Thin wall molding is actually defined as molding the parts having wall thickness 1 mm or less than that. Speed plays most important role for the high profit in the field of thin wall injection molding. Faster filling and higher pressures are required to drive molten thermoplastic material into thinner cavities at a sufficient rate to prevent freeze off. For this machine equipped with accumulator to realize high speed injection and single cylinder injection system, especially suitable for high speed injection, with low inertia and high response speed is required.

SINO HOLDINGS GROUP is extensively experience in the field of thin walled injection molding and has manufactured super advanced mold and molding machine involving to meet the match today and beyond. Our high speed machine can reach 2.5 sec of cycle time to produce 4 cavity thin wall box of 0.4 mm wall thickness. Not only mold and machine we offer whole production line in cost effective way.

But the fact is, thin wall molding is very difficult to deal with.Much many thing are to be considered while designing tool for thin walled injection molding.

1: To withstand high injection pressures gate inserts of hardness greater than 55 are typically used .

2: Manifolds should have external, not internal, heaters. Valve gates, if used, must be non-restrictive and built to take high pressure.

3: Venting is critical and can be facilitated with vented core pins and ejector pins,While not usually necessary, some processors have sealed the parting line with an O-ring in order to pull a vacuum on the cavity for quick gas evacuation.

4: Nonlooping cooling lines should usually be located directly in the core and cavity blocks to help keep the mold surface temperature as consistent as possible.

5:When gating directly onto a thin wall with a sprue, pinpoint, or hot-drop, use gate wells to reduce stress at the gate, aid filling, and reduce part damage when degating.

6: The mold cooling system design must be optimized so that heat is extracted quickly. Just having thin walls on a part is not enough to get fast cycle times.

7:Any build up of residue across the venting surfaces will result in part quality issues especially on multi cavity moulds.

