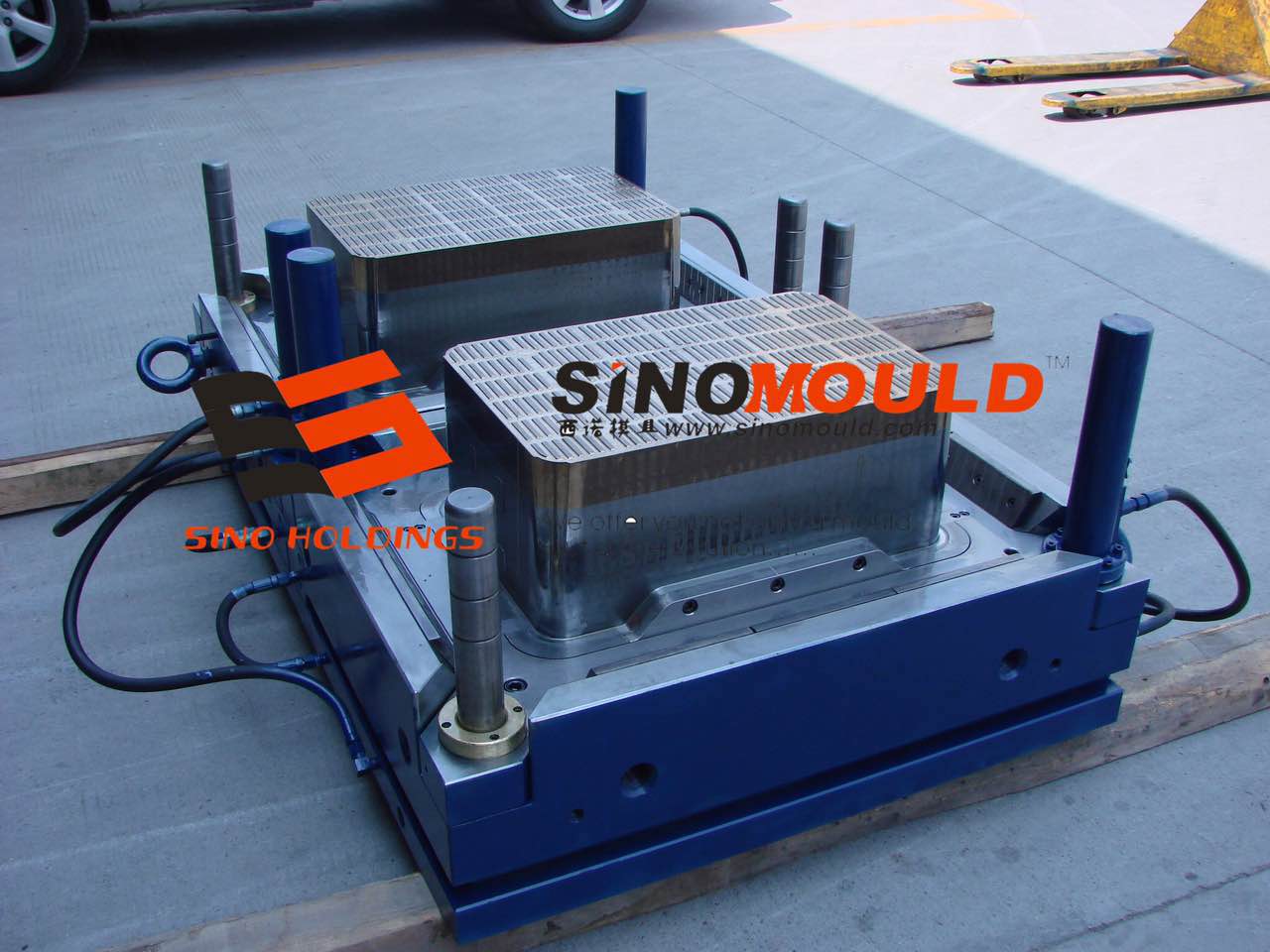

Sino mould has more than 24 years experience in the plastic crate mold manufacturing, especially in fruits and vegetables, bread , beer , coke , folding crate mold. Sino is a professional plastic crate mould manufacturer.

