PET preform mould with multi-cavity solution could have high production efficiency, Sino Mould supply high quality PET preform mould for single cavity mould, 16cavity mould, 48cavity mould, 72cavity mould and so on. For all the Multi-cavity PET preform mould, we use S136 and DIN1.2316 stainless steel material for the PET preform mould core insert, cavity insert, core bushings and neck split, which is suitable for high speed running stably.

For the 72cavity PET preform mould for 28mm neck preform with weight 25g, the core and cavity insert designed with self-lock, it is interchangeable for each cavity, the after mould maintenance is very easy. With DKM650SV PET injection molding machine, the mould could run around 20s.

Sino Mould have rich experience for multi-cavity plastic injection mould, like 72cavity PET preform mould, 72cavity water cap mould, 72cavity cutlery mould, 48cavity handle mould, 24cavity flip-top cap mould, etc. With our Dakumar injection molding machine manufacturing, we supply whole production line for the multi-cavity molding solution. If you have new project for the PET preform injection molding line, welcome send us enquiry. Thanks.

Post by Miss Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

Whatsapp: 008615257606120

Dakumar injection molding machine engaged in Injection molding field more than ten years. And fast developing in the recent 5 years, We imported Euro machine production standard and technical skill to improve our machine working efficiency. Dakumar machine now is the Best Chinese injection molding machine which owns Euro standard. Now we are seeking for professional machine cooperator which can as injection machine agency in customer local market and provide fast after-sale service.

Dakumar injection molding machine which covers from50T,80T…4000t,4600T machine, Dakumar machine with big production capacity for various injection machine model. Especially for the one-stop turnkey moldingsolution offer, We offering not only a mould or machine, but a fine solution contain all auxiliary machine, engineer training and engineer oversea service for after sell. Till now, Dakumar injection machine already establish Mexico, Tunisia,Morocco, Ukraine ,Nepal, South Africa, Argentina, Morocco, Jordan etc…Wehave customers all over Europe, America, We are seeking more customers join Dakumar group and have a good cooperation.

If you are interested, Warmly welcome your down visiting and joining at Sino group –Dakumar Plastic Injection Molding Machine team, Please feel free to contact us to have detail acknowledge. Welcome to have win-win cooperation. Contact email: export@sinomould.com ,whatsapp: 008615067608197

PVC pipe fitting mould has a big demand inthe market, they are widely used for drain and sewage system, pressure fitting system, water supply & water discharge system, etc. Sino Mould had morethan 15 years of rich experience in various pipe fitting mould making, annually, we develop more than 500 sets PVC pipe fitting moulds for different countries customers.

PVC is a special material with the features of low MFI, high corrosive, low temperature melting and easy decomposition, which needs special molding process, at this point, choose a reliable PVC pipe fitting mould maker who has rich experience is very important.

For PVC pipe fitting mould making, usually, our mould structures as following:

1.Collapsible core structure

2.Curve structure

3.Unscrew structure

4.Normal mechanical or hydraulicside system

For steel, usually we choose DIN1.2738 or S136 for core and cavity, because the characteristics of PVC, we choose cold runner with submarine gate or edge gate.

For example, for TEE PVC R1/2 screw fitting mould, mould information as below:

Mould cavity: 4 cavities

Cycle time: 32s

Steel: DIN1.2738

Mould life: 1.5 million

Mould ejection system: motor unscrewing ejection

Mould dimension: 849*649*605

Welcome to contact me if you are interested in PVC pipe fitting mould making, Sino will offer best solution for PVC pipe fitting molding project.

Miss. Ysaline

Email: export@sinomould.com

Whatsapp: +86 138 5763 5311

Finding smallest plastic plant or want to know the cost to set up an smallest plastic molding line, welcome to contact Sino Holdings Group, we are the expert for plastic factory turnkey projects , and well known the smallest plastic factory cost calculation and how to build the smallest plastic factory.

As a investor without any experience for plastic injection molding business, we must care about which plastic products sell hot in my market, the machine list? What is the smallest plastic plant? And what is minimum cost this plastic molding line? How is power consumption and how much are the labor and material cost ? What’s importance , when i can get my money back?

All answers can be found in Sino Holdings Group, Sino Holdings Group with two branch companies, One is Sino Mould Co.,Ltd, another one is DAKUMAR Machinery Co.,Ltd, making plastic injection machines for 16 years, we have independent R&D team and factory to develop and manufacture our molds and injection machines, and rich experience accumulated for offer plastic products production line of food containers, PET bottles, crate/pallets, chairs/tables and home appliances. Below are the smallest plastic plant plan we suggested:

1, Takeaway food containers molding line:

One 200TON High speed machine, one set of 500ml container mold, one set of 1000ml container mold and one lid mold with auto-loader, air cooling chiller and air compressor.