Rahul shah

email: export@sinomould.com

skype: sinomould-15

whatsapp: 008613989381153

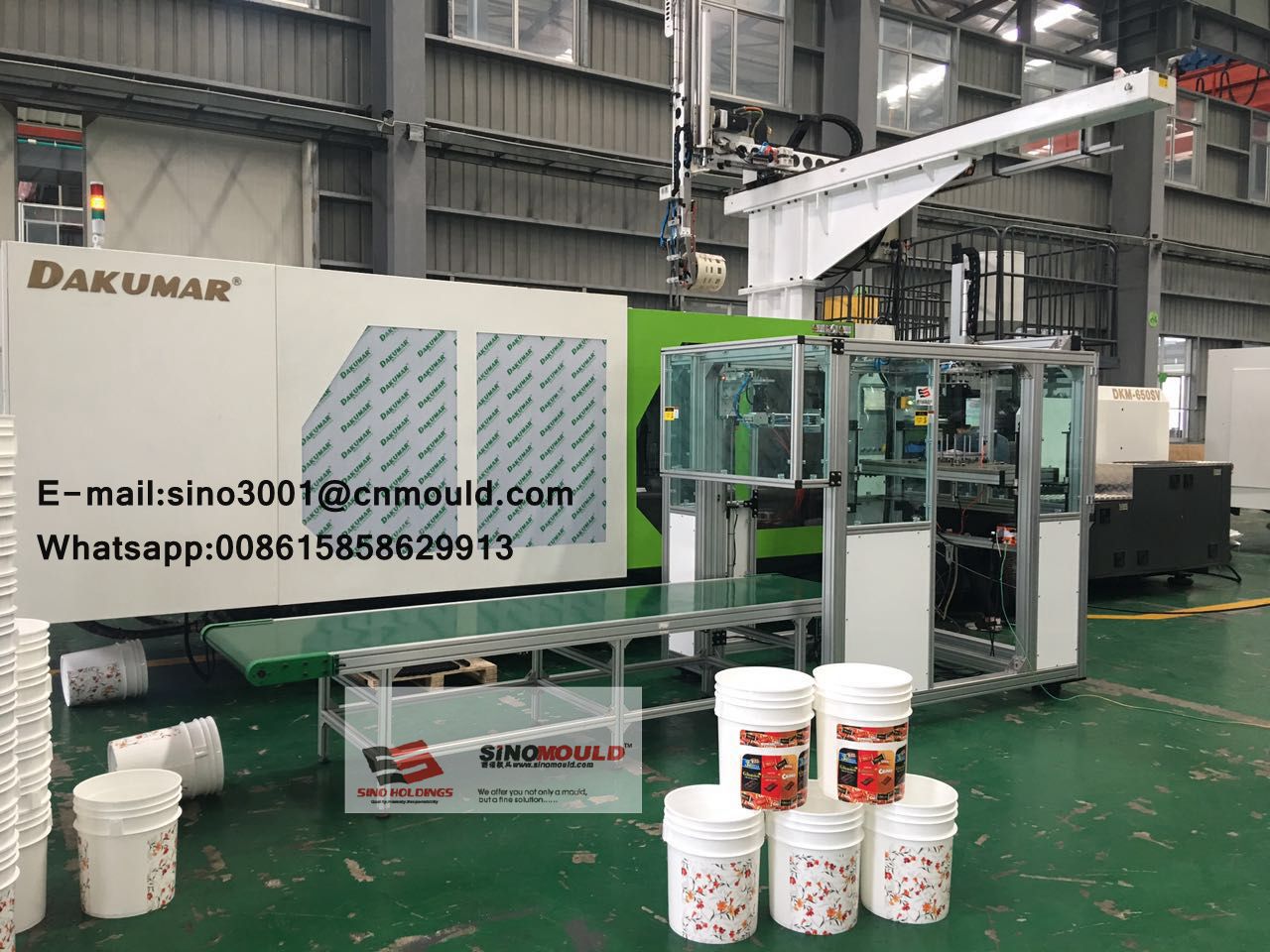

5 gallon paint bucket or 5 gallon lubricantbucket are usually used for painting or lubricant oil package, as an consumedbucket or container , there are big demanding for the 5 gallon industrial pailevery year . so there are more plastic plant focus on building plant forproducing 5 gallon bucket mould .

Sino Holding Groupe . as a well know brandin China ,located in the new mould town . consists of SINO MOULD and DakumarMachinery . so we are aimed at offering customer the turnkey project for theirindustrial pail plant set up .help customer establish plant according theirinvestment. we have rich experience in offering customer the turnkey productionline . actually ,we have made more than 20 turnkey insturial pail plant set upfor our customer according to their requirement . take a 5 gallon bucket mould industrial pail plant set up we made for our customer for example .

What we offer : Firstly ,5 gallon bucketmould , 5 gallon bucket lid mould ,5 gallon bucket handle .

Secondly : Suitable machine ,we use DKM650for the 5 gallon bucket production line set up .

Thirdly : We will test the mould andmachine on our Dakumar machine until it smooth ,and can send engineer to customer plant .

If you have any new project about 5 gallonbucket mould and industrial pail plant production line . welcome to contact usfor more information .

E-mail :export@sinomould.com

Skype:sinogroupe-selinda

Whatsapp:008615858629913

Plastic flip top caps are widely used in health and beauty, pharmaceutical and drinking, leisure and automotive area. And with enlargement demand, flip top cap mold becomes more popular.

We have been providing and exporting shampoo flip top cap mould, toothbrush closure mold, drinking bottle cap tool and others at least about 20 years. And our cap experience become mature and got high reputation among customers.

The characteristic of our flip top cap moldis unscrewing system, auto-close system and interchangeable inserts for pins.

1.Unscrewing system. One ishydraulic cylinder power, the other is motor pull gear to finish unscrewing.

Accord customer flip top cap structure and requirement, we will design best one. Besides,unscrewing system will run smooth and easy for maintenance.

2.Auto-close system/insideclothing system. Our design for auto-close is welcome among customer as this systemis strong and close top cap totally. Besides, this system is easy for installing and take off. We also will show this video and teach customer how to operate.

3.Interchangeable inserts. Fliptop cap had a comprehensive range of size. To meet this, we could provide interchangeable inserts for pins. And for easy operation, this inserts couldchange in front of mold.