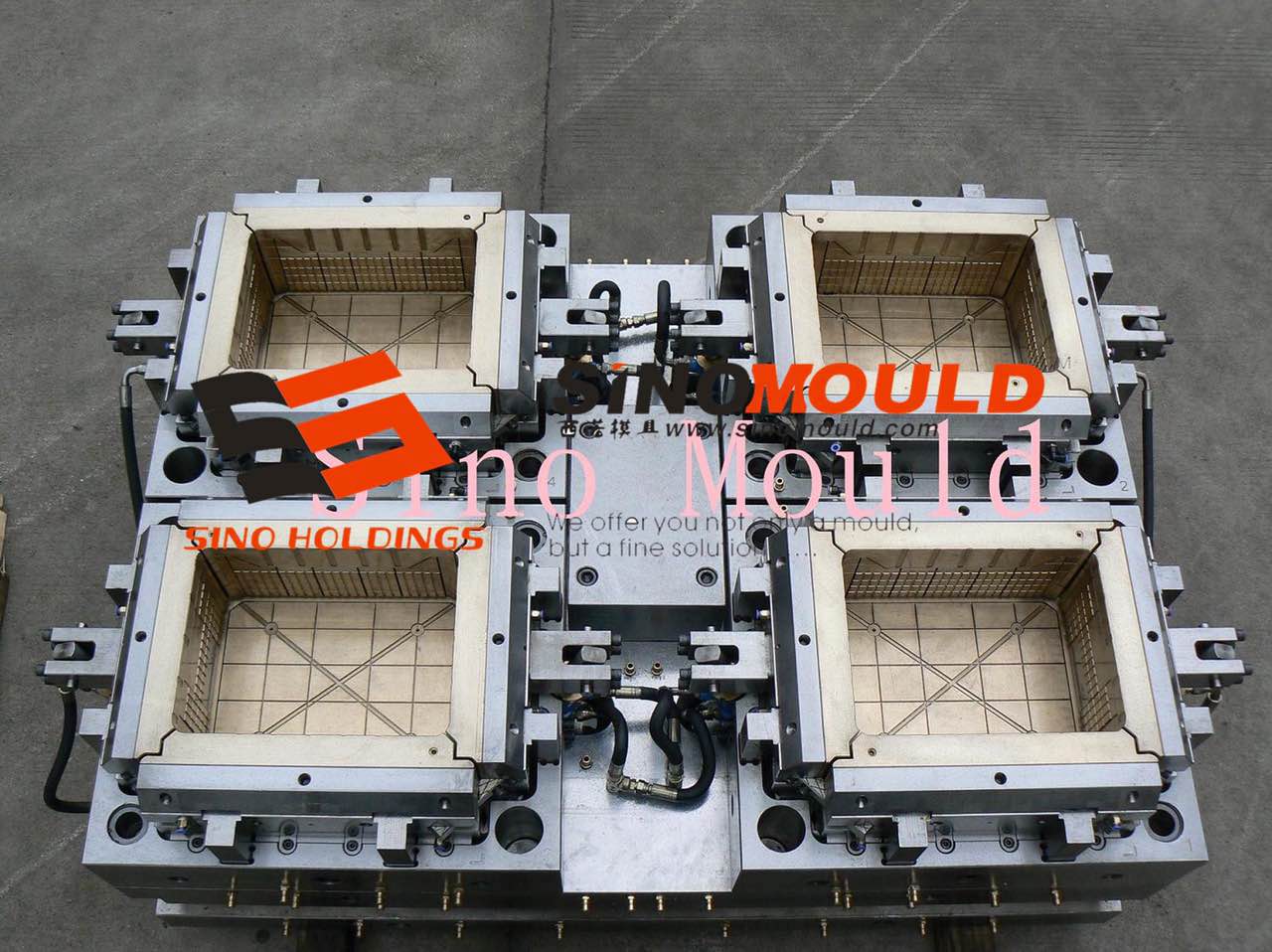

Most of the chinese mold supplier manufacturers, the goal is to provide customer with the high quality plastic crate mold. But we cooperate with Italy and can produce 4 cavity and 2 cavity plastic crate mold, Sino has provided 2 cavity crate mold and thin-walled crate mould to U.S. Customers. Sino export 100 crate moulds to the foreign market every year.

