Sino Mould is a professionl and experiencedplastic mold manufacturer. Such as plastic bucket mould ,thin wall box mould,pipe fitting mould, crate mould , plastic table mould, automobile parts mouldand so on. It is worth mentioning thatSino is also a Plastic chair mould makeralso.

For famous plastic chair mould maker, sinois based on providing customers the best quality solutions and service. We cancustomize the best one according to customer's requirements. Plastic chair moldhas been widely used in the world. Sino has produced more than 500 sets ofchair moulds for customers around the world. We also specialized in theproduction of air assisted transparent PC chair mold.

There are some basic technical points forthe chair mould as belows:

1.Production cycle time: around 40-50s

2.About the gate type: suggest to use semihot runner Side gate

3.For the steel and hardness: suggest touse P20 steel,and the hardness HRC33/ DIN 2738 steel,and the steelhardness HRC35-38.

4.Chair mold life: normally, the p20 steelis more than 500 thousand die, and the steel material DIN 2738, can use morethan 1 million mold

5.For flower board swaping: we can makeinsert block swapping, and offer more choice to you

6.Injection molding machine tonnageselection: we suggest you to select Dakumar self-produced servo machineDKM-SV780.

Inspection standard of Plastic chair mould:

1. Superimposed: after the chair shaped, weneed to check its superposition effect, stacking up verticality with 15-20 layerstack.

2.Weight: usually, it may be about 2.2kg,Ifoverweight, it will increase customers cost, reduce profit, if too light, itwill reduce the wall thickness, and the quality is not well.

3.Parting line: if the line is incisive, itis very dangerous, especially for children and women.

On the whole, sino is a professionalplastic chair mould maker, we have a huge team to avoid these questions. If yuoare looking for good chair mold manufacturer, please feel free to contact me.