If you are looking for cap mold supplier, pls feel free to contact us.

From: Stacy

Email: export@sinomould.com

Skype: sinogroupe-62

Whatsapp:+8615168642559

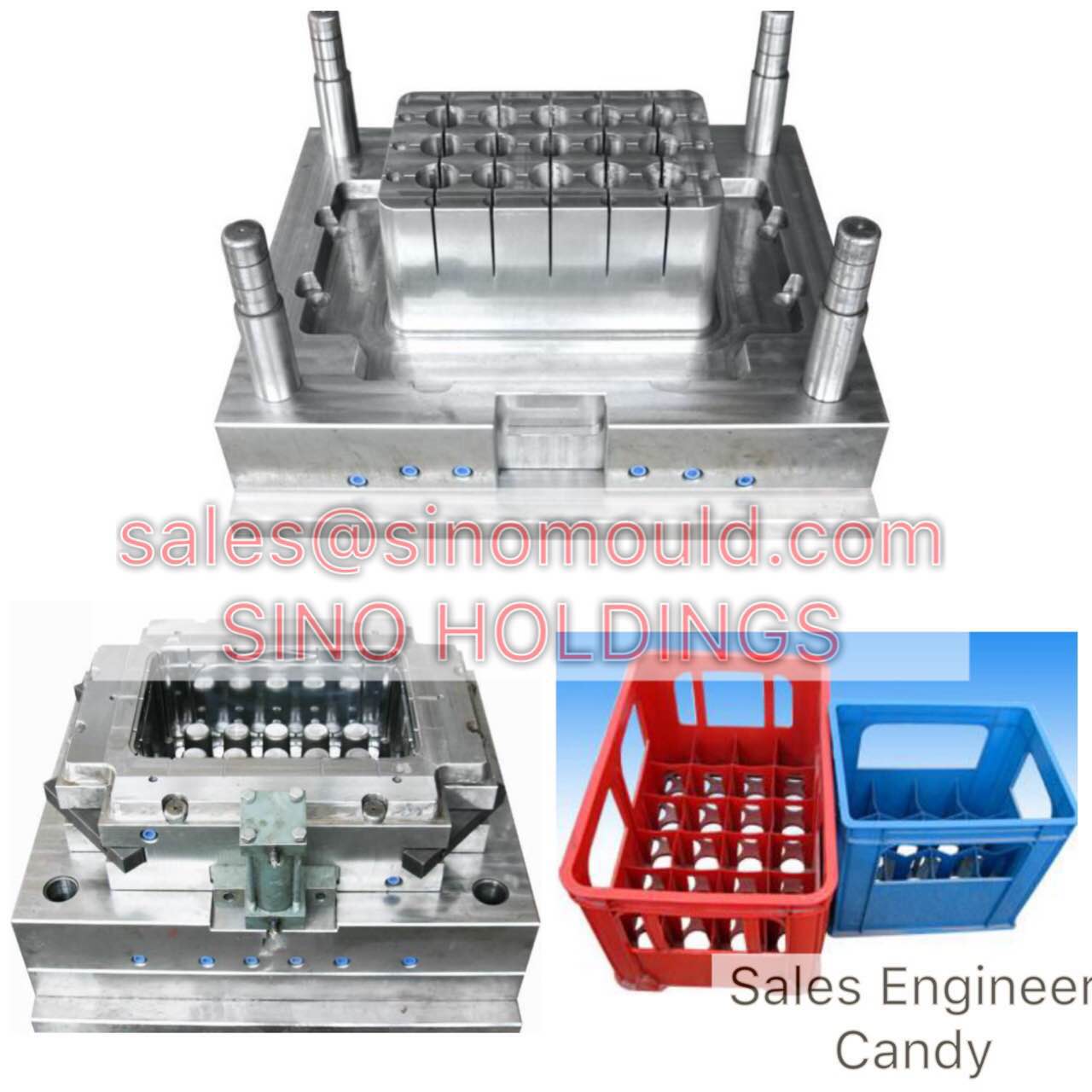

Plastic crates are too much popular all over the world, crates mould also included 24 bottles beer case mold. Beer case is widely used in supermarket, beer and soft drink storage and distribution. It Worked with pallet will much more convenient. In addition, plastic beer box mould design based on Ergonomic principles makes Manual handling easier.