In Sino ,plastic crate mold is one of the most common and the most simple mould. We not only have our own mould production standard, but have its own design team and professional R & D team also.

For example: for the hot runner system, we also have own unique suggestion, such as one cavity crate mold, while for the 2 cavity and 4 cavity crate mold, hot runner we will suggest to use double, some crate mold can also use recycled materials, we have the filter design system to protect crate molding.

We always according to customer requirements to design the mould. We will ensure the molding cycle speed, hydraulic pressure. At the same time, in order to shorten our plastic crate mold production cycle time, we also specially made standard form, so that we can guarantee the quality of plastic crate mold, and can also save the mold production cycle. We also prepared some necessary mold components.

If you are looking for a plastic crate mould manufacturer, please feel free to contact me. Rose will offer you the best service with high quality.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Sino Mould has a wealth experience in basket mould making. We had made various kinds of basket moulds, such as Plastic laundry basket mouldshopping

basket mould, kitchen basket moulds,plastic baby use basket mould etc.

European market is raising for offering the plastic rattan basket, laundry basket with rattan design and so on. Colorful laundry basket mould is also very high precision mould. Sino Mould can offer you the topest quality and high speed injection, multi-cavities various basket moulds.

According to our experience, If you want to produce a 60L basket mould, the cavity we often suggest to use 1 cavity , and the mould size is around 800*800*980mm. The mould steel material is suggested to use P20, and the mould life is 800K at least , actually, it can run two times or even more than three times. For the injection machine, we suggest to use Dakumar 1600T injection machine .

Dakumar machinery is one of the members of Sino Holdings Group.And it is one of the world's most famous injection molding machine suppliers, exporters and manufacturers.

The runner system is suggested to use 1 points ANOLE pin-point gate, the ejection system is stripper plate from the injection side.

