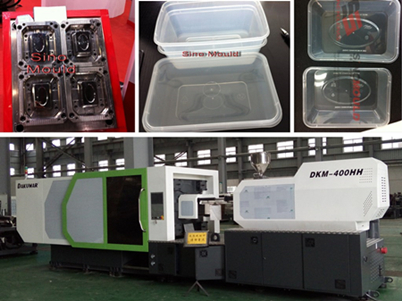

Offer plastic injection molding devices, plastic injection molding equipments turnkey project service by Sino Mould combined with Dakumar Injection Machineries.Turnkey project plastic injection molding machine,Plastic Injection Molding Equipment Turnkey Project Service,Turnkey Project for plastic injection molding factory building.

Plastic injection molding machine with plastic injection molds and other auxiliary equipments, these are the neccessory plastic molding equipments which are needed when you establish one plastic injection molding factories.

We are not only offer you the equipments, molds or tools, we also offer you the workshop design, machines and molds installation and workers training.

if you want to establish a plastic facotry, please come to us for turnkey project offering. It help you start your project in the shortest time, avoid your too much headache, wastage of time and material, also avoid your investment a lot with very lower reward.

Click this link for details of injection molding machines.

Plastic factory building, offer plastic factory building service, Dakumar Machinery Co. Offers the plastic factory building service for customer who want to establish a new plastic factory.

Please contact to Miss Nancy

export@sinomould.com

export@sinomould.com

Skype: sinogroup-nancy

Usually, A set of water filter should be considering the good sealingand high pressure test, so the assembly and part thickness must be according todrawing, to controlling the part in tolerance, our water filter moulds by high precisiontooling machine, and each step with Q.C to sure each part in right dimensions.

And for choose suitable mould material for water filter also important, forexample, filter housing plastic material is SAN or AS, so that mould materialshould be stainless steel, such as 2316, s136 it will be ensure part surfacequality and also mould life. Also for water filter cover with unscrewing design,sino have very good design idea and experience to avoid future mould problem.

After mould ready, Sino Mould will make simulation production at least 4hours,to confirm mould running smooth and everything no problem, we have made many waterfilter moulds to Ukraine, Russian before, If you are finding water filter mould manufacturer in China, We sure you will be satisfiedwith our water filter mould quality.

Email: export@sinomould.com

What's up: 86 15858625783

In China, have many good brand supplier forinjection molding machine, but as a one-stop service supplier Sino Holdings areChina bumper injection molding machine supplier and also bumper moulds supplier.

Sino Holdings combine Dakumar Machine andSino mould to study plastic bumper injection molding technology many years, andnow we have many experience on bumper injection molding.

Many auto bumper factory are fast-growing from difference model updated, they enlargefactory or building new bumper factory, because we have Sino Mould company,that we know well about plastic bumper mould detail, bumper injection molding work pointsand how to setting the parameter to control plastic bumper quality. It is big advantagesof Sino holdings to R&D injection molding machine. We have worked for manybumper factory from OEM and after-sales market, due to we have good experiencefor bumper injection molding machine, and Sino considering very good after servicefor installation, training customer, so that many customer want set up factory they come to us for bumperinjection molding line equipments,

Sino Team are very energetic and curiousinvestigators. Recently we are R&D two platen injection machine above 1000Tand 4600Ton big injection, it will be prominent performance compare with other China injection machine suppliers.

We are looking forward to provider good servicefor you if you are looking for plastic bumper injection molding machinesupplier from China.

Email: export@sinomould.com

What’s up: 0086 15858625783

SINO are manufacturer and supplierof spoon moulds and injection molding machine for spoon production,we arespecialized in making all kinds of disposable spoon mould, forks mould,knifemould. almost all types of cutlery moulds ,we can design and make according tothe customer original sample,or we can modify the design according to customerrequirement . we have offered many high quality, durability spoon mould for ourcustomers .We manufacture our products utilizing tested raw material and modernmachines. These raw materials are mostly PP,PS . We are spoon mould maker with rich experience .

Take our 24 cavity spoon mould forexample

Mould dimension :550 x 550 x 450mm .

Cycle time :15 seconds

Runner : 1tip hot runner or cold runner are both available.

Mould life time : at least 1 million shots ,so if 24cavity , the spoon mould can produce 24*1million pcs.

Suitable injection machine :DKM268Ton .

We can offer spoon mould , as well as injection molding machine for the specialized spoon mould .what is more ,we can offer the whole necessary auxiliarymachineries for the spoon production line . welcome to contact me for your newspoon project for more information .