24 bottles beer case mould special design separated each glass beer bottles, to prevent the collision and the longevity of the beer bottles breakage effectively. The advantages of beer crates:

1. Made by plastic material, has light weight and longer working life.

2. Plastic material is recycling, reduce waste.

3. Protect beer very well

4. Stackable to save space and convenient transportation.

5. Recycle plastic material has low cost.

As is known to all, crate of beers have division plate inside, this part has the character of thin wall, hard to injection and flow completely. So when we make beer case design or mold, we should consider the production flowing structure very carefully, make mold flow in details. Special mould structure and hot runner technology will help benefit the product appearance and shorter cycle time.

Sino vision: being the world famous supplier for Turnkey injection molding line with service, technology solution and equipments. If you are looking for China 24 bottles beer case mold maker. Contact Candy freely.

email: export@sinomould.com

Fan Blade mould, which designed for electrical fans, air conditioning industries like cassette air conditioners, air purifier, air ventors, evaporative fans....There are many types of fan blade molds, with different functions, different types and different materials, but all the fan blade need to pass balancing testing and noisy veritification.

With over 20 year molds tooling experience, Sino Mould can design and manufacture all kinds of fan blademoulds, and we are long term mold partner for air conditioning industries, air cooling devices manufacturers, like Gree, Midea, York.. Many famous home appliance makers who need to buy the fan blade molds.

How to make sure that the fan balance mold with balance injection?

The key point for the fan blade mold is the very even injection gates and equal thickness. Injection runner design, cooling water design and moldflow analysis play vital roles in fan molds manufacturing, also the mold temperature controlling are very important. Like the table fan blade mould, 16 inch diameter, fan weight around 150 gram, three blades mould, we will design one tip hot runner nozzle with three injection points instead of direct core on the center of fan, the fan centre location will be inserted with cooper for for short cycle time, 6 groups of water channels with 3 groups of water channels followed the fan shape. Injection sprue bush is DME standard with cooling water around. And when we test the mold, the mold linked with cold water with 10 degree. The total cycle time is 35s, with plastic shaft inserts and the unbalancing weight is less than 0.4 gram.

Sino Mould is specialized in all kinds of fan blade moulds, the material of fans can be PP, ABS, AS+25%GF, PA 6+25%GF, the mold steel for core and cavity can be S136, NAK80, DIN.12738, DIN.12344 according to the fan's material and fan's applications. If you need fan molds or want to know more about fan molds, welcome ton contact us.

Ms Joyce

Sino Holdings Group Co.,ltd

Sino Mould Co.,Ltd /DAKUMAR Machinery Co.,Ltd

Email: export@sinomould.com

Skype: sinomould-11 Wechat/Whatsapp: 008615257607361

These days trend of using plastic furniture has been increased rapidly . Plastic furniture has been able to take big market success. Plastic furnituresare light weight , durable, water proof ,easy to transport, cheap to buy , beautiful and can be made in various color and design, mostly used in catering, garden , home and offices .Due to which plastic chair has become one of the most important furniture and key point for business investment.

SINO MOULD is leading mould manufacturing company in china and we have professional team of engineers for plastic chair mould design and melt flow analysis .We annually produce 300 sets of plastic chair mold which includes Gas assistant chair mould, PC transparent chair mould, Arm chair mould, Armless chair mould, Rattan chair mould,High back chair mould,Relax chair mould,folding beach chair mold, sofa mould ,Table mould,Round table mould,Rectangular table mould, Square table mould, Stool mould, Baby stool mould , Kids table mould , Child table mould , Baby chair mould and also chair mould with back insert changeable design for different versions and different seat insert.

Considering mold cost and customer investment P20 steel is mostly used in core and cavity however 718 steel is very good steel for high quality and mirror polish of the core and cavity. These mould requires high polishing, mold flow analysis and proper venting. Steel hardness play vital role in mold longevity ,avoid flashes at the ends and sides of the product and also avoid other kind of defects in mould.