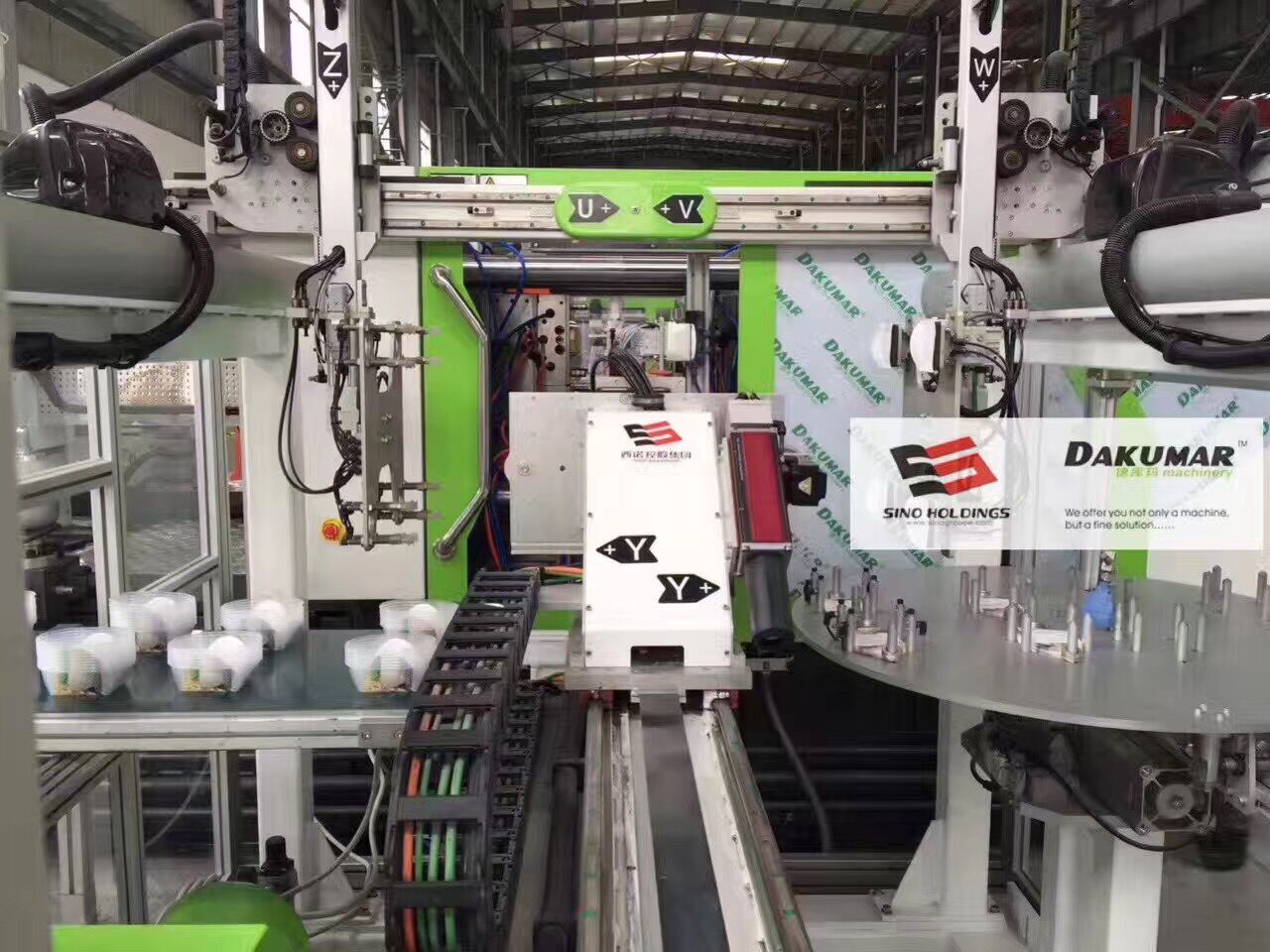

We always suggest customer to use the full automaticity for the mould. Mould features: Simple structure mould, Fine cooling system, Oil and water integrator is more convenient for application and operation

The injection cycle time is around 40 seconds.

If you are looking for a basket mould manufacturer, please feel free to contact me. Rose will offer you the best service with high quality.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Long mold life and easy operation play an important role when you judge a pet bottle mold good or bad. For satisfy this, we aimed to improve pet mold design with optimal cooling and air venting system. Besides, we will pay more attention on human friendly.

Plastic bottle mold divided into bottle injection mould and bottle blowing mold. Accord to per hour output, it could calculate mold cavities and decide mold steel application. Injection pet mold is better for using S136 steel, because this steel property had good polish ability. And take advantage of stainless,injection bottle mold could bear 5million shots mold life. The characteristic of our pet mold is dependent self-lock design which could avoid mold off-center. Besides, fountain water flow design in mold core, rotate water flow design in mold cavity, those will ensure optimal cooling system which greatly improve production ability.

On the contrary, pet bottle blow mold will use aviation aluminum 7057. And volume below 600ml, could design 2-8cavities which increased output double or three times.

More question regarding to pet bottle moulds, pls feel free to contact me.

