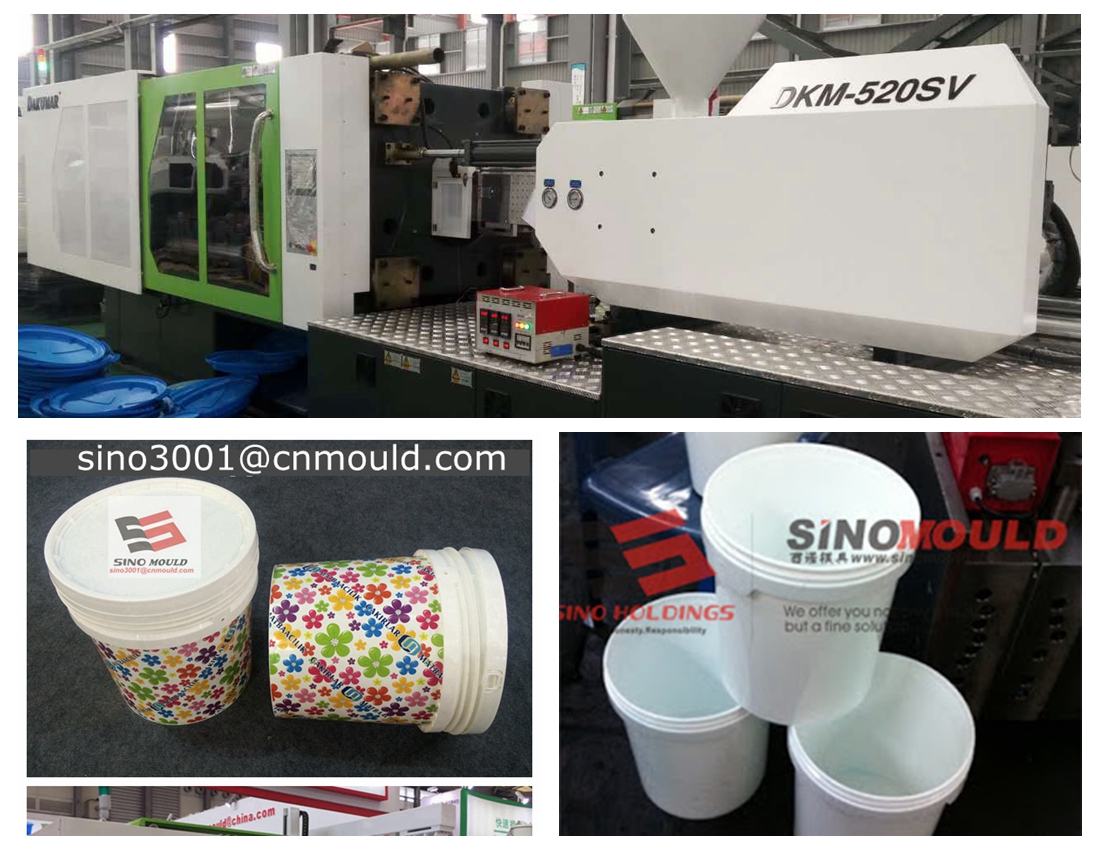

Canton Fair exhibition for machinery and equipment will held in Guangzhou again from April15th to 19th,2017, SINO MOULD and Dakumar Machinery will attendthe exhibition as exhibitor .

As an well know mould maker and top quality of injection molding machine . SINO HOLDING GROUP aimed at offer our customer with whole turnkey production for all kinds of plastic parts ,including help them set up their new factory to start mass production .

As thin wall containeris more and more popular,and its investment can easy get back profit fast . we will display the most popular thin wall container mould line in the exhibitions .

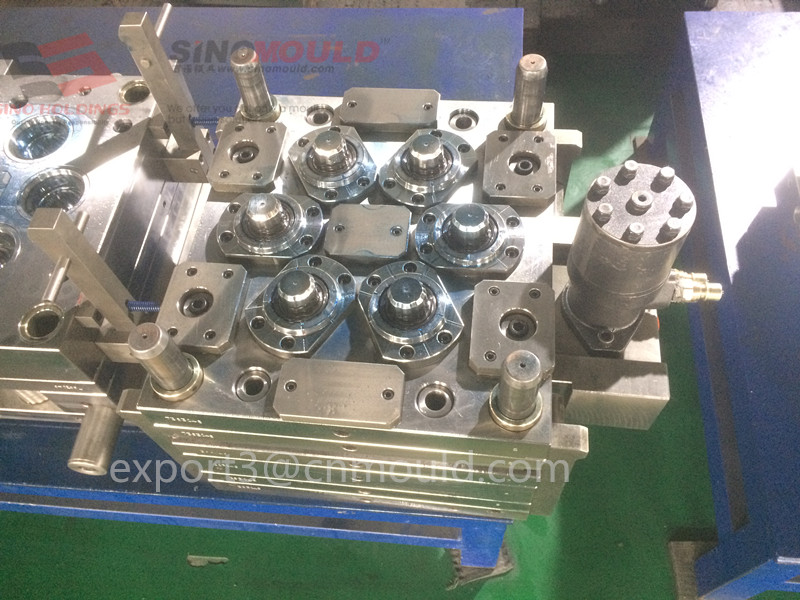

14 cavity thin wall container mould . which apply S136 as mould steel .the mould is high polished . and can make more than 2 million shots of mass productions .

