi-color toothbrush mold or bi-color molding project, please contact me, we will be happy to offer you best solution.

Miss. Ysaline

Email: export@sinomould.com

Tel: +86 138 57635311

Bucket are always used in industrial field . such as 20L lubricant bucket and 20L paint bucket .more and more investor turn their new project to bucket production line .

For starting a new 20L bucket production line, what need to we to offer for you for this bucket production line . first of all ,we need to make 20L bucket mould and Dakumar injection machine DKM650Ton ,we recommend servo motor machine to saving plant power .

For 20L bucket molding line ,the cycle time is 25 seconds , if with in mould label , the sueface will be like printing ,and can be many style , the cycle time is about 35 seconds , we have offered bucket production line for more than 50 bucket turnkey project for customers’plant all over the world .

For 20L bucket mould ,we apply P20 or 718H as the mould steel .with mould lifetime 500K . the suitable machine is DKM650Ton energy saving machinery , the auxiliary machinery including auto loader ,hopper dryer ,cooling tower ,water chiller .

We have rich experience in offering customer with all liter bucket molding line ,welcome to contact us for more technical information about bucket production line .

Whatsapp:008615858629913

How does bottle being produced , what material does a bottle applied ? how can a bottle plant can be set up.

today ,we will talk about how does a new beginner to start a bottle pet production line. New investor always confused how to start a new project ,when customer see our website he will have an idea how to start a PET preform production line and a bottle production line.

today ,we will talk about how does a new beginner to start a bottle pet production line. New investor always confused how to start a new project ,when customer see our website he will have an idea how to start a PET preform production line and a bottle production line.

Firstly ,the most important step is to start a preform molding production line.we can make PET prefrom ,the cavity number of the preform mould choose will according to the customer production capacity.take 500ml preform mould for example, 32 cavity 500ml ,the production capacity is about 4000pcs . the suitable injection machine is 380Ton machine. The cycle time is 30seconds . what is more ,we can offer auxiliary machinery ,such as water chiller ,hopper dryer ,auto loader and so on .

After preform mould and injection machine ready ,will make bottle production line ,we can offer filling machine and high compressor ,lower compressor and air dryer ,air tank to help for bottle production line .

If you have any new project about preform production line and bottle production line , we can offer the whole turnkey production line for you ,welcome to your any inqury or technical support !

Whatspp:008615858629913

More and more government are pay attention to the environment , they put garbage bin in every corner of the street.so there are big demand of the garbage bin ,and more and more investor want to invest money on the garbage bin production line . SINO Holding Groupe specialiazed in make garbage bin production line for every customers .

When customers want invest for garbage bin project ,we must remind them not forget in dealing with the customers who require a new mold that is not what they want but what they need,not 120L and 240L garbage bin mould are most popular in our daily life and industrial field . for 120L garbage mould can be produce in DKM2200ton molding machine , and 240L garbage bin mould can be produced in DKM2600Ton injection molding machine , if you want to produce 120L and 240L garbage bin mould one one machine ,customer can purchase only one set machine DKM2600Ton injection molding machine . SINO can offer garbage bin mould as well as suitable injection molding machine ,we can offer the turnkey project of the garbage bin.

For 120L and 240L garbage bin ,we usually apply P20 or 718H as mould steel to make the mould , and we can ensure 500K mould life . if you have new project about garbage bin production line , welcome to contact us for more information about gabargin bin plant set up .

Whatsapp:008615858629913

Plastic clothes hanger has many types, like PC transparent plastic clothes hanger, PP plastic clothes hanger, suit hanger, children clothes hanger and so on. And each type has many sizes and designs, so every year we can get many orders for plastic clothes hanger molds, and has accumulated rich experience.

Below is one kind of plastic clothes hanger mold specification, the customer require to make interchangeable inserts for another shorter sample.

1. Sample size: 44cm and 38cm length

2. Sample material: PS

3. Customer required color: black

4. Mold cavity: 4 cavity

5. Mold core and cavity steel: H13 with HRC32-34

6. Injection gate: 2 tip Anole hot runner change to submarine gate

7. Mold size: 650*600*500mm

8. Mold cycle time: 25seconds

9. Mold guaranteed life: Min. 1M shots

10. Suitable injection machine size: 250T

11. Delivery time for 1st samples: 60 working days

Except offer high quality hanger mold to customer, we also can help customer set up their plastic clothes hanger molding factory. The whole includes hanger mold, injection molding machine, water chiller, auto loader and so on. For more information, pls kindly contact me, Iam glad to reply you in detail.

Post by Miss Mandy

Email: export@sinomould.com

Skype: sino.mould

Sino Group hasaccumulated rich experience in supplying and exportingplastic auto part moulds to the whole of the world. With the improving of customers’ requirements for quality, precision and surface finish. In 2010 year, Sino invested 3.5 million USD for purchasing new tooling machines to realize improvement of the project high quality and high precision.

Why more and more customer find us and establish business relationship with us? Why our old customers always trust SINO and keep long business relationship with us? Why SINO Group grow up so fast? All because our mould quality is super, price is reasonable, service are best.

We pay high attention on five aspects of automotive mould:

1. Steel types: we choose suitable steel type based one product material, customer budget and mould guaranteed life required. If the product material is special, like PC or PMMA, but the customer budget can not afford like ASSAB S136 steel, then we will choose Thyssen KrupDIN1.2738 and so special treatment to make sure the mould guaranteed life.

2. Injection system: we adopt cold runner or hot runner based on the product design and customer requirement. And we had set up our hot runner factory named Anole, high quality and easy operation.

3. Injection gate location: for different auto parts have different requirement of the injection gate location, but all design must make the product looks nice and in high grade

4. Water channel design: water channel will affect mould life and cycle time, so must be intensive and big.

5. Surface finish: Sino team pay high attention on the design of parting line and the surface polish.

Welcome you down to our company, if you are interested in automotive mould. Please do remember that we can not only offer high quality auto part mould for you, but also can offer you the whole auto part production line.

Post by Miss Mandy

Email: export@sinomould.com

Skype: sino.mould

Whatsapp:+8615757610702