There are many China PVC PPR pipe fitting mold maker, Sino-pk is one of them. How to be a good pipe fitting mold supplier in China? we have the following requirement to ourselves:

1.Have rich experience in pipe fitting injection molding, not only in plastic mold, but also in injection molding machine. He should have the ability to know how to make the mold andmachine can work together very well.

2.Can offer customer a pretty good injection molding solution about PVC PPR pipe fitting before tool making.

3.Process the mold with good and reasonable equipment to control the cost and make sure the mold precision and quality.

4.There’s QC department to control the mold sizes after each process steps.

5.Finish the mold in time and in best condition.

6.Make trial production in seller’s factory for more than 5 hours. To make sure the mold or even machine can work very well in customers’ factory.

7.Offer immediately feedback in the after sale service. And solve the problem within 24 hours.

8.Engineers are always ready to send to buyer to help customer solve problem in any time.

Do you have more suggestion about to be good China PVC PPR Pipe fitting mold maker? Welcome to contact. Let’s grow up together in 2017 year.

sales engineer: Candy

whatsapp: 0086 158 5868 5263

skype: anole-hc-02

Sino Holdings Group could offer high quality flip top cap molding solution for our customers, every year we export more than1000 cavities flip top cap moulds (include inside closing system & generalnot automatic system), at same time, we could supply suitable injection molding machine for flip cap production.

Nowadays, flip top cap are widely used in our life, such as Shampoo cap, toothpaste cap,cosmetic cap, etc. Flip top cap mould become more and more popular in the market. Many years’ experiences of flip cap mold making, we could supply you the best molding solution.

For example, one of our auto closing flip top cap mold information as below:

Mouldcavity: 4cavities

Runner system: 4 points Anole hot runner

Mould size: 500*450*480 mm

Cycle time: 9s

Ejection way: automatic flip top close & fully-automatic drop

Mold life: more than 10M shots

Mould steel: S136 for core & cavity

Recommend machine tonnage: DKM250

We choose S136 as mold steel, tempered with hardness HRC40-44 to ensure long term mould production, Our hot runner system—Anole, use German heating elements,could supply the optimal heating effect. For Injection molding machine, usually for cap mould production, machine type is DKM180, DKM250, DKM330, etc.

If you are looking for flip cap molding line supplier, pls feel free to contact us, we will be happy to offer youbest solution for molding projects, and include injection molds, injection machine, and necessary auxiliary machine.

Miss.Ysaline

Whatsapp:+86 138 5763 5311

Email:export@sinomould.com

Sino Mould is a professional mould manufacturer for the large size injection mould making, we could supply high quality bumper mould for OEM factory and after sales market. Our mould have shipped to many different countries, such as Brazil, India, South Africa, Turkey and many other countries.

For the bumper mould, according to customer requirement, we use P20/718H steel material for the core and cavity, if for OEM mould project, we suggest use imported steel material with DIN1.2311/ DIN1.2738 and other good steel material. Usually the mould is designed with valve gate hot runner system and also hot runner system with edge gate type, it is better for the big parts injection molding. At the same time, we also supply the fixture for the automotive parts.

For the bumper mould making, we supply one stop service, from the product design analyzing, Moldflow and mould design inspection to mould tooling, sample checking and testing. If you need more information about the automotive mould, welcome to contact us.

As a group company, we could offer turnkey project for the bumper molding line, include injection molding machine, bumper mould supply with other necessary additional machines. Thanks.

Post by Miss Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

whatsapp: 008615257606120

SINO HOLDING GROUP has rich experience in making home appliance mold. Weare a professional mold maker with almost 20 years. We offer the home appliancemold design and various beer crate speed injection molding solutions and withcompetitive price.

As Chinese famous brand injection molding supplier, SINO MOULD has richexperienced team for different kind home appliance projects with mold andinjection molding line. Like hand dryer molds, refrigerator mold, fan mold, airconditioner mold……

During 11 years of SINO team’s creating, we got to know that theworkmanship in the most important at that time, we know the workers who aredealing with air conditioner mold or other home appliance molds, we trust thattheir quality mentality will be better than the people who are dealing withmotor cycle molds… from that time our HR department choose the people who cameto SINO. Most of top managers and designers were deal with home appliance moldor other molds, until now we have made many air conditioner molds or airconditioner housing molds, air conditioner mask molds, air conditioner fanmold, air conditioner grille molds… we use DIN1.16 tempering steel for cavitieslong lasting polishing and DIN 1.2738 for the core side.

