Sino Mould is the leading plastic home appliance mold design and manufacture company, with 25 years experience, who is expert for air purifier molds, air conditioner molds, air cooler molds design and manufacturing.

Home Appliance Mold projects are not easier molds, most of them are with complicated mold structure and high requirement on product surface, so mold injection gate, mold parting lines, cooling channels design, air venting design, mold temperature controlling are very important for home appliance molds. Air purifier molds also have the similar mold requirements, like mirror polishing on front cover, back cover,and high precision tooling on blower fan molds:

Air purifier covers are made of ABS or HIPS, required shinny appearance, good polishing steel will be suggested like DIN1.2738, IMPAX, M208,NAK80, S136; And injection gate can be hot runner point gate or valve gate or direct core depended on product appearance requirements.

After moldflow analysis, we make optimal air venting system one the air purifier molds to the places where have material welding lines and air trap to avoid the welding lines or air burn marks on the plastic parts covers, and we design the reasonable water cooling system and mold structure for uneven wall thickness of air purifier mold to avoid sink marks or injection marks. Also, mold temperature controlling system for molding air purifier covers is very importance, mold temperature controller should be linked to improve the plastic material flowability to reduce injection pressure and improve part appearance.

And the keypoint for air purifier blower fan molds is the mold tooling machine, the blade shall be processed by WEDM like Sodick, Agie-Charmilles or MAKINO and balancing weight is less than 0.4 gram after balancing tested.

Sino Mould is professional air purifier molds maker in China, with experienced home appliance mold designers, accurate mold tooling machines arrangement and strict project controlling system, can supply high quality air purifier molds,air coolers molds ,air conditioner molds and other home appliance molds. Welcome to contact us for inquiry or any technique discussion!

Posted by Joyce Lau

Email: export@sinomould.com

Skype: sinomould-11 / Whatsapp: 0086 15257607361

Seau en plastique est de plus en plus largement utilisésur le marché, en particulier le seau de peinture en plastique, ainsi, les investisseurs de plus en plus tourné vers la cible de la fabrication de seau à peinture,donc, choisissez un fournisseur expérimenté et fiable est très importantlorsque vous êtes prêt à s'engager dans la production de seau à peinture en plastique.

Sino comme un fabricant chinois célèbre de moules en plastique, nous sommes très expérimentés dans la fabrication de moule de seau à peinture, par année, nous exportons plus de 50groupes moule de seau, y compris les moules de seau avec la forme de carrés, d’ovales, de rondes, nous avons fait 5Lseau à peinture, 10L seau à peinture, etc, aussi, moule de seau à peinture avec la technologie IML (étiquetage dans le moule), aussi 80L, 200L moules de seau industriels, moule de seau médicaux et moules de seau à l'eau pour différents clients dans le monde.

Mais comment faire un moule de seau à peinture de haute qualité, je vais vous présenter les détails dans l’article prochain.

Si vous avez en train de chercher un fabricant professionnel de moule d’injection pour vous offrir un moule de seau à peinture de haute qualité, svp à me contacter , Sino va vous fournir le meilleur solution !

Mlle.Ysaline

Whatsapp :+86 138 5763 5311

Email :export@sinomould.com

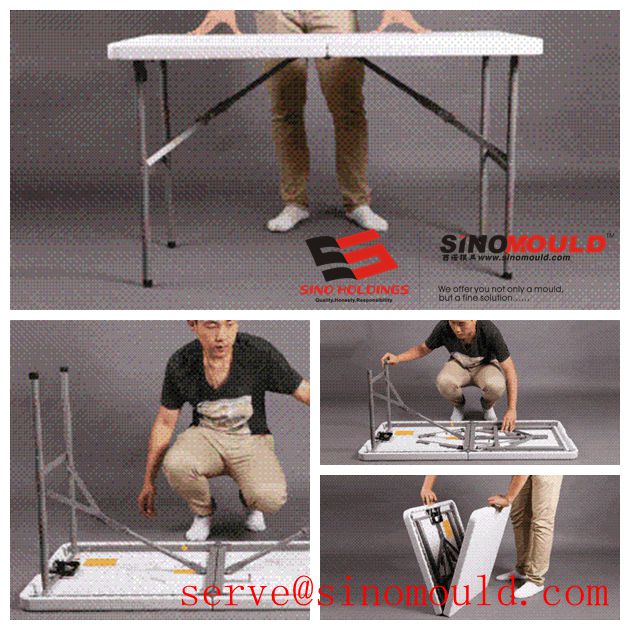

Sino Mould company specialize in research the plastic foldable table mould. In the coming Convenient way of life, plastic folding table is using frequently and it as a new product, it will widely spread used in the worldwide home and factory.