Posted by: Rose

E-mail: export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

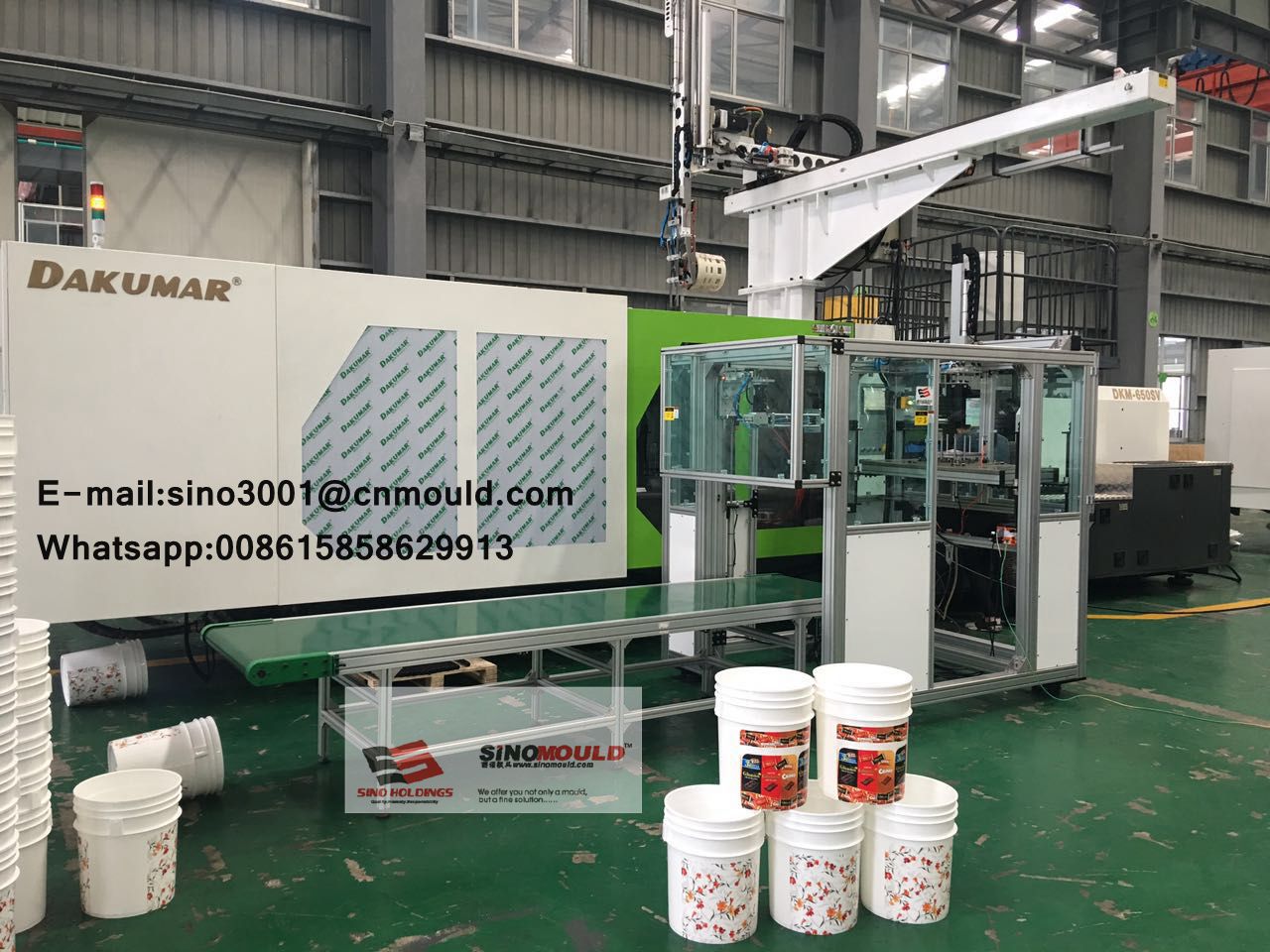

What is the cost for set up a plasticbucket factory? Have you checked the budget of setting up a bucket plant ,tostart a whole bucket production line.

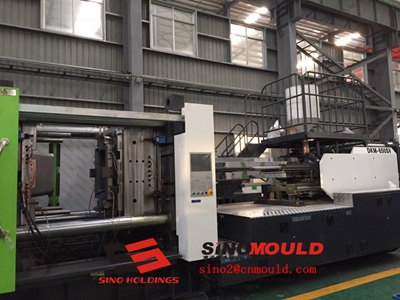

Sino Holding Groupe is the leading plasticmould and machine ,we are specialized in making all kinds of bucket mould ,rangefrom 1L /5L/10L,16L/18L/20L bucket mould .bucket lid mould . bucket handlemould . meanwhile ,we are offering the whole bucket production line .so if youare a new starter in our company .we will be your good choice for build your bucket new plant production line .

We can provide your service as below .

1)before you start you new plantbuilding , we can check and make a layout of plant for you .

2)we will recommend the mosteconomic solution for customer bucket plant build up according to customerbudget for new factory set up

3)we will suggest the suitableinjection molding machine according to customer’s bucket mould ,and choosesuitable auxiliary machineries. Such as water chiller ,auto loader ,dry hopper. mixer and so on .

4)we can send our engineer toyour new plastic factory to help advise and install the mould and machine,until it running smoothly .

we are professional in offering customerwith the complete bucket production line .we are good at offering bucket plantset up . if you have new bucket project to start . welcome to contact me formore information .

E-mail:export@sinomould.com

Skype:sinogroupe-selinda

Whatsapp:008615858629913

We have mature technology in manufacturing various kinds of auto wheel cover production lines, and we have the ability to develop the new designs. The whole molding line includes auto wheel cover mold, injection molding machine, necessary auxiliaries with favorable price, such as water chiller, auto loader, hopper dryer and robot etc.

At the beginning, customer can offer product drawing or samples to us and tell us their requirements, then our quotation department and sales engineer will check all the points that offered by customer to figure out the cost and make list of the necessary equipment.

Once the customer confirms the order, Sino will support the customer with factory layout plan and factory design requirements,which will help customer save time. At the same time, Sino will start mold and equipment making, and offer progress report weekly.

When the mold and machine are ready, then we will set up the whole line in our company to realize mass production,usually we will test at least one day to make sure the whole production linecan run smoothly. If everything goes well, then we will ship out the wholeline.

When all the goods are reached customer’s factory, Sino will arrange our engineer or agent to customer’s factory to do installation and commission. What’s more, Sino also can offer the all round molding factory equipment training and management training. All these are our advantages to support customer with our ability and complete service for their new plastic molding factory set up. If you want to set up auto wheel cover molding factory, welcome to contact me, Iam glad to offer best solution for you.