If you are interested in homeappliance mold, please feel free to contact Miss Nancy.

Skype: sinomould-01

E-mail: export@sinomould.com

WhatsApp: +8613758679372

SINO HOLDING GROUP was established in 2007, we are one of the Chinese famousplastic molding supplier. Since itsinception to now, we have been committed to the injection molding machine,mold, consumer electronics production development, production, sales andservices. We have a strong team of work, as for we have more than 50 engineersare committed to the development and research of the latest mechanical molddesign, the existing structure of the continuous upgrading and improvement. Nowwe have more than 43 different new projects in the success of research anddevelopment, including mold structure design, machinery manufacturing,high-tech, electronic products and so on. Not only these, we can also providethe customer with support, with a fine solution.

Our main products: plastic mold, injection molding machine, plate,pallet, car mold, lamp mold, bumper mold and so on.

We will offer you all the information of the products dimension,components material suggestion, packaging suggestions. We even can help yourpackaging solutions from design to the sampling.

We have excellent management measures and quality of the concept. Wewill uphold the technology, quality driven, develop of the concept, andcontinue to create to a miracle. We sincerely welcome your presence, let uswith a sincere enthusiasm for a better tomorrow. We are the Chinese famous plastic molding supplier.

Posted by Miss Nancy

Skype:sinomould-01

E-mail:export@sinomould.com

WhatsApp:+8613758679372

Sino mould is a professional chair mold manufacturer for more than 20 year. And we are ranking on the top of international plastic chair mold supplier. We can make 150 pairs of chair molds every year. Until now, we have done more than 3 thousand pairs of chair mold. We have rich experience in making plastic gas-assisted chair mould and we have our own equipment for Gas-assisted chair mould injection line and plastic molding machines.

Below is the Theory of the Gas - Assisted Injection Molding.

1. After the mold is clamped, the plastic is filled the mold cavity area.

2. After the set time interval, the first stage is the injection gas.

3. The second stage relapses the plastic to compensate for the plastic shrinkage caused by cooling

4. There will be a uniform pressure in the plastic

5. The mold will disappear before the mold is opened

6. When the nozzle valve is closed or the gate is solidified, the plastic will be filled again

These are some detail information about the mould which we have ever made:

Product size: 63*52*78cm

Runner: hot runner

Gate: side gate

Mould steel:718

Cycle time: 2-4minutes

We also have a professional design team and production department, if you need a high speed, high quality plastic gas-assisted chair mould, please contact us, we guarantee that you will be very satisfied with our products.

Miya Qiu

E-mail: export@sinomould.com

whatsapp: 008615712676816

Skype: sino mould –Miya

SINO HOLDING GROUP has rich experience to help customers set up a factoryfor plastic bi-color hamlet. We area professional mold maker with almost 20 years. We offer bi-color machine,hamlet mold design and auxiliary machine with competitive price.

Wecould not only to provide hamlet, we can offer you tableware, some stationeryproducts. Some customer would like us to offer quotation for Bi-color injectionmolding solution at first, we will list what info necessary for setting up aplastic marking factory. Which could help us offer the best solution with themost competitive price for you.

1.Factory building:

Buildthe construct. Layout of the injection molding machine can be offered.

2.Voltage for machine working:

It’simportant for machinery, different countries have different voltage.

Product

3.Please show me the Bi-color product you want.Send me the pictures, size, materials and so on.

Combined with our injection molding machine andmolding company, we can provide a perfect solution, as long as you will beasked to tell us, we can design your robot according to product requirements. Ourrobots are safety, stable performance, easy to use with reasonable price. Nowmore and more of our old customers are trying to use PlasticBi-color hamlet.

If you are interested in this typeproduct, please feel free to contact Miss Nancy.

Posted by Miss Nancy

Skype:sinomould-01

E-mail:export@sinomould.com

WhatsApp:+8613758679372

Each PET bottle has a suitable plastic cap , a suitable bottle cap can enhance the appearance of the bottle. Sino Mould is a professionalPlastic Flip Top Cap Mould supplier in china. We have gathered rich experience in making ideal injection mold and flip top cap mold with high quality hot runner & cold runner.