This year we are focus on the plastic foldable table injection mold research and design. We have rich experience in the foldable parts design and mould production skill, can help customer make the original plastic foldable table mould and develop the new design and help them fast occupy the sales market. Below is one type of the folding table.

We can make all parts pack in one box and make the whole set folding and open easily. Of course,Welcome customer have any new idea for the table design and work together for the plastic folding table mould. can design the size or pattern as per for your ideas and drawings and colorful, can be process by the customers’ special requirement. Also We will help you update the new style.

Folding table is very convenient for customer, and help save space. We have succeed in the plastic foldable mouldin jection molding field, each year we export more than 100sets folding type parts to the oversea market. Welcome to make detail consultation.

written by Tina

Mail:export@sinomould.com

whatsapp:008615067608197

With the speed develop of catering industry and fast food era, airtight preserving box was welcomed by many people. Airtight preserving box mould is a good choice in plastic industry. In order to meet the needs of more buyers, Sino innovated and developed a special structure in crisper injection molds.

We import several high precision machines to improve the size control, so the container and lid fitting must be in the best condition and has better sealing to assure the goods fresh. In addition, thin wall airtight preserving box has the advantage of large output. of course, our mould structure couldn’t drag it down. High function cooling system and reasonable runner design will make sure the mould cycle time around 3 seconds, compared with other supplier, our machine and molds can produce twice or thrice containers. Obviously, Sino’s technology is much more according with high speed, high precision, high safety, high stable, high energy saving purposes.

If you are looking for airtight preserving box mold maker, or want to develop your owned moulds or injection solution, welcome contact me freely. I will offer you free consultation and solution suggestion. Let’s grow up together.