Please remember we are not only auto wheel cover mold manufacturer, maker, and exporter, but also the whole line offer.

Post by Miss Mandy

Email: export@sinomould.com

Skype: sino.mould

Whatsapp: +8615757610702

With advantage of mature experience in molding and injection, we had already provided many satisfied series crate factory building turnkey project for world customers, such like, Spain, Egypt, Morocco, India, South Africa and so on.

To build a crate factory, it is very important to make schedule plan. From factory area square, wire connector, water connector, voltage and power, every step need a detail overall planning. Based on this need and considering customer actual factory environment, our turnkey line design team will use 3D software and its experience to show potential factory. After factory planning, next is for purchasing series crate machines which contains crate mold, crate injection molding machine and other accessories, such like, cuter, crusher, chiller, material auto loaders and others.

It is well known that production ability is the primary factor for purchasing machine. And this is our responsibility to put productionability as first. We know each country series crate market, and series crate popular design with practice function. Besides, our mold and injection machines will adapt linkage system which make stripper ejection and cavity ejection together, and others action at the same time. For example, crate with size 600*400*340MM, cycle time is about 53-55s. Now we improved our mold and machines with this system, cycle time is about 49-50s. This means every year,we could help customer save electricity and materials.

More information regarding to series cratesolution, pls feel free to contact.

From: Stacy

Email: export@sinomould.com

Skype: sinogroupe-62

To find one supplier can supplying plastic pallet injection molding line equipments,professional on pallet injection moding mould,injection machine, and other auxiliary equipmetns.

Standing in buyer’s point, having a turnkey solution for their plastic molding line are most important, plastic pallet are very popular and big project, this is need choose mould and machine supplier by professionally, as we know plastic pallet mould or pallet injection machine supplier have different level, differentq uality standard, also produciton line test is best way for buyer know their goods quality and running before shipment.

Sino Holdings group are skilled in customized turnkey solution for plastic pallet production line, base on our plastic moulds experience before, we know well about plastic pallet mould making, tooling, injection adjust, hor runner temperature controlling, pallet mould are special mould by multi-hot runner system and slider design, if improper operation will damage the mould, so, a injection molding line supplier with good pallet mould experiences are very help for customer.

Regarding model of pallet injection molding machine about 2000T to 2600T according to different pallet size or type, Dakumar large model injection machine with high quality configuration and strong frame for machine in high stability production.

The good after-sale service team also strong and professional, during you have planing for purchase plastic pallet injection molding line quipments, we will customize suitable soulution, including factory layout design, after-sales installtion, traning etc…welcome you contact us: Email:export@sinomould.com what’s up:86 15858625783

Plastic rattan gas assisted chair design has become more and more popular; so many customers are looking for a good plastic rattan gas chair mould maker to invest this project. As a professional plastic daily-use rattan gas assisted chair mould manufacturer, we can offer you the whole production line including the chair mould, plastic injection machine, auxiliary machine, gas assisted equipment....What’s more, we can send the engineer team to your factory to offer you the best suggestion and do the training for your employees.

For the rattangas assisted chair mould, below are some main points you should pay attention:

1. Air trapping

Mostly onthe rattan chair back place especially the forming place, there will be a problem for the air trapping, we will make inserts here to for better air venting.

2. Surface scratch

Since the chair surface is with the rattan surface finish, when finishing the injection, it is easy to have the scratch problem; you need to add the demolding angleproperly.

3. Seat place

If the customer does not agree to add the demolding angle, it needs the collapsible system, but with this collapsible system, the mould running will be not so stable and the life will not so long. If the customer chooses to do the demolding angle, the seat place will have a splitting line on the surface, so we need to check it well with the customer and choose most way to make the moulds.

4. Parting line

When the mould is finished, you need to pay attention to the parting line on the rattan chair handle place. The half line should be good, not hurting people.

5. Gas assisted

If the customer needs the rattan chair with gas assisted, you need pay attention tothe gas blowing time, gas volume, which will affect the product at some extent.

6. Robot

If this project needs to be with the automatic robot, we need pay attention to the fitting between the product and the robot. Since the pattern is rattan, it isnot so easy for the robot to take the product and also easy to scratch the product. So it is better to adjust the robot with chair before shipping.