Our cap mold has many merits:

1. The type is complete, such as 24cavity, 32cavity, 48cavity and 72cavity, ect.

2. Each cavity is interchangeable with high accuracy dimension control.

3. Steel material is S136 with good polishing and long time running.

4. Special design in nozzle.

5. All the part are manufactured through CNC equipment.

Below is the plastic flip top cap mold specification:

Mould Steel:S136

Cycle Time: 22s

Runner: cold runner

Gate: point gate

Ejection System: ejector pin

Suitable Machine: DKM-300HH

In our website,you can find the corresponding molds for making various caps.If you have new plan to invest into plastic flip top cap mould industry, welcome to contact us,we could offer favorable price with convenient service to you.

Miya Qiu

E-mail: export@sinomould.com

whatsapp: 008615712676816

Skype: sino mould –Miya

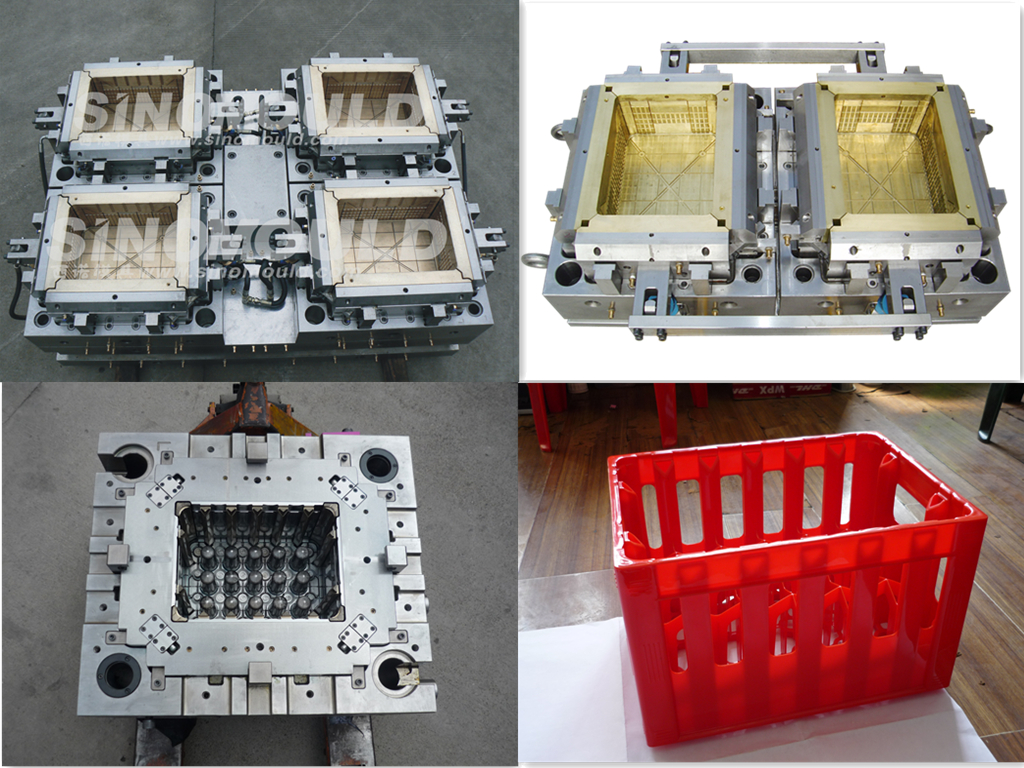

SINO Mould is a plastic crate mould manufacturer maker from about two decades. We have developed more than 2,000 different types of crate mold, such as bottle crate molds, fruit crate molds, bread crate molds, fish crate molds, vegetable crate molds, molds , etc. In particular, we have developed the crate with 2cavity and 4cavity. This is the first in China's mold industry

Now, more and more plastic crate widely used in factory production workshop instead of wooden box. Most of the crates are used in machinery, automobiles, home appliances, light industry, electronics and other industries. It can be used for storing foods and easy to clean, some small part can easy to turnover. Their reasonable design、excellent quality are suitable for transport, distribution, storage, circulation processing and other sectors in the factory logistics.

Regarding the crate mold, it’s suitable for servo injection molding machine, and the cycle time of general crate is around 30s, one-off thinwall crate is around 15s.most of crate is made of HDPE.