E-mail :export@sinomould.com

Whatsapp:008615858629913

China injection molding line manufacturerSino Holdings Group we can helping customer to set up PVC pipe fittings moldingfactory. We supplying plastic pipe fittings moulds, injection molding machineand auxiliary equipments for injection molding line.

Many customer have idea for set up aplastic factory, regarding pipe fittings factory should be considering below requirements before factory set up:

1)What’s the model&size ofyour target PVC pipe fittings;

2)Target quantity of your PVCpipe fittings per month or year;

3)To know how machine injectionmolding machine and auxiliary equipments ;

4)Factory layout;

5)Factory circuit diagram, oil,air, water design diagram

Sino Holdings have different branch companyfor different area of injection molding line, including plastic mould manufacturer,injection machine manufacturer and other auxiliary equipments supply, to reducecustomer time to find different supplier. about PVC pipe fittings project, wehave made UPVC,PVC,PPR,PE material for different countries, such as SaudiArabia, Dubai, Jordan, Turkey, Russian etc…we have good experience on set up PVCpipe fittings molding factory, to considering PVC fittings mould have manyspecial construction, so the injection machine will be customized for customermoulds, except PVC screw, the machine for PVC size will be bigger than commonmachine.

We are very pleasure to teach you if youhave any idea to set up PVC pipe fittings factory, please do not hesitate tocontact me: Email: export@sinomould.com

What’s up: 0086 15858625783

Air conditioner molds making company,Sino Mould Co.,Ltd, who is a world famous home appliance molds manufacturer and exporter, with 25 years plastic molds processing experience.We have made split mounted air conditioner molds, cassette air conditioner molds,air conditioner blower fan molds for different models of 9000btu,12000btu,18000btu,24000btu... Who is plastic home appliance mold research and development center for YORK,TRANE(HAVELLS), Godrej, Midea, AUX, CHIGO.

While, we have made so many air conditioner molds, we are well known how to design air conditioner molds in optimal condition. DMF analysis can be offered to provide suitable mold design and manufacturing solution, with accurate injection runner selection, reasonable air venting slugs setting and optimal mold configurations as per the air conditioners’ requirement and moldflow analysis report. Sino Mould will provide detail tooling procedures for each air conditioner molds with strict mold part dimensions controlling in the ISO 9001-2008 certified quality management system.

After the molds are finished machine processing,we will do the mold running simulation in our company to check the mold movements is smooth or not, parting line is clear or not, air venting system and water cooling system are optimal or not... Project manager will keep notes for the best injection data and tell customers what will pay more attention during production. We are sure that every air conditioner mold from us are qualified before delivery.

Sino Mould is professional air conditioner mold maker with advanced mold design philosophy high precision tooling machines and high-tech engineers for air conditioner molding technique. If you are finding high performance air conditioner molds in China with a optinal air conditioner molding solution, don’t hesitate to contact us!

Ms Joyce

Sino Holdings Group Co.,ltd

Sino Mould Co.,Ltd /DAKUMAR Machinery Co.,Ltd

Email: export@sinomould.com

Skype: sinomould-11 Wechat/Whatsapp: 008615257607361

Sino mould is one of the Chinese best chair mould manufacturer in China, has support more than 150sets plastic chair mould of various type ofmoulds for word wide market. We knows much about the euro market requirement.Combine the development mould quality standard and process machine, devote ourbest production experience and precision control. Welcome to make detailconsultation.

For the chair injection moulds,consider the mould cost and customer investment cost.P20 material is most usingfor the mould core and cavity material. When design the arm mould, Sino designdesign will measure all the size and weight of the original sample, make themould production analysis. Before production, will shows all the considerationof the future stacking and weight tolerance. And consider some venting systemand better forming. Some customer lack of injection molding machine choice andnew business for the chair molding production line, Sino group company willprovide the a series arm chair plastic turnkey molding solution productionline, we will help you equips with Chinese best injection molding machine-Dakumar with perfect molding line system. Dakumar is our branch companymainly supply the injection molding machine with Euro standard. Choose Sino,equals to earn the market. We will help you establish stable production lineand prompt technical support.

Please feel free to contactsino group. Arm chair molding line support, Sino mould will do our best

serve you well. export@sinomould.com

whatsapp:008615067608197

Sino mould has very strong ability in manufacturing large size industrial dust bin molds, such as 240L, 360L, 880L, and 1000L waste bin mold making. Together with our injection machine manufacturing advantages, we can offer you whole waste bin production lines, high quality and performance for you to get profit in shortest times.