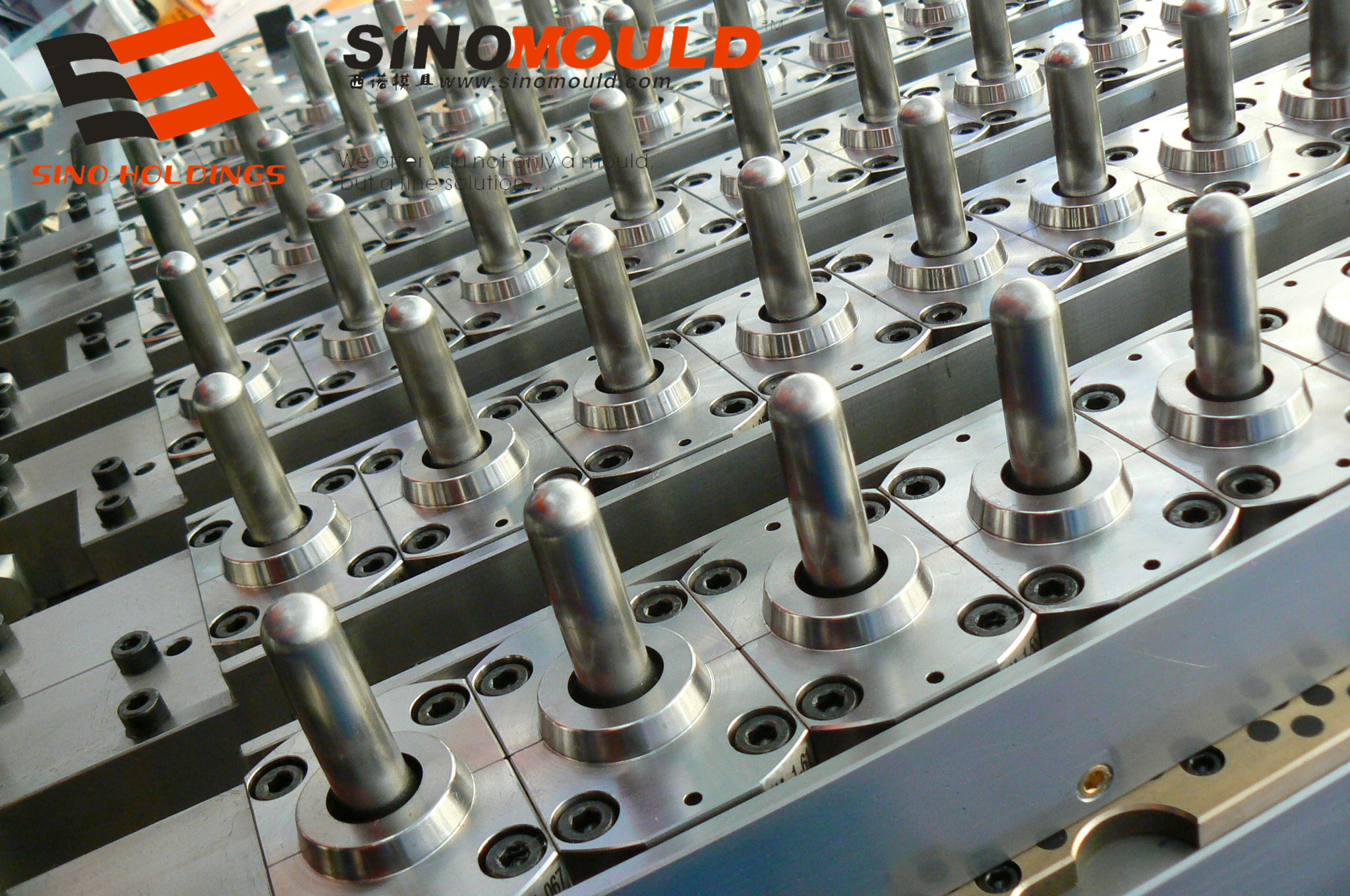

Do you want to build a complete production line for PET preform?

Sino Mould has rich experience in offering complete production

line. We have already offered many PET preform production line

for different customers, like 24 cavities preform production line

with 330Ton PET injection molding machine,16 cavities 18 grams preform

production line with 218Ton injection molding machine and 72 cavities

16 grams preform production line by using our 650Ton PET injection

molding machine etc.

One injection molding machine can produce some preforms, such as

380Ton PET injection molding machine can use to produce 1 cavity

5 gallon PET preform mould, or 16 cavities 40 grams PET preform

mould… You could make different size of PET preform on one

injection molding machine. We will recommend the best suitable PET

injection molding machine as per your preforms. Regarding the PET

preform mould, usually we will make into hot runner valve gate

in order to control the injection weight and make the preform weight

more precision.

We have service center in Argentina, Mexico, Nepal, South Africa…

And we can send professional engineers to your country to help

you set up all equipment and teach your workers how to run them.

If you want to setup whole PET preform production line,please kindly

contact me.

Posted by Erin

SKYPE:sinomould-10

EMAIL:export@sinomould.com

Sino Holdings Group providing customer all equipments for plastic logistics box injection molding or logistics container injection molding line.

To setting up logistics box factory, need to know how about Plastic logistics box injection molding equipments, it is including logistics box moulds, logistics box injection machine, robot or other injection assistant equipments…A professional supplier for plastic injection molding line supplying, Sino have rich experience on this, first the project evaluated are necessary before project start, Sino team will know from your target capacity of your Plastic logistics box, than to customized suited mould and injection machine; some high capacity customer we suggesting copper-be material with high speed injection molding machine and mould with best cooling system to reach high capacity.

For injection molding machine for logistics box, usually from 500T to 2000T according the logistics box size , Servo Motor machine are very salable for industry plastic product produce.

All customers want to see their injection molding line equipments can running be shipment, but usually they only can find mould supplier or injection machine supplier separately, very inconvenience for examine goods and shipment. Sino holdings We have very good condition for you examine and meet your request for simulated production. Also after-service, we have 10 engineers send to different country for after service.

If you are looking for Plastic logistics box injection molding line equipments supplier please do not hesitate to contact us.

Email: export@sinomould.com

What's up: 8615858625783

In the recent years, economic crisis becomes much series, there are many investors waiting and see to seek another project, which is still popular in such a situation. However, there’s an industry did not receive the impact—Children’s products. All of the parents would like to supply children the best things. So start a plastic toy storage rack mould production factory is a promising project.

Every kid has many toys, and the room will become cluttered after played with them, so one or two toy storage cabinets are very necessary to a family with child. Wooden storage cabinet is too heavy to akid; it is difficult to move them to another place. And most of the wooden items will spray paint, which has formaldehyde and other harmful substances,will danger to people’s health.

Of course, there are many parents will choose steel or alloy material drawer cabinet, because of the strong and durable characteristics. However, they are too strong will hurt kids easily. And steel product will get rusty after several years usage. In addition, the price is too expensive to buy a new one.

Therefore, if you are also interested in plastic toy storage cabinet, a good plastic toy storage rack mould maker is very important, Sino have enough experience in this or similar products. Welcome contactus freely.

Contact: Candy

whatsapp: +86-15858685263

email: export@sinomould.com

skype: anole-hc-02

Do you want to get a high quality paint bucket mold that has a long time mold life? Are you looking for a supplier who could offer you paint bucket molding line? If so, welcome to send your inquiry to me, we will be very happy to offer you a best solution for your paint bucket molding project.

Sino Holdings is very professional in offering turnkey project to our customers, we have two main companies that canoffer you high quality bucket mold and injection machine. One is Sino Mold, the other is Dakumar Machinery.