2, Water bottles production line:

One 250 ton PET injection machine, with one 500ml preform mold, 1000ml preform mold, and 2000ml preform mold, one semi-automatic blowing machine with three blowing molds, and necessary injection molding accessories.

3, Crates production line:

One set of 850 ton injection machine, one set of crate like beer crate, bread crate, fish crate, vegetable crate, autoloader, water chiller, mixer.

4, Paint bucket molding production line.

10L,15L,20 L bucket moulds, one lid mould, one set of 650 ton machine,autoloader, mixer, and water chiller and one air compressor..

Which smallest plastic plant you want to invest? Please kindly tell us, we will offer machine list with cost, power consumption and productivity calculation and let you well understood the cost of the smallest plastic molding production line.

Ms Joyce

Sino Holdings Group Co.,ltd

Sino Mould Co.,Ltd /DAKUMAR Machinery Co.,Ltd

Email: export@sinomould.com

Skype: sinomould-11 Wechat/Whatsapp: 008615257607361

Sino Holdings group is with strong design and tooling ability for plastic turnkey molding productions lines, such as PC chair turnkey line service. All Sino team aims to offer diamond service and technical supports for our customer, especially for some news hands of plastic industry, and we can help you to set up factory and injection linesinstallations.

With whole PC chair molding lines, it includes mainly for below items:

Customized made PC chair mold

Injectionmolding machine with PC special screw

Robot systemfor pick up final parts

Auxiliary machineries

Due to PC material hard performance, when developed with PC chair molds, it needs high standard mold steels for forming area to make sure future high gloss surface,usually we suggest with DIN2738. Mold is with good brand hot runner for easy color changing, better to have edge gate to avoid cold material problems. For our PC chair, we use one tip hot runner + edge gate for moldings to save materialcost. High quality mold steel also can bear with around 75 degree molding temperature for good PC chairs.

With injection machines, we have our dakumar servo motor series with PC screws suitable forlong time moldings. For a armless PC chair with 850mm height, we suggest to runon our 1350ton machines. And picking up robots needs to be specially madegrippers to avoid marks on chair during taking up process. if you feelinterested, pls do not hesitate to contact with us.

MsDiana

Mail: export@sinomould.com

Skype:sino.group01

Wechat/whatsapp:0086 13757677056

Sino Holdings Group is a well-known mouldmaker and manufacturer. Our biggest characteristic is to help customers set upa full production line. Especially we have a wealth experience in setting upthin wall box production line, it is widely used in different countries, like African,south American, Turkey, Mexico and so on.

We have professional team to help you setup a new production line, and we have several advantages in offering productionline as below:

1.Sino professional thin wall boxmould

We have our own mould company- Sino mould. It’sthe world famous Chinese plastic mould manufacturer in southeast of China andit has a great achievements in a plastic mould design and manufacturing. Weprovide you a full set of service which is the most suitable to you. For thinwall box mould, we will suggest you to use S136 steel material ,and the wallthickness can be 0.44-0.55mm . We have sold more than 500 pairs thin wall boxmould.

2.High speed injection machine.

Zhejiang Dakumar Machinery Co.,LTD is oneof the members of Sino Holdings Group which is specialized in making variouskinds of plastic injection machine. DKM high speed injection machine is good atthin wall box manufacturing. It can in ensuring high speed, safety, energysaving basis and improve production capacity, increase revenue as well. We havethe type of high speed machine from 200H to 600H, and our cycle time can reach3.8s-6s.

3.Auxiliary equipments:

We have all kinds of auxiliary equipmentsfor your choice. Such as : auto-loader, crush, cooling tower, mixer …and so on.

In summary:

1、We have set up about 50 thin wall box production line lastyear. So don’t worry about the after-sales service at all, we have professionalengineer to help you handle it in time.

2、We provide you the highest quality with best price and the mostintimate service .

3、And we offer you our own mould ,machine, auxiliary equipments and ourprofessional train, whether or not there are some problems you are meeting, wecan provide you efficient service timely.

4、If you purchase machine and mould from different supplier, may bethere will have many argues between you and suppliers, you will waste money andtime too, and it can not solve problem in a short time.

We are committed to becoming the best thinwall box production line supplier, if you are interested in it, please contactme.