2200HHi njection molding machine apply the accumulator ,which have injection more fast than normal servo motor injection molding machine .

3)IML robotsystem .which can lower cost than other pre-decorating methods .

Dakumar has offered more than 30 sets ofturnkey project for The in mold labeling system are including:

450ml round juice cup whole IML system toUzbekistan:- The cup size is Up¢95*110mm, Bottom: ¢ 68*110mm,thickness is 0.6mm,two cavities cup mould with valve gate, themould size is 566*366*495mm,it run on DKM188 high speed injection machine andside entry robot fromItaly, the cycle time is 6 seconds.

Welcome to visit our CANTON FAIR boothnumber 1.1A 13-14 ,and contact Selinda for more information about your plastic molding line .

Contact:Selinda

Mail:export@sinomould.com

Whatsapp:008615858629913

Plastic water cap are widely used in our life, such as NongFu spring, Master Kong,c’estbon, all of this brand is sale for natural mineral water, Sino has rich experience in supplying water capmolding line project, we could offer you best solution.

Usually, for plastic water cap, diameter is 28mm, raw material is PP or PE, and formold, in general, we will choose hot runner system with point gate, mould steelis S136. As we know, for cap mould, there will have safety ring, usually have two ways make it. One is made by mold insert, when production, you can got cap mould with ready safety ring, the other is made by cutting machine, after cap production, use cutting machine to cutting it. Compare with this two way, we prefer to suggest make insert, by this way, you can save more time.

We have made more plastic water cap mould, for example, before we have made 72cavities cap mould, used by DKM520sv, mold safety ring made by insert, cycle time around 25s. we could offer whole line for cap mould production, include plastic cap mold, suitable injection machine, and necessary auxiliary machine,such as chiller, dryer, auto loader, etc.

Ifyou are interested in plastic cap molding solution, or you are looking supplierto help you start water cap & water bottle molding project, pls feel free to contact me, Sino will be happy to offer best solution for you.

Skype:Sino.pm

Whatsapp:+86 138 5763 5311

What is in mold labelling pail ?

In-mold labeling is a pre-decorating technique usedworldwide for blowmolded bottles aswell as injection molded and ther moformed containers or other plastic objects.Pre-decoration is the application of a label to a container before it is filledwith product. SINO HOLDING GROUP is consist of SINO MOULD and Dakumar machinery.we are making customerized in mold label plastic parts as well as injectionmolding machine .such as IML bucket production line.

So far,SINO factory have helped customers who are newin mold label bucket or in mold containers ,we help to establish their plastic IML pail plant for more than 100 turnkey projects .including paint bucket with IML system .IML paint bucket molding line,table and chair molding line .etc .

SINO have rich experience in assisting you establishyour plant from zero .such as IML paint bucket molding line . we can offer youwith

-IML bucket molding budget analysis .

-All IML molding equipments,such as customized IMLmould .suitable IML bucket molding injection machine.in mold label robotsystem.all necessary auxiliary machines.

-Plant drawing of water ,air ,and design /layout .

If you have experience in mold label bucket orcontainer ,or without any experience,welcome to contact us for more informationabout your news IML projects .we will offer you the whole turnkey productionl ine .

Contact:Selinda

Mail:export@sinomould.com

Whatsapp:008615858629913

What is in mold labelling pail ?

In-mold labeling is a pre-decorating technique used worldwide for blow molded bottles as well as injection molded and the rmoformed containers orother plastic objects. Pre-decoration is the application of a label to a container before it is filled with product. SINO HOLDING GROUP is consist of SINO MOULD and Dakumar machinery .we are making customerized in mold label plastic parts as well as injection molding machine .

So far.SINO factory have So far , we have help customers who arenew in in mold label bucket or in mold containers .we help to establish theirplastic IML pail plant for more than 100 turnkey projects .

including paintbucket with IML system. Food container package line . table and chair moldingline ,Automotive parts production line .etc .

Our company have rich experience in assisting you establish your IML bucket production line from zero .

For example .For the plastic IML paint bucket molding line .We can offeryou with

-IML bucketmolding budget analysis .