How to make the crate keep longer working life?

First:Choose the suitable steel production mold and main part of the mold. For the crate mold with 4 cavity ,we use the steel material to do mold which must be higher than 45 pre-hardened.

Second:Hardening of steel material must control the hardness of steel, not too high. The part of mold (like slider and guide) must be use equipment for precision machining.

Third:Make sure the cooling system is at its best.

If you are looking for plastic crate mould,please fell free to contact us,we won't let you down.

Miya Qiu

E-mail: export@sinomould.com

whatsapp: 008615712676816

Skype: sino mould –Miya

SINO HOLDINGS GROUPE is the most famous and extensively experienced in the field of providing complete production line regarding plastic Bottle production . With two magnificent branch company , SINO MOULD- having more than 15 year of experience in manufacturing PET mold and blow mold and DAKUMAR Machinery - having more than 20 year of experience in the field of PET preform injection machine, has been able to erect big business empire in the world market.

We are truly specialized in providing quality and costeffective solution for whole bottle production line. We offer tailor made project as per customers requirement like preform design, neck size and bottle design for water , oil, vodka,jams,sauces, medicines etc.

We are dedicated to help our clients, to act as their technical adviser and to deliver individual solutions tailored to specific business need and challenging budgets. We are capable of meeting all small, medium and large scale requirement of organization, with professionals responsible for plant setup and necessary analysis.

SINO HOLDINGS GROUP is your best packaging partner for your glorious success.

For any further information please dont hesitate to connect.

Rahul Shah

export@sinomould.com

whatsapp: 008613989381153

These days trend of using plastic furniture has been increased rapidly . Plastic furniture has been able to take big market success. Plastic furnitures are light weight , durable, water proof ,easy to transport, cheap to buy , beautiful and can be made in various color and design, mostly used in catering, garden , home and offices .Due to which plastic chair has become one of the most important furniture and key point for business investment.

SINO MOULD is leading mould manufacturing company in china and we have professional team of engineers for plastic chair mould design and melt flow analysis .We annually produce 300 sets of plastic chair mould which includes Gas assistant chair mould, PC transparent chair mould, Arm chair mould, Armless chair mould, Rattan chair mould,High back chair mould,Relax chair mould,folding beach chair mold, sofa mould ,Table mould,Round table mould,Rectangular table mould, Square table mould, Stool mould, Baby stool mould , Kids table mould , Child table mould , Baby chair mould and also chair mould with back insert changeable design for different versions and different seat insert.

Demand of fashionable and unique design of plastic furniture is increasing day by day. SINO MOULD can provide complete and cost effective solution regarding plastic chair mold of any kinds of customer’s own unique design conveniently.

Rahul Shah

email: export@sinomould.com

whatsapp: 008613989381153

Nowadays, more and more people like to use the plastic storage box. And its popular all over the world. Sino Plastic storage box mould is your best trust. Sinois focus on various kinds of moulds manufacturing.

How to become a good mold manufacturer?

1. Reasonable mold structure design, and can provide high quality and yield.

2. It needs a good cooling system to reduce the product molding cycle.

3. Own a good polishing effect to improve the surface quality of the product, as well as smooth demoulding.

4. Robot can be used to complete the whole process of production in order to improve the whole production quality.

We are an experienced plastic storage box mold, storage box production line supplier, own more than 20 plastic products production line construction history, distributed in Europe, North America, South Africa and other countries.

We can always provide customers with plastic molding, solve various problems of the full production line. And we provide customers portable, rapid technical support and services. We are looking forward to more relevant customers to contact us to explore plastic molding and other technical problems and projects.

Sino is experienced in plastic storage box mold manufacturing.We are China's leading storage box mold manufacturers, specializing in the production of various storage containers mold. We have a wealth of experience in the multi chamber storage boxes, such as 2 and 4 cavities.

Recently, we have made4 sets of storage boxes, specifications for the 570 x 400 x 420mm mold, the production cycle is 24 seconds, the wall thickness is 1.6mm, the tolerance is not more than + / -0.03mm. And the steel material we suggested to useDIN1.2738, because the 2738 steel mirror polishing effect is very good. At the same time, the service life of the mould is longer than others.

If you are looking for plastic storage box mould, please feel free to contact me. Rose will offer you the best service with high quality.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype:Sino mould-Rose