In 2016 years, Sino has made around 20 fast-food boxes production line for more than 100 box models. Thus it can be seen how good the fast-food boxes market prospect. Here we found some reasons why fastfood box becomes so popular in plastic production market.

1.Low cost: normally, one 1L box with lid weight is around 20g, changed to plastic material cost is USD0.028/pc. Included the labor, electric and other cost, the amount couldn’t more than 0.035. at last, we add the mold cost around USD25000-30000. The mold can produce more than 5 Million shots under generally maintenance. So the cost is around USD0.007.

In addition, we will make 2 cavities mould at least, so the cost will be reduced half. In this way, the complete fastfood box cost won’t be more than USD0.042.

2.Large market demand: a city which has 4 million people, 1 person 1 box, so 1 year need 1.46 billion food boxes. But some of the foods not only need 1 box. How many molds can be used for production to satisfy such a large market demand?

According to Sino’s 4 cavities thin-wall injection mold, worked with robot can realize the cycle time of 4 second. 1 year can produce 0.31 billion.

From here, we know the fast-food boxes market prospect is very huge. Sino owns 24 years mold and injection machine production experience, choose us just means choose good business opportunity.

Contact: Candy

Email: export@sinomould.com

Skype: anole-hc-02

Whatsapp: 008615858685263

We have rich successfully experiences for various high speed thin wall container molds, like thin wall ice cream box mold, disposable food container mold, square cheese box mold, 1L bucket molds and so on. SINO Mould has professional team for thin wall product molds’design and tooling. We applied the latest suitable solution for mold.

Considering about good mold quality,SINO choose the strong mold structure for thin wall container mold which suitable for high speeding running. Like for multi-cavity thin-walled box mold,SINO prefers to choose self locking structure rather than solid structure. Because self locking structure means one cavity one block, it’s easily your future maintenance,product wall thickness adjustment and dimension controlling. Also it can strong mold with clamping to longer mold life. But this mold dimension is larger than solid structure (all cavities one block). This year, we support our customer with the 4-cavities food container with 0.35mm wall thickness.

As China top thin wall container molds maker, we will support tailor made solution for your projects. If you plan to start new projects for thin wall container moldings, pls don’t hesitate to contact us with details product information.

Posted by Ms. Helen

Cell phone: +86 15858625783 (whatsapp/wechat / line)

Email: export@sinomould.com, export@sinomould.com

Skype: sino.group10

Pipe fittings are widely used in our lives,usually with material of PVC, PPR, PP, and PE, according to different shapes, pipe fitting will has below application:

1.For pipe interconnection

2.Change the pipe direction

3.Change the pipe diameter

4.Increase the pipe branch

5.For pipe sealing

6.For pipe fixed, etc.

You may plan to set up a pipe fittingmolding factory to offering various types of pipe fitting products, if so, welcome to contact me to know more, Sino Holdings group could offer you bestsolution for pipe fitting moldingfactory setting up.

For setup a pipe fitting molding factory,you need the devices as flowing:

1.Pipe fitting mould

Sino had more than 15 years of rich experience in pipefitting molds manufacture, our R&D Dpt. has strong design capacity forirregular shape fitting mold making, such as collapsible core system, curving sliding system, automatic unscrewing system, etc. Every year, Sino exports more than 500sets high quality pipe fitting molds in the international market, wecould offer you best solution for pipe fitting mold.

2.Injection molding machine

Our subsidiary company—Dakumar Machinery, could offer youall kinds injection molding machine, the machine type from 50T to 4000T, usually for pipe fitting mold production, the suitable machine type usually from DKM118T to DKM550T.

3.Auxiliary machine

For normal production of pipe fitting, the auxiliary machine essential such as chiller, dryer, dehumidifiers, auto loader, aircompressor, etc.

If you want to start your business from pipe fitting, welcome to contact me, we will be happy to offer you professional and best solution for pipe fitting molding project.