For paint bucket molding line solution,Sino could offer you the following equipment:

1. Paint Bucket Mold

We have made more paint bucket molds, for example, 5L paint bucket mold, 10L bucket mold, 20L bucket mold, also 80L, 200L industrial bucket mold, etc. Before, we made multi-cavities bucket mold, suchas 4cavity 5L bucket mold. In the bottom of the core, we add copper (Be-Cu), by this way, it could make cooling faster and reduce the cycle time. Sino could offer you a high-quality paint bucket mold.

2. Injection machine for bucket mold

For 20L plastic paint bucket, in general we use DKM450SV or DKM520SV. The injection machine of our "SV" series is servo motor machine. During cooling, the engine will not running, it can save more energy that compared with the standard injection machine.

3. Auxiliary machine

For auxiliary machine, Sino could offer you the necessary machines, such as auto-loader, dryer, Chiller, water tower, mixer,air compressor, robot, Etc.

4. System of labeling in the molds, (IMLsystem), for that, I will present the details in the next article.

More details for paint bucket molding project, welcome to contact me!

Miss. Ysaline

Tel: +86 138 57635311

Email:export@sinomould.com

Sino Holdings Group is a professional manufacturer for plastic paint bucket mould and bucket injection molding machines, we could supply high quality 20L paint bucket IML production line.Sino have more than 20years experience for paint bucket mould making, and we have supplied whole line solution for the customers all over the world.

For the paint bucket, we could make design according to customer requirement, for the water proof, drop testing, airtight, the bucket top mouth rib design and lid fitting design has different detail. Use Cu-Be for the core top insert, design with optimized cooling system, the paint bucket molding line could run fast with high speed injection molding machine.

In our present project, we have supplied our customer a new IML bucket molding line for the label with two parts, it is very important to control the accuracy for the mould tooling, machine repeat dimension and robot could send label into the mould and pick up the bucket out successfully. If you have new plan to invest the paint bucket IML production line, welcome to contact us. We could offer a fine solution for the IML moldingline include paint bucket mould, paint bucket injection molding machine and IML robot for automatically running. Thanks.

Post by Miss Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

Air cooler mold import are growing more and more in the air conditioning industry, especially from Asia, South Asia, middle-eastern like PK, India, Bangladesh, KSA, UAE...These markets need large quantities of air coolers and the popular models is 20L, 30L, 35L, 55L and 65L. Sino Mould have made complete sets of air cooler molds with different models, who is the molds supplier for AUX, CHIGO, CHANGHONG, KONCA… and OEM white home appliance makers from overseas.

Compared with air conditioners, air coolers’price is much lower, since they also make the air temperature cooler or hotter,but the temperature conditioning range is 5-10 degree, it is limited, not strong like air conditioners. Because of this factor, each air cooler manufacturers need to find very economical way to invest the air cooler molds, then they could earn more profits. Normally, one set of air cooler molds with different size of water tanks, like 25L water tank and 35 L water tanks share other parts ,invest one more mold, you could get two models of air coolers. And the air cooler moldsteel will be Bao P20 or LKM P20, YUDO hot runner or China local hot runner, mold base is SC 45, mold life time is 500,000-1 million shots, mirror polishing surface, external parts will be made of ABS, internal parts will be made of PP, some moving parts or electrical cover will be POM and PA.

Welcome to contact us for air cooler mold,with good processing, reasonable mold structure, short cooling time and easy mold maintenance. Also Sino Mould will offer you a economical air cooler molds investment solution and share you the air cooler molds injection molding experiencehelp you reduce the mold cost, labor cost and material consumption.

Posted by Joyce Lau

Email:export@sinomould.com

Skype: sinomould-11 / Whatsapp: 0086 15257607361

Plastic Molding Service supplier in China,China plastic molding service offers qualified classic Chinese plastic molding one-stop service

www.china-plastic-molding.com this website is a special chinese plastic molding companies--Sino Plastic Molding Co.

Sino Plastic Molding Co. is a professional and precise Chinese Plastic Molding service provider, it is one of the branch companies of Sino Holdings Group.

Sino Plastic Molding Co. has the serious management system for plastic components injection molding, equiped with so many high classic high speed injection molding machines and high technologies plastic injection molding experts.

For further details, please click www.china-plastic-molding.com, we are sure that our one-stop service can make you satisfied.

Sino Holdings Group is prepare to produce hydraulic electric machine,hydraulic electric injection machine,hydraulic electric molding machine,hydraulic electric plastic injection molding machine.

The hydraulic electric plastic injection molding machine will face to market on Apr. of 2012, this machine will become the topest quality precision injection molding machines of China. The technologies are researching and developed by the Sino Holdings Group for last 5 years 8 top engineers hard working results. Sino Holdings Group has already produced one 300TON and one 200TON hydraulic electric machines and has run this two machines for high speed injection molding for more than 5 months. The cycle time for thinwall injection molding 4 cavities 120ml food container mould with 4 seconds.