From:Stacy

Email: export@sinomould.com

What’sapp:+8615168642559

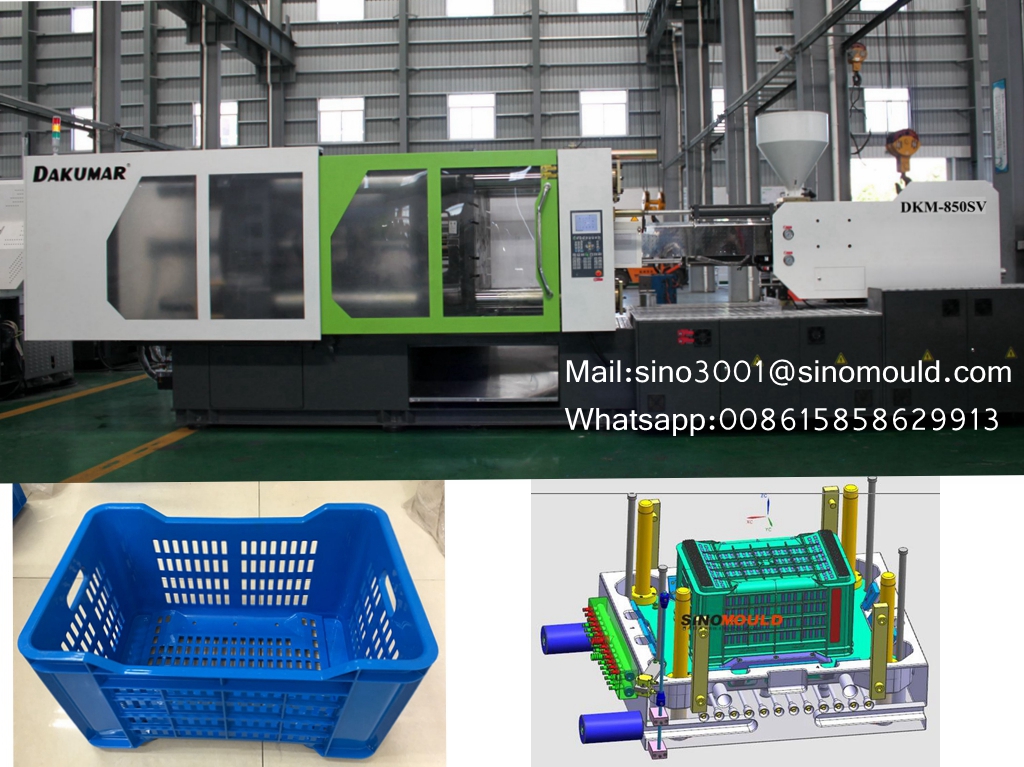

SINO HOLDING GROUPE is consist of SINOMOULD Darkumar machinery , which is aimed at offer a whole production line for plastic field customers . SINO MOULD is to offer plastic parts mould .such as crate mould .chair mould .table mould .buckets mould or some customerized made design moulds , meanwhile , our design team have a stronger ability to research and development for crate mould new design according to customers idea and simple samples .

After design confirm .we use suitable mould steel to make the mould .to ensure crate mould high quality and perfect coolingsystem tomake the crate mould running for long.

Dakumar machinery make various types plastic injection molding machine . including high speed injection moldingmachine .servo motor energy saving and standard injection molding machine .

The crate machine tonnage can be range from DKM50to DKM4000 .but from middle size crate mould .such as 530*360*280mm crate . we usually use DKM650Ton machine toproduce the 530*360*280mm crate mould . each day can produce 2000pcs . whichcan help you earn money by plastic crate fast .

Our factory have rich experience in offering customer with crate turnkey project .including crate mould ,suitableinjection machine ,and other auxiliary machineries .welcome to contact me formore information .

E-mail:export@sinomould.com

Whatsapp:008615858629913

Here extending ourwarmest invitation to your visit of SINO exhibition in Canton Fair will beheld on 15th-19th April, Guangzhou. Our booth No. is 1.1A13-14 B11-12.