-All IML moldingequipments .such as customized IML mould .suitable IML bucket molding injectionmachine .in mold label robot system.all necessary auxiliary machines .

-Plant drawing .like your plant water/air/electrial design and lay out.

If you haveexperience in in mold label bucket or container .or without any experience,welcome to contact us for more information about your new IML projects . wewill offer you the whole turnkey production line .

Contact :Selinda

Mail:export@sinomould.com

Whatsapp:008615858629913

Sino Mould Co., Ltd has rich experience in plastic field, and it is one of the most famous automotive parts mould manufacturer located in the southeast of china.

Sino Mould have continued to develop various plastic injection moulds, such like bumper mould, grille mould, fender protactor mould, shock absorber mould, instrument panel mould, door trim mould,column cover mould, lateral dash board mould. We offer the best quality mould with prompt delivery and service.

Sino Automotive has strong management for the quality and order control. We have nearly 40 designers to analyse and design the mould.The softwear we use is UG, Pro-E, Catia.Project department, processing department and quality control department will devote in the whole order precessing control. Our in-house high precision tooling center include 5 axis high speed CNC, Sodic EDM and wire cutting, CNC engraving, CNC milling deep hole drilling, they can tool the large parts and guarantee the dimension tolerance in 0.02mm.

We have developed market for OEM and after-sales market for brand as BENZ, HONDA, NISSAN, TOYOTA, Peugeot, Hyundai and so on. If you are looking for automotive parts mould manufacturer, Sino Mould is your good choice.

Shelly.Lu

Skype:dakumar_machinery

Email:export@sinomould.com

Web:http://www.sinomould.com

With the changes in people's life styles, more and more foreign bars, restaurants and other occasions trends in the use of plastic chairs. The advantages of plastic chairs are cheap, lighter than wooden chair, easy to carry, durable, can stack and save space. So the market of plastic chairs show a rising trend.

Sino Mould offer various kinds of injection chair mould, such like fold chair, gas-assisted chair, dinner chair, art chair, children chair, bus chair, arm chair mould, armless chair mould, etc. What’s more, we have our own equipment for gas-assisted chair mould injection line and plastic molding machines. A good chair mold is according to a factory technology and equipment. Excellent technology, well equipment, made a good quality mould. We produced chair mould for more than 10 years, so we have rich experience in manufacturing chair mould.

Please feel free to contact us when you need any chair moulds or when you need chair production line. We are not only offer a chair mold or machine, but also a fine solution, Turnkey project and factorybuilding.

Posted by: stacy

Email: export@sinomould.com

Skype: sinogroupe-62

SINO Mould is a professional thinwall food container mould manufacture. With application of IML thin-wall food container mould and IML molding technology. SINO yearly makes 200 sets of thin-wall food container moulds. The thin- wall food container with many shapes: round, oval, square, rectangle, etc. We could offer the thin-wall food box mouldin a short time but guarantee the quality.Besides,our thin-wall injection mould can be set up on most high speed injection machines. What’s more, the thin-wall injection mould can be two cavity, four cavity and even more, according to different customer’s requirement.

With over 10 years of moulding building experience for the packaging industry, SINO has not only progressed with the technological demands, but has met new demands head on.

Please feel free to contact us when you need any thin-wall injection moulds or when you need high speed thin- wall injection mould solutions. We are pleased to welcome you to visit our company and know well our strong ability and good quality with service.

Postedby: Lily

E-mail:export@sinomould.com

Whatsapp/tel:+8615905869677

Skype:sinogroup -59

Sino has rich experience in offering complete PET preform and cap

productionlinefor you. We have provided many production line, such

as 5 gallon PET preform and cap production line, 72 cavities preform

and cap production line and so on. We could tailor-made the best

solution according to your actual requirements.

To make a bottle with cap, you need make PET preform and cap, and

blow the preform into bottle by blowing machine. Making PET preform

and cap all use injection molding machine, we suggest to use one

injection machine to produce preform, one injection machine to produce

cap. Because for preform, it usually transparent or add transparent blue

color, but cap isn’t transparent, if use one injection machine, it need take

a long time to changing the material and also will waste the raw material.

5 gallon PET preform and 5 gallon cap as well, 5 gallon PET preform

usually will add transparent blue toner, but 5 gallon cap will use

non-transparent color masterbatch.

As per your productivity, we will recommend the suitable machine and

mould cavity for you.For 5 gallon PET preform mould, it can be made

into 1 cavity or 2 cavities.

1 cavities 5gallon PET preform mould

Cycle time: around100-110 seconds

Suitable machine:Dakumar 350Ton(Or 450Ton) PET injection machine.

Preform height affect the machine size.