Now we have a ready Rattan gas assisted chair production line with DKM1600T & for saleswith big discount. it is made for another customer, but he has some problem withfinance because of the exchange rate in this country. We are planning to sell this first and will remake a new one for this customer when he is ready. it is a line with gas assisted chair moulds, 1600T servo motor injection machine, robot with conveyor and gas assisted injection equipment. Welcome for inquiry!

Martina

Skype:sinomould-17

Email:export@sinomould.com

Phone/what's APP: 0086 15215807221

Nowadars , with the rapid development of society,there is a great demand for pipe fitting . And the Pipe Fitting mould is becomemore and more popular. Sino Pipe Fitting Injection Molding Line

Is widely exported to various countries.

SinoHoldings Group can provide you the most professional and comprehensive serviceand quality. Sino has already offered customers more than 50 Pipe fittinginjection molding line last year. And Dakumar Machinery co., Ltd is one of themembers of Sino Holdings Group, professional in R&D , manufacturinginjection molding machine. Dakumar machine is widely applied to thinwallpack-aging , medical parts , industrial containers and pails , automotive parts, electronic etc. particularly for our Pipefitting injection molding line , it was much in demand all over Europe,America, Asia and Africa etc.

Pipefitting is widely used in life and various industries. you can see themanywhere . Such look like Water supply, drainage, construction, agriculture,industrial water supply and sewage, valves, switches, toilet nozzles. Thematerial of it can be divided into PVC, PP ,PPR ,PE. Dakumar machinery has enrichexperience in provide a complete and professional product line for Pipe fitting.

We haveour own mould company of Sino Mould Co.,Ltd. It is the world famous Chineseplastic mould manufacturer in Southeast of China . We are good in making pipefitting moulds as bend elbow, tee, cross branch ,couplingsocket ,reduceretc.

For a complete set of PipeFitting Injection Molding Line, it must be have the following conditions:

For a complete set of PipeFitting Injection Molding Line, it must be have the following conditions:

1: Moulds

2:Injection machine (which is specially for PVC, PPRor PP various pipe fitting moulds.)

3:Auxiliary Machines

Dakumar canoffer you below equipments (auxiliary machines) for pipe fitting productionturnkey projects:

1: auto loader

2:dryer

3:water chiller with cooling tower

4:mixer

5:robot (if it is necessary for you. )

6:convey belt

7:……

If youhave this complete set of Pipe FittingInjection Molding Line from Dakumar, please believe that you not only get theproduction line, you will also have a complete set of our professional service.Our engineer will provide one-stop consulting service whatever pre sales andafter sales. If you need more information about us, please contact me .

posted by: Rose Wang

E-mail: export@sinomould.com

Whatsapp/tel:+8613738591683

Sino-PK is one of leading PET preform moulds makers in China, specialized in offering customer high quality preform mold from 8 cavity to 144cavity. If you are interested, welcome to contact us.

To make high quality preform mould, the main technical points show you as below:

Hot runner system

As you know, a good preform mould needs a good hot runner system. Because it can make sure that the material flowing can be controlled precisely in hot runner system. In addition, using good hot runner has good cooling effect,so that shorten cycle time.

Precise processing

In order to make sure the tooling tolerance of preform parts, we use advanced equipment, like Mazak high speed lathe machine to tool caviy & core , high speed CNCmilling machine to tool screw, multifunction horizontal CNC deep hole to tool hole,…

The machine for testing preform mould

Dakumar Machinery, the subsidiary company of Sino Holdings Group, is professional in offering customer high quality injection machine with different types, like PET/PVC injection machine, high speed injection machine, servo energy saving injection machine and so on. So we will have suitable PET injection machine to test PET preform mould feel free.

If you are looking for PET preform mould supplier in China, pls don’t hesitate tocontact me. We have 100% confidenceto offer customer mould with high quality.

Posted by Sara

Email: export@sinomould.com

Whatsapp: 0086 15215806623

Skype:sinomould-14

Daily using plastic drawer system are more and more used in modern life, because of lower cost than wooden drawer system, easy assembling and attractive appearance designs.If you plans to custom plastic drawer system molds, pls do not hesitate tocontact with us.

With plastic drawer system molds, we have rich experience on it, and have exported to many different customer all throughout the world, such as south Africa, turkey,Italy and so on. We develop drawer system molds with sino tooling standards,also respect customer’s special requirements. For mold steels, we normally using prehard steel, like P20, 718H, DIN2738…mold is recommended to make with hot runner system to saving material cost and good surface appearance. With drawer system molds, like drawer base mold, we also support to make it with IML molding solutions, higher performance for marketing occupation. As for drawer system shapes, we can also make it with rattan shapes, or with winker designs. Itis no problem for us to make.