High care should be taken while assembling chair mold , precise inspection of the all parts including cooling systems, hydraulic oil channel system ,hot runner , mould plate, ejector pin, stripper, ejector block or slidersystem should be done. Interchangeable back rest inserts helps to get new chair design.

Demand of fashionable and unique design of plastic furniture is increasing day by day. SINO MOULD can provide complete and cost effective solution regarding plastic chair mold of any kinds of customer’s own unique design conveniently.

Rahul shah

export@sinomould.com

008618358681772

skype- sinomould-15

Sino Mould is a professional plastic bucketmold manufacturer, we can provide you the best quality and price, can offer youplastic injection mold.

SINO is a well-known supplier all over theworld by various kinds of plastic molds manufacturing. Sino has more than 20years of experience in the creation of all kinds of plastic shapes. Especiallythe bucket mold, it is one of our mostimportant plastic injection mold. And our mold bucket including a bucket ofwater mold, paint bucket, fishing bucket mold, packing bucket mold, mold buckettrash and other forms of bucket, we have a high ability to produce a bucketforms you and always aiming to be the best china bucket mold company.

For our bucket mold , we always supplycustomer to select the plastic materialby PP. HDPE. And usually, we suggest customer to select the steel material 2738(HRC35-38), (HRC35-38), 2311, P20.

Sino has a professional independent design team: more than ten years experience in molddesign. We can design various kinds of bucket mold according to your idea orphoto to meet your needs which you want , We are also welcome to receive yoursamples and we can ensure our mold will be the same with your samples.

Usually, for small bucket, we suggest you touse hot runner point gate.

For big bucket, we can offer you to hotrunner big gate,

For extra large bucket ,we suggest to selecthot runner with multiple gates.

Sino offer you the perfect service system: wecan provide replacement parts free of charge within one year. Provide universalsolutions to any problems occurred in customers' mold supports operationsthroughout life.

If you are interested in our bucket mold, if you are searching for good quality bucket mouldmaker, please contact me, SINO is a good Plastic Bucket mold manufacturer.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

SINO MOULD is a good medical mould maker.For testing tube mould, we have mature experience in making 16 cavity PSmaterial testing tube mould and PET material testing tube mould. Now ourR&D department is working on 32 cavity PET testing tube mould.

For 16 cavity PS meterial testing tubemould specification:

1) Mould core and cavity steel will useStavax Esr (S-136),made in ASSAB, tempered with HRC45-48

2) Mould base: P20

3)Mould size:400x360x350m

4) Suitable Machine tonnage:DKM180 TON

5) The cycle time is around 8 to 10 seconds

6) Hot runner: Anole pin point gate system

7) Mould delivery time: 60 working days.

Mould difficulty:

The testing tube mold core inserts are verythin and long, that makes it easy deformation under high speed and highpressure injection. The tooling concentricity and precision control isextremely important. Also the assembling should be in very correct position.0.1mm mould tolarance would make product thickness tolarance over 0.7mm.Thenormal tolarance should be around 0.1mm. Like thin wall mould, testing tubemould also is a one time successful mould. If it faild, we need to purchase newcore inserts and re-tooling them. For testing tube mould, you should give theorder to professional testing tube mould maker like SINO MOULD.

Welcome to contact me if you have testingtube mould project.

Whatsapp: 0086 15958616791

Email: export@sinomould.com

With mature technology for thin wall containers molding, customers enjoy our high efficiency airline cup molds, PS thin wall cup molds, disposable airline cup molds ect.. They are from America, Brazil, Russia, Turkey, UAE, Egypt and so on.

According to experience, we understand well mold main points for top quality airline cup mold. We apply self locking structure (one cavity one block) for multi-cavity mold to ensure precision dimension tolerance and cup wall thickness uniformity. While, it’s easier for mold future maintenance and save your cost. Our 4-cavity PS cup mold realize 5 second cycle time, for optimal cooling design , Anole valve gate and Dakumar high speed injection machine DKM200HH.