2 cavities 5gallon PET preform mould

Cycle time: around120-130 seconds

Suitable machine:Dakumar 650Ton PET injection machine

It can use robotto pick preform out of the machine which is very

convenience when production.5 gallon cap mouldcan be made into 8

cavities, 16 cavities, 32 cavities…

Most customers like16 cavities 5 gallon cap mould.

If you are interested in setting a 5 gallon PET preform and cap

production line or other bottle production line, please kindly contact me.

Posted by Erin

Email: export@sinomould.com

Skype:sinomould-10

Whatsapp: 008613616760952

Electrical parts, one of plastic partstrade usually ignored by us, but it still have a certain proportion in plasticinjection trade. As these parts, we will take mind of the power bank shell, theair-conditional controller shell, some switch shell and so on.

As a professional plastic injection molding solution expert, we already made lots of electrical parts mold, such as powerbank shell, air-conditional shell and so on during our plastic injection molding career from 2000. The main market for the electrical parts is Brazil,Italy, North America and so on.

For our experience, when we made the electricalparts, we need pay more attention for the products dimension. Because suchproducts have high requirement about assembling. If the products can not assemblewell, it will be useless for our clients.

On the other hand, the electrical partsshould have a stripper angle for stripping, otherwise it is easy to hurt duringstripping. And pay more attention about the structure is very necessary, likeundercut, hole in the products.

If you have any interest for our plasticinjection molding solution ,welcome to contact. You could contact me withbellow mail!

Welcome to visiting our company for furtherdiscussion.

Snow

export@sinomould.com

Sino is a professional and world famous plastic medical high precision mold manufacturer. In recent years, in the field of high-precision mold, such as medical treatment, sino also has been a major breakthrough in the industry respected, the object of worship.

In the medical field of high precision molds, Sino has its own professional produced ideas. Such as medical needle mould, injection mould is a precision, products need to contact with body, so the product inspection requirements are very strict, if you don't have rich experience in it , its difficult for people to do a good job really, there is a great probability to be scrapped.

First of all, the selection of mold steel, mold is suggested to choose a high hardness, HRC35 degrees above the steel material is the most appropriate, generally you can choose nak80/S136 steel. The heat distortion of the mould is small, and the discharge is good. Secondly, the control precision is very important, because the puncture needle products is very small, the smallest hole size is only 1mm in diameter, but also have to ensure the concentricity of the core, this is a test of mold processing and processing of the precision of equipment. We choose the processing equipment used in the import of high-speed lathe. As far as possible to choose the equipment for less than 5 years, because the number of equipment years has been the actual machining accuracy has deviated from the direct impact on the formation of products. The needle to use copper electrode is not easy to wear, high-speed carved in place after the die and then hit the mirror EDM in place (it should be noted here that spark gap control).

Third: the glue outlet choice, this product will generally choose the design structure of multi cavity mold, hot runner to latent imported glue, glue for export on slope, it is prone to pull the gum of the mouth, this time latent EDM adhesive is particularly important, as far as possible in the spark gap is less than 0.01.

Finally, with the needle cap assembly, needle cap relative to the needle is still relatively simple, not too high detection standards, as long as the needle can be matched with the.

If you are looking for a medical high precision mold manufacturer , please feel free to contact us, we won't let you down.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Unscrewing cap mold, one of the usualplastic injection molding caps, the molding is a complex technology comparedwith other caps molding. But this is one of our characteristic developingproject.

As a professional plastic cap moldingsupplier, we export around 500 molds around a year, including oil cap mold,unscrewing cap mold, water cap mold, 5 gallon cap mold and so on. As we allknow, the cap mold is important in accurate tooling. Such mold have highdimension requirement for its assembling.

As usual, our mold material is S136 for thecore and cavity. With professional cap closure design, we will offer a fullyautomatic unscrewing solution for your deep screw. The most cavity number wemade for clients is 120 cavities. We also design with optimal cooling systemfor high speed injection. Best neck fitting with preform during our design.

Trust us, we will made a perfect solutionfor your packing project. If you have any interest about our package solution,please feel free to let me know.

By the way, we not only have plasticinjection mold, also have plastic injection molding machine with assesories. Wecan develop a money printer for clients starting from zero.

Waiting for your contact!

Snow

export@sinomould.com

Foldable crate plays an important role in our life.Foldable crate is widely used in machinery, automobile, home appliances, light industry,electronics and other industries, Its reasonable design, excellent quality are suitable for the logistics of the factory transport, distribution, storage, circulation etc.

SINO Mould is the world famous foldable crate innovatorand professional foldable crate manufacturer.Thereare A series foldable crate, B series folding container, C series collapsible crate, and D series large folding container. Foldable crate A and B series aremade by PP+ HDPE, it has light weight and long using life.