By that time, SINO HOLDINGSwill show our latest technology of

* Hybrid Injectionmolding machines

* Injection moldingmachine Servo Models

* High quality andgood design molds

* Robot system

* Variousof turnkey solutions for newly start plastic factories

SINO has accumulated richexperience in offer customer with the whole turnkey production line, includinginjection mold, suitable injection molding machine, robot system and somenecessary auxiliary. So far, we have delivery more than 100 turnkey production projects to many countries, the production line we offered could be range fromIML paint bucket production line, table production line, pallet productionline, PVC pipe fitting production line etc. And we have agents in 12 countrieswhich can offer after-sales service and technical support to our customer atthe first time.

Welcome your visit and lookingforward to meet you there. If you have any new projects, please feel freeto send us enqiury, we will offer big discounts for you. Thanks for yoursupport to SINO HOLDINGS.

Post by Miss Mandy

Email: export@sinomould.com

Whatsapp:+8615757610702

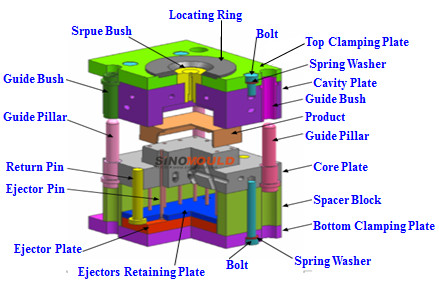

Do you know most of products were produced in the mould? Do you know what the mould is? It’s simple to say that it is a tool to make products. In China, we also called “money printer”. Let me show you mould parts function.

1.Locating ring: locating ringis a circular member, which is used to locate the mould in the center of the injection machine to ensure proper alignment between sprue bush and nozzle, so that eliminating leakage.

2.Sprue bush: it is the connecting member between the machine nozzle and mold face, and offers suitable hole that make material force into the runner.

3.Fixed clamping plate: It holds The fixed side of the mold to the fixedplaten of the injection machine.

4.Fixed cavity plate: It used to hold the fixed cavity block, leader pin/bushing and sprue bush.

5.Movable cavity plate: It was used to hold the movable cavity block, leader pin/bushing.

6.Movable clamping plate: It holds the movable side of the mold to the movable platen of the injection machine.

7.Cavity and core: These two parts is very important in the mould. It can affect the products shape and quality of the products.

If you want to know more mould parts function, welcome to contact us.We can offeryou more information, because we know the mould parts function.

Email:export@sinomould.com

Whatsapp/mobile:0086 15215806623SINO HOLDINGS GROUP is a well-knownplastic mold manufacturing High-speedInjection Thin Wall Mold, we custom production of various highefficiency, high difficulty, high precision plastic mold business. It is notjust a professional plastic mold manufacturer, we provide customers not onlymold and machine, but a fine solutions.

Sino mold high-speed injection thin wall technical points:

1.Special design of injection mold for slim zerofour buick system;

2.High-precision machining process;

3.Mold parts selection of steel materials;

4.Exhaust system designed specifically forthin-wall molds;

5.High speed injection system;

6.Mold sticker design.

When we tested mold, the maintenance in the place. SINO MOLDwill down to every mold in detail.

All mold before shipment, we will arrange virtual moldproduction for instance, some molds will last 24 hours or some large molds willarrange for continued production of 4 hours or more. we advise customers tocarry out large quantities of trail production at SINO to ensure the mold areable to produce properly after reaching the customer’s company.

We are pleased to welcome you to SINO mold technology,solutions, services, experience and quality control system will let you have astrong interest in us.

If you are also interested in High-speed Injection Thin Wall Mold, pleasefeel free to contacted Miss Nancy.