Like our tailor made PS airline cup mold to customer who is one biggest plastic food container suppliers in America market. For this mold, we applied S136 mold steel , tempered with HRC 45-48 to ensure long mould life. At same time, it’s matching to PS transparent cup requirement and high speed running molds.

SINO has strong ability to support high injection performance disposable airline cup mold with our innovative team and advanced equipment. Warmly welcome your contact and visit with your project details.

Posted by Ms. Helen

Email: export@sinomould.com

Skype: sino.group10

Cell phone: 0086 15858625783 (Whatsapp /Wechat/ Line)

Now crates are more and more widely used all over the world, such as vegetable crate and transport crate. With this huge demand, crate producer needs to a reliable crate mold supplier.

SINO MOULD is the leader crate mold manufacture in China. Every year our mold output quantity increase year by year. As a professional supplier, SINO offer plastic crate mold for different countries.

Our crate mold is good quality and mold design. Before the mold ismade, our designer will analyze the mold and improve the success rate of moldmaking, to ensure product quality. We use hot runner technology, it can optimize the mold structure and save the molding cycle time.

Mold in the processing design has the following characteristics:

1.Fast cooling time, short cycletime

2.Reduce the mold and production costs

3.Improve the materialutilization

4.Mold structure is compact, flexible movement

Before shipment, we will arrange test mold to ensure that the moldquality, then we will send you samples to check. If any problems with mold, we can service at any time.

If you are interested, pls feel free to contact us. Thank you for your support.

Post by Vicky

Email: export@sinomould.com

Whatsapp: 008615905869677

SINO Mould is a professional mold manufacturer in designing and making plastic PCchair mould. We produce around 150 sets chair molds for one year, including PC transparent plastic chair mold, plastic rattan chair mould, PP chair mould and so on. With accumulation of so many years of PC chair mould production, now SINO has a mature technology and experience.

During the daily production, below is some issues required special attentionfor plastic PC chair mould:

1. Product scratch

PC material is very hard. if the mould steel hardness is not high enough; it will be easy to have the scratch problem. So usually for PC chair need good steel with high hardness and could also make nitriding on the mould surface which can increase the surface hardness to avoid the scratch problem.

2. Not good transparency

Mostly the PC chair mould will use transparent color, but I believe many people have met the feedback from the customer of complaining about the transparency. You can choose oil temperature instead the water temperature which can better solve the problem.

3. Silver mark on product

If the product surface has the silver problem, it means that the material is not dried enough, mostly it needs around 6-8 hours to make it dryer at around 100 degree temperature

4. Cycle time

Some customers need short cycle time, but as you know for the plastic PC chair mould, the thickness is thicker comparing to the normal chair, so the cycle time is longer than usual chair. And you can make the gate size bigger for easy material flowing.

.

.

If you are looking for the plastic PC chair mould, pls come to us for further information.

Welcome inquiry!

Martina

Skype: sinomould-17

Email: export@sinomould.com

Mobile/We chat/whatsapp: 0086+15215807221

Sino Holdings group is outstanding in supplying plastic turnkey molding productions lines, we aims to offer famous turnkey molding lines and service for our customerin china. with rich experience accumulated, we are more and more professionalto make high quality lines with prompt delivery. At my hands, new plastic tapa/cap molding line is finished. It is offered for our south America customers.

For plastic tapa molds, it is made for dimension 47.5 cap with sliders structure on capanti theft rings area. Mold main steel is stainless steel with 2316 tempered at HRC2-45. Tapa mold is made with 32 cavities with full hot runners, each tip controlson cavity with point gate. And in order to make cap out surface with customer logos for different end customers, we support to make with cavity and cavity plates interchangeable on machines. Compared to change only cavities, it is more easier for customer to change, no need to consider hot runner tips during changing and assembling proves.

In orderto suit this 32 cav tapa molds, we suggest to use our DKM520 servo motor machines for whole lines running, also equipped with normal auxiliary machines.With whole molding lines, we make mass production simulation with 15s at sinosite. If you are looking for plastic cap molds and machines, welcome to contact with us.

Ms Diana

Mail: export@sinomould.com

Skype:sino.group01

Wechat/whatsapp:0086 13757677056