Miss. Ysaline

Watsapp: 0086 138 5763 5311

Email: export@sinomould.com

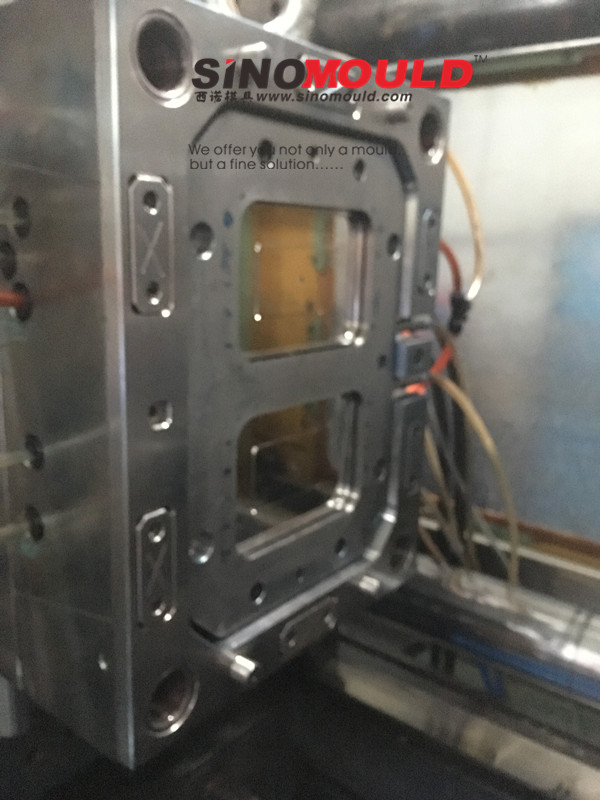

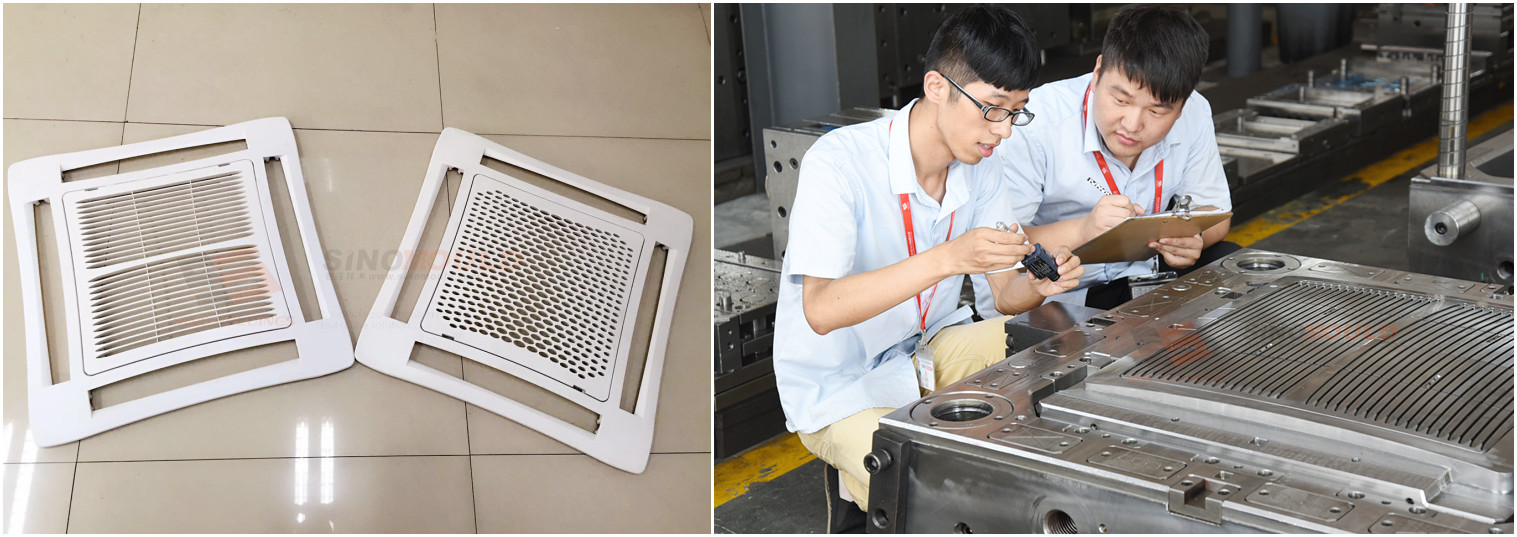

Electrical home appliance mould requires a very good mold design team, reasonable tooling procedures arrangement and experienced plastic home appliance mold project management, to control the mould dimension strictly and make decisions with suitable home electrical appliance mould assembly modification solutions.