Posted by Miss Nancy

WhataApp:+8613758679372

Skype: sinomould-01

Email: export@sinomould.com

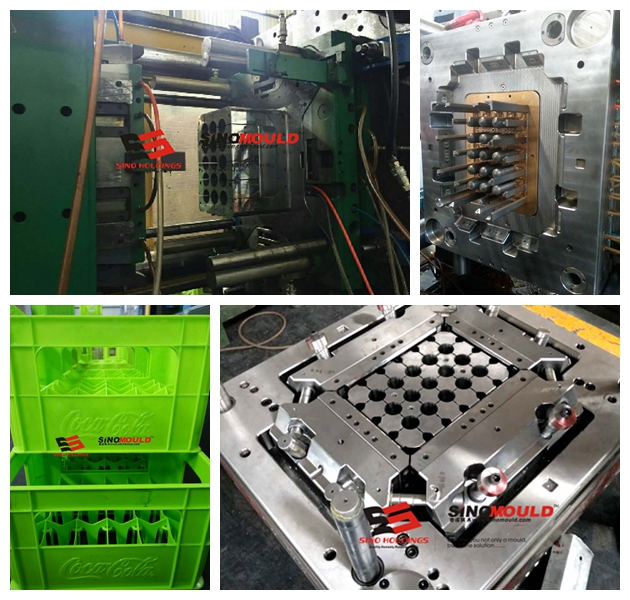

Ideal for glass bottle transportation, all bottle crates must be logistical packaging, offering both maximum protection and ease of handling to operators,robots and customer. So tailor made glass bottle crate molds play an important role in achieving a good end product.

From long cooperation with European clients, like Shcoller Allibert, our crate molds stacking and dimension meet European standard, it is widely welcomed by our high quality level customers. Mould cooling time in crates moulds is biggest factor to be considered for highend productions. Different form many tool makers, our customized cooling systems designed for different beer crate structure. Our optimization cooling system of water nozzle size, cooling line material is designed for every part separately. Suitable cooling system can short your bottle crate molding time ,save many thousand dollars during mass production. Meanwhile, good quality mold steel, reasonable bottle crate structure, high precision tooling all are mainelements for end product. Attached picture shows Sino 24-bottle crate molds for Pepsi and CoCa Cola.

Our branch ,Dakumar Machinery, manufactures your target injection molding machine for beer crate, soft bottle crate,water bottle crate, beverage crate production. Equipped with comprehensive necessary devices. Warmly welcome your contact and visit to know well our strong ability and good quality with service.

Posted by Ms. Helen

Skype:sino.group10

Email: export@sinomould.com, export@sinomould.com

Phone number: 0086 15858625783 ( wechat, whatsapp)

Our company is leading in manufacturing PET Preform Mould from single to 144cavities over 20years in China. Now let me show you our PET preform mould features.

1.Steel:

Cav/cor steel: we use S136 stainless steel, made in Sweden, the HRC hardness 48-52. This steel can be anti-rust and acquire substantial accuracy and fantastic quality; excellent polish feature and make sure the mould guarantee time.

Mould base steel: DIN1.2311 with precise grinding machine with each plate thickness tolerance 0.015mm for a plate size 500*500*400mm, the hardness 32.

2.Injection Gate

Injection gate: we use valve gate with hot runner system. In addition, I also know that some customer use short tail or long tail in the mould. But we don’t suggest do that.

Vale Gate VS Short/Long Tail

Using valve gate with hot runner system: 1). It can save material;

2). It’s easily for material flowing and having beautiful surface;

3). It needn’t worker to cut down the tail, so that saving labor cost.

4). In the early stage, the mould of valve gate cost will be a litter higher than short/long tail mould.

Using short/longer tail: 1). It will be waste material than valve gate.

2). It has tail and need worker to cut down the tail, so that increase labor cost.

3). Short/long tail will be broken in the mould, later maintenance will be difficult.

4) In the early stage, the mould cost will be cheaper.

3.Mould Guarantee Time

In China, most of preform suppliers offer the mould guarantee time is 2 million shots, but our mould gurantee time is 5 million shots, the quality guarantee time is 2 times longer than most of PET preform mold makers.

If you are looking for PET preform mould supplier in China, welcome to contact us. We have 100% confidence to offer you mould with high quality and best price.

Posted by Sara

Email: export@sinomould.com

Mobile/Whatsapp: 0086 15215806623

SINO HOLDINGS GROUP is located in the beautifulscenery of the mold town----Huangyan, we are one of the Chinese famous mould supplierin

foldablecrate mold, home appliance mold, automotive mold and other plastic moldinjection.

We have more than 600 employees, with strongtechnical development strength and rich experience in manufacturing, to provideusers with high-quality products and improve the technical services in thedomestic counterparts enjoy a high reputation.

The company was founded in 2000, we have more than 20 years to constantly update the technology, and constantly improve the management and development into a modern management philosophy, the strength ofmodern production model enterprises. The introduction of the international advanced CAD, CAE, CAM technology system, with CAD/CAM graphics workstations,drawing machines. We used C-mold software for plastic flow analysis and surfacesoftware system for reserve engineering design, can quickly adapt to the needsof domestic and foreign customers.

The full implementation of ISO9001 standard,the implementation of 6S site management. Now more than 90% of the products areexpected to the Middle East Countries, South America, Europe and the UnitedStates. And we set up strict quality assurance system and professional andtechnical standards to ensure the foreign customers worry-free.

We are the Chinese famous mouldsupplier , pursues“people-oriented, quality win” business purpose. If you want to establishedwith us. We will warmly welcome you to my company.

Posted by Miss Nancy

WhataApp:+8613758679372

Skype: sinomould-01

Email: export@sinomould.com

Plastic cap are widely used in our life, plastic caps has big demand in the market, for example, various water cap, plastic drink caps, cosmetics caps, etc. Sino has rich experience incap molds making, we could supply you best solution for plastic cap molding project.

For cap mould,usually we choose S136 as mold steel with hot runner system to keep good surface effect and save raw material. Before, We have made mold with 8 cavity,16 cavity, 32 cavity, 72 cavity, 128 cavity, etc.

There are two main ejection ways for cap mould, one is ejection by stripper, and the other is unscrewing,it depends on depth of thread. when the thread depth is greater than 1.2mm and thread continuous, will choose unscrewing ejection system, otherwise ejection by stripper. For unscrewing system, usually have two ways to reachthis action, one is by motor, the other is mechanical chain, by this way, itcan ensure thread not damage.

Here show you somephoto of our plastic unscrewing cap and molds, for you reference.

More info for unscrewing cap mould, or multi-cavities cap mould, pls feel free to contact me, we will be happy to offer you best unscrewing cap molding solution.

Miss.Ysaline

Whataspp: +86 1385763 5311

Skype: sino.pm

Plastic injection molding turnkey service and equipment supplier-Sino Holdings Group offering plastic sofa chair injectionmolding equipment, we will help customer fromset up factory form zero about sofa chair produce.

Plastic Sofa chair, rattansofa chair are popular in plastic market, many customer are invest for such goodand attractive project, for total budget seem is more in the beginning, but theReturn of interest if fast. And for the equipment for plastic sofa chairinjection molding, you also can use this injection molding machine to produceother big plastic parts, such as: industrial dust bin, plastic car bumpers,plastic pallets, large industrial products etc…

We had customized some turnkeysolution for sofa chair injection molding, customer from Brazil, Argentina,Chile, Morogo, Mexico and so on…

plastic sofa chair injectionmolding equipment including: Injectionmolding machine unit, plastic mould unit, robot and auxiliary equipment.

Injection Molding Machine Unit:Considering sofa chair have Single person sofa, double sofa, and tea table,roughly we recommend DKM850T,DKM1350T and DKM3350T machine for injection parts,also you can use it for inject other large size parts.

Plastic Mould Unit: Singlesofa mould, Double sofa mould, and tea table mould steel by P20 steel, with 200to 300 thousand shots.

Robot And Auxiliary Aquipment:robot for take out part from injection machine, and other auto laoder, chiller,dryer and so on we will considering all.

Stand on customer site, thebest service is very important for such turnkey project, our team can supportcustomer before order and after-sales, training, installation and so on. If youare looking for a supplier for plastic sofa chair injection molding equipment,please contact us:

Email: export@sinomould.com

What’s up: 0086 15858625783