We keep high orientation for plastic molding tooling in our company, every tooling technology are choose by our engineers based on detail mold structure and mold steels, it is effective saving our time and also make molds best performance. weare pleased to share with you the tooling process during mold developing. Welcome your mold inquiry on plastic drawer system molds.

Ms Diana

Mail: export@sinomould.com

Skype:sino.group01

Wechat/whatsapp:0086 13757677056

Many customers are looking for garbage bin mould supplier in China, because Chinese bin mold has advantages of good quality, cheap and short delivery time. As one of the few turnkey project suppliers in China, Sino Holdings could offer best solution for garbage bin molding line project, not only good quality garbage bin mould, but also suitable molding devices.

During the past twenty years, Sino has delivered a lot of garbage bin molds to all over the world, such like Brazil,Spain, Mexico, Italy, Israel, France, USA, etc. Different size dust bin mould we have made before such as swing top dust bin, pedal dust bin, simple dust bin,industrial dust bin mould, etc.

For bin mould, you should pay moreattention to the below points:

1. Wall thickness control

2. Cooling system for fast cycle

3. Texture or polish

4. Ejection system

5. Mould strength to afford high pressure& high speed injection, etc.

Sino has rich experience of dust bin mold making, we could handle these points well, another point also is very important for dust bin molding, it’s machine selection & adaption of ejection stroke, for industry dust bin mould, usually will use machine tonnage more than 2000T. Sino subsidiary company—Dakumar, could offer machine type from DKM50T to DKM4600T, also we could supply necessary equipment for normal production, like chiller, auto loader, dryer, etc.

Any interest for garbage molding line project, pls feel free to contact me.

Miss. Ysaline

Tel : +86 138 5763 5311

Email: export@sinomould.com

Sino Mould company professional in plastic bottle crate injection mold manufacture, mainly made for the beer bottle crate mould, cola bottle cratemould, juice bottle crate mould. Accept specialcustomized made and design upgrading. Sino mould’s bottle crate mould exported Spain,Portugal, brazil, Peru, North Africa, Middle east area, Pakistan...those famous injection molding field and receive good feedback.

For the bottle crate, customer pay much attention on the impact resistance strength and the recycle using rate. Andabout cost, some customer care more about the unit crate weight, since it is directly affect raw material input and investment. Normally, bottle crate cycle time is 45s. Through water route developing and becu ,Sino mould can help your ealize 35s-40s.

As is known to all, Sino joint stock notonly provide injection moulds, also supply customer best molding machine-injection molding machine. For machine, Dakumar injection machine is the best choice. Cooperate with Sino mould more than 15 years, They know much well about the machine how to cooperate with moulds well to reach best molding result. Normally, Our engineer with professional training, available for mouldsand machine daily maintenance and protective. If you are looking for professional bottle crate molding line manufacturer, please feel free to contact us. Now matter you have any request,Our team will support you with strict quality control to ensure mould and machine running stability and fast feedback for after sale service.

whatsapp:008615067608197

Plastic turnkey production line offer is one of most outstanding projects in Sino Holdings. With our design, tooling and equipment capacity, we are full able tosupply you turnkey molding assistance. For example, plastic rattan basket production line offer, we can serve you with below service:

1st,Whole rattan basket production line necessary equipments list, with each machine and molds target cost. For plastic rattan basket molds offer, we will supply also with pre-opening mold structure analysis, it would help us to check mold cost and more considerations based on mold quality

2nd.Combined with your factory situations, we can offer you more advice on how toconnect machines with air, waters and so on. We also able to supply you withfactory layouts to help you more effective productions.

3rd,whole production line molding supports and engineer service. It is our standardsto keep whole production lines simulation production process in sino beforeshipping, this is one inspection both molds and machines for our customer, and also will make you more satisfied with goods you have purchased.

With our rich experience on plastic molding lines, we are confident to offer you with our best quality and support. Pls feel free to contact with us if for any inquiry.

Ms Diana

Mail: export@sinomould.com

Skype:sino.group01

Wechat/whatsapp:0086 13757677056