In Sino Mould, we will go for 4 steps: 1st step is product design analysis and mould design analysis, we will have meetings to find out optimal mold design as per the experience accumulation and moldflow anaylysis and also can offer rapid protyping for initial product design and assembly approval, marking every mould parts with accurate processing tolerance and suitable moud processing machines arrangements. 2nd step is strict electrical appliance mould parts dimensions precision controlling and high response mould spare parts purchase to make sure every elements on our electrical home appliance moulds are through quality inspection and dimension precision inspection;And the 3rd step of our electrical home appliance mold construction is the mould testing data analysis, careful and patient moulds testing adjustments to find out the best home appliance molding datas and keep notes for the all the defects of moulds and products,after 24 hours, checking assembly and make testing samples dimensions inspection, then project managers hold meeting with designers and mould technicians to make the mould modification report or refine solution according to the testing reports, parts dimension inspection report and assembly result.

What’s more, Sino Mould can offer the 4thstep is small trial productions for all the electrical home appliance moulds, after 500 shots or 1000 shots production, the moulds’ performance will be more stable and injection machine adjustment data will be more valuable for the customer’s mass production.

Sino Mould is specialized in electrical home appliance mould R&D, with advanced mould design solution and high precision processing machines, hope we have the chance to fabricate your home appliance mould and offer a very fine solution for your electrical home appliance moulding business.

Ms Joyce

Sino Holdings Group Co.,ltd

Sino Mould Co.,Ltd /DAKUMAR Machinery Co.,Ltd

Email: export@sinomould.com

Skype: sinomould-11 Wechat/Whatsapp: 008615257607361

Dakumar machinery we are seeking agent fromvarious countries for our injection molding machines, and we want establish agent for injection machine in Iran or machine sale representative andafter-sale center.

Dakumar machinery Co we are manufacturingplastic injection molding machine from 50Ton to 4600Ton, for some large tonmodel injection molding such as 3500Ton, 4000Ton, 4600Ton it is very lesssupplier make be produce, Dakumar are R&D 4600ton machine and alsotwo-platen injection machine, our target is make our machine to euro standard.

Besides, Dakumar Machine is below to SinoHoldings Co, our plastic injection molding line are also attractive, we haveprovidered many production line for many projects, our vision is : to providertop quality turnkey injection molding line equipments.

Dakumar has established many agent inmulti-countries, like Mexico, Jordan, South Africa, Morocco, Tunisia, Ukraine,Argentina etc..we have sold many machines to Iran although we have capacity forservice, but considering Dakumar machine entry Iran market very fast and verygood market feedback, so we are finding and to choose a good ability Iraninjection machine agent, to provider our customer in high quality and timelyservice.

We have visted Iran, Tehran some officebefore,we want establish Iran injection machine agent, welcome you contact usif you are injection industrial or you have experience for injection moldingmachine. Email: export@sinomould.com ,what’s up: +86 15858625783

If you don't have experience for plastic product manufacturing business, it will be headache to contact many kinds of suppliers, someone is making plastic injection molds only, someone is making injection molding machines only,also someone is making injection molding accessories, you could not know a complete information about how to set up plastic products making factory or start plastic product manufacturing business and how many machines needed for this factories and how is plastic molding factory investment. They are not the experts for plastic products molding line business.

All these problems can be avoided in Sino Holdings Group Co.,Ltd(Sino Mould Co.,Ltd and DAKUMAR MACHINERY CO.,Ltd). SinoHoldings Group devoted to offer the top grade plastic molding factories turnkey project service and would like to provide plastic molding solutions to new plastic products factories setting-up and technique supports in overseas. We are the expert for high quality plastic molds manufacturing and molding service for more than 20 years, and have injection machines manufacturing factory-DAKUMAR. We can supply factory layout design with water lines and power lines injection molds, injection machines, injection molding auxiliary machine, robots,automatic production devices and overseas engineering service for the people who want to start plastic product manufacturing business. Till now, we have finished new plastic products making factories like thin wall containers food package production line, daily use production lines, home applaince parts production lines, crate/pallet production lines, chair/stool/table production lines, 4L-20 L paint bucket production lines and water bottles and cap production line, PVC pipe fitting production lines...Around 300 new plastic products making factories have set up in South Africa, Mexico, Russia, Spain, Jordan, Guinea, Nigeria, Benin, Ethiopia, Uganda,Angola,Morocco, KSA,Columbia, Venezuela... We have rich experience for plastic production manufacturing business investment and well known of how to recommend the optimal configuration for plastic products making machines and devices.

Welcome to contact us for new plastic products making factories setting up, and we will give you a complete information for plastic product manufacturing business with fine solution and economical investment.

Ms Joyce

Sino Holdings Group Co.,ltd

Sino Mould Co.,Ltd /DAKUMAR Machinery Co.,Ltd

Email: export@sinomould.com

Skype: sinomould-11 Wechat/Whatsapp: 008615257607361