With industrial dust bin molds, such as 1000L volume, during part design process, we would make detail mold flow analysis, with cooling system to check part injection filling time, deformations on final part, accurate clamping force need, and so on. Due to most industrial bin need durable using purpose, we would use low mold flow index material for filling, it would also increase the difficult for part fullfill process. In this way, it needs good designs to assist. And for 1000L dust bin molds, it is not only big size need large tooling machines, it is also important to have molds with accurate tooling on movement area, to avoid scratch or stuck during mold production process.

Usually according to our experience, for such size plastic dust bin molds, it needs around 4000ton at least injection machines to running. Our company has this tonnage machine for testing, also we make this machines for sales. So it is mo problem for you to have molds trials or purchase turnkey molding lines.

Welcome your down visiting to Sino holdings. If you have projects, pls do not hesitate to contact me.

Ms Diana

Mail: export@sinomould.com

Skype: sino.group01

Wechat/whatsapp: 0086 13757677056

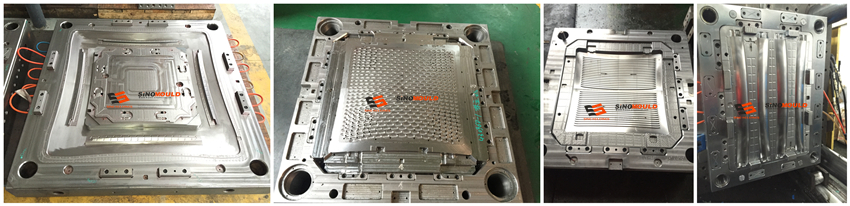

Sino Mould is a top plastic injection mould maker located in South East of China, we could supply high quality thin wall container mould with multi-cavity type, such as disposable food box mould, ice cream mould, paint bucket mould and so on. With our sister company Dakumar Machinery team work, we could supply high speed production line for disposable food box making.

For the disposable food box, it is one time using, then recycle and remolding. We design the box with the wall thickness within 0.5mm, for example, 0.3mm wall thickness for 200g container, 0.4mm wall thickness for 1L container, 0.45mm wall thickness for 2.25L container, etc.With thin wall thickness, the plastic container weight could be reduced, it could save much cost for the PP plastic raw material consuming and increase the production efficiency. We use high quality stainless steel material S136,DIN1.2316 for the container mould, it is suitable for high speed running with good polishing.

Attached is the picture with 4cavity disposable food box mould for 1L capacity, we make the mould for 4cavity 500ml container mould, 4cavity 750ml container mould, 6cavity 500ml container mould and other multi-cavity mould. We design the mould with good cooling system and with wear plate to adjust the flash or wall thickness balance. With high precision tooling machines, the thin wall container mould could run high speed and high stably for long time. Welcome to contact us formore information.

Post by Miss Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

SINO MOULD is a world famous high qualityplastic paint pail mould maker.

We offer perfect solution for differentvolume paint bucket moulding line. If you want to start paint pail production,you can contact us and visit our factory.

The rich experience makes SINO MOULD growup very fast in bucket mould making. Every challenge lay the foundation forfuture success. You much know the risks in the beginning. Sometimes the moulddevelop failure due to communication error. Customer didn’t tell their demandduring product design period, and find out problem after receive testingsamples, sometimes the mold makers doesn’t understand what customer meaning. InSINO MOULD, all the sales engineers are trained professional to paint pail moulds.They will lead the customer to given necessary information in the early period.Product design and mould design will send to customer for approve before cutthe steel. Even some modification needs at the end, we will try to offer bestsolution. All the careful work and responsible sprit helps SINO MOULD becomesthe famous high quality plastic paint pail mould manufacturer. Once you placethe order in our company, you will be treated with patience and kindness.

Don’t hesitate to contact us: export@sinomould.com

Add: 369# Xinjiang, Xinqian Street,Huangyan, Taizhou, Zhejiang, China P.C.:318020

The best service in Sino is the turnkey molding line building in the customer local, offer the one-stop service for the syringe needle cover molding line.Our service is consider all the demand for the needle cover production equipsand support moulds and machine ,provide the engineer training and after sales ervice. Help customer solve all the confusion and problem. Of course, likemedical parts so special production environment request, Our professional engineer team will help you build dust free with medical grade workshop. Equips technical expert teach you step by step.

If you are looking for medical parts injection molding line, welcome here make detail consultation to Sino holdings group. Sino holdings group company owns the most professional technical analysis and manufacture team. for the medical parts moulds, in order to ensure processprecision and match detail, Sino mould invested more than 15M USD for various precise tooling machines. Most of them are from Europe and Japan.

Sino holding group company, set into mould and machine more than 20 years. We can provide a turnkey molding solution forthe customer,one-stop service. Welcome make Syringe needle cover molding serviceenquiry detail, Sino mould will do our best serve you well.

whatsapp:008615067608197