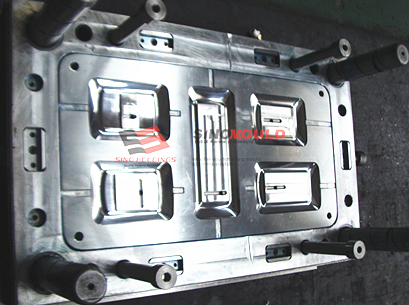

Sino Mould company China is a professional manufacturer for plastic injection moulds, we supply high quality mould for high lighting plastic mould, with shinning surface, the mould could run well automatically with mould temperature controller in order to keep the mould temperature to certain level.

For the plastic high lighting mould, usually the mould steel material required with good polishing, it is suitable for out surface household appliance product mould and lighting system mould. We use good steel material like DIN1.2738, 2344, NAK 80, S136 and some other mirror polishing steel material. For the plastic raw material, usually we use ABS, PC, PMMA or some other plastic raw material which could reach to high shinning surface. The Mould temperature we have to keep above 60centi degree in order to get good lighting view.

Sino Mould have experience mould making experience more than 10years ago, we make cell phone case mould, name card case mould, ice box case mould and other moulds with high lighting plastic mould. With this technology, the product is high quality and no need other surface coating after molding. We could supply whole molding line solution for the high lighting products molding. Welcome to contact us for more information. Thanks.

Post by Miss Celina

Email: export@sinomould.com

Skype: sinomould.dakumar7

SINO HOLDINGS GROUP is a professional IMLpaint bucket production line supplier. We have gathered rich experience in IMLpaint pail molding solution, We also offer diamond service to IML bucketturn-key project.

We makes around 500 sets bucket mouldsevery year. Some fault experience in the beginning which made us headache also makesus grow up very fast from experience. We learn to solve the problem and workingbetter and better in this field. For IML paint bucket moulds, we suggest to useDIN1.2738, 718H, P20, Be-copper for the mould core and cavity. The reason weadd Becu on bucket core top is to reduce mould cycle time. For example, 20Lbucket common cycle time is around 25-30 seconds. With Becu the cycle timecould be 23-25 seconds.

Beside the IML paint pail moulds, we alsoselect suitable injection machine, robot and auxiliary for customer. Thecomplete set moulding line equipment will be cooperate well before shipment.What customer need to do is:

1)Prepare the budget.

2)Search for market

3)Select samples

4)Rent workshop

5)Find good IML paint pailproduction line supplier.

SINO HOLDINGS GROUP will be the company whoyou looking for. Welcome to contact me for bucket project discuss.

Email: export@sinomould.com

Skype: sino-mould02

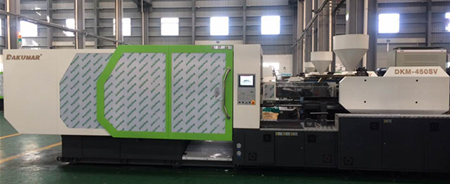

Dakumar Machinery, branch company of Sino Holdings Group, is professional for plastic injection molding machine manufacturing with various types, include servo power saving type, high speed type, variable pump type, special engineering material type and stable pump type injection molding machine. We could supply the machine size from DKM50 until DKM4000 with whole production line service. We are looking for plastic injection molding machine agent and service office setup in different countries in Africa, Middle East and South America.

Dakumar injection machine manufacturing start at 2007, at the beginning, we setup new injection molding machine manufacturing company in order to support the mould customer new production line project, we could supply together with plastic injection mould, injection molding machine and also other necessary additional machines. For the whole production line, we could supply high quality injection molding equipment, technology solution and service. We need more injection molding machine service office for different production line setup all over the world.

Our service range include PET bottle production line, chair production line, crate production line, thin wall container production line, IML molding line and so on. If you are professional in plastic injection molding machine operation, and interested in cooperation with Dakumar injection molding machine, we could come together and discuss the plastic injection molding machine service office and agent setup details. Welcome your enquiry. Thanks.

Post by Miss Celina

Skype: sinomould.dakumar7

Email: export@sinomould.com

Sino Package Mould Co. has successfully tested the 2nd 72 cavities PET preform mould on Jul 26th, 2011. This 72 cavities pet preform mould with the preform weight 43g. The mass production simulation time is 26 hours continuesly. This indicated that Sino Package Mould Co's PET preform mould innovating and researching has approach mature technologies and experiences.

Welcome the high classic preform mould mould custom from us!

Post by Miss Coco export@sinomould.com

On Jul. 26 of 2011, Sino Mould has successfully done the 1st short for one PS cup mould.

This PS cup mould specifications:

cup wall thickness 0.45mm

diameter 50mm 40mm

mould with 4 cavities valve gate hot runner system

mould steel: Stavax S420 steel tempered.

cup mould cycle time 5.3 S

This is the 14th similar PS thinwall cup mould which are 4 cavities that Sino Mould has delivered.

Post By Miss Coco export@sinomould.com

AsiaMold 2011

World professional exhibition for for Mold manufacturing and Tooling,

molds and tools design and Application Developments.

Date: 21-Sep-2011 to 23-Sep-2011

Exhibition Timing: 09.30am - 05.30pm

Suitable Industry: Industrial & Engineering Products, Spares and Supplies

Exhibition Place: Poly World Trade Center Expo, Guangzhou, China

Halls: 1.0, 2.0

No of Halls: 2

Organizer: Guangzhou Guangya Messe Frankfurt Co Ltd

AsiaMold 2011 Profile

AsiaMold is the only international mould and die exhibition in China to feature the entire process chain

“From Design to Prototyping to Series Production”. This targeted approach closes the gap between industrial

designers, product developers, producers, suppliers and end users – through innovation and synergy.

AsiaMold 2011 will therefore not only be a perfect occassion to build your brand, but also a venue to

initiate and strengthen your strategic alliances for manufacturing, outsourcing, sub-contracting,

design and development as well as direct marketing

2011 SHANGHAI APPLAS Asian-Pacific International

Date:2011/9/6 - 2011/9/9

Address:Shanghai New International Expo Center (SNIEC)

(No. 2345 Longyang Road, Pudong New Area Shanghai )

feauring: automotive parts mold, aluminum or Zamark Diecasitng moulds,home appliance parts mould,4 cavities crate mould,high speed crate mold, bottle crate

&pallet moulds,chair mould, table mold,bucket mold, packing mould,industrial garbage bins &house hold dust bins mold, thinwall injection mold, stacking mold, etc.

coordinator: COCO MSN:export@sinomould.com

Email: export@sinomould.com

Cycle Time, refers to the time required from mold close, material injection, mold cooling, mold open, product ejection, and, in the case of inserts, reset the mold.

On September 9th, Sino-PK had successfully done the 1st testing of

The flip top cap mould specification is as follows:

flip top cap mould with 24 tips hot runner system

cap weight: 1.15g

cap diameter: 15mm

mould steel: Stavax S420

flip top cap closed automaticly by the mould mechanical action before ejection.

Sino-PK has achieved big success in flip top cap mould with in mould closing system.

Post by: Rita Email: export@sinomould.com Skype: sino.group06

iPhone 5 case

iPhone 5 case is the special case made for iPhone 5, SinoMould made more than 5 differnt iPhone 5 case mould with different case molding material for iPhone 5 case.

iPhone 5 case mould's T1 will be on the end fo Sep., these moulds are worked with Sweden S136 Stavax, this is one of the best stainless steel and durable. it is suitable for more than 10 million shots iPhone 5 case injection molding. The iPhone 5 case will be injection molding, pressing molding and other newest plastic molding processing. below is the iPhone 5 case plastic or leather molding process types.

iPhone 5 case plastic with IMD processing ( same finishing as iPhone 5 itself )

iPhone 5 case plastic with rubber finishing

iPhone 5 case plastic with metal finishing

iPhone 5 case plastic with different colors finishing

iPhone 5 case plastic with diamond decorated

iPhone 5 case with silicon ( soft and transparent )

iPhone 5 case with transparent hard PC material

iPhone 5 case with rubber

iPhone 5 case with PVC soft molding

iPhone 5 with leather finishing

SINOELE is the biggest iPhone 5 case manufacturer in China, the molds are made by SINOMOULD.

Injection Molding Machine | Injection Molding Machine China | Injection Molding Machine Manufacturer

Injection Molding Machine,injection molding machine china,injection molding machine manufacturer,Dakumar Injection Molding Machines is the qualified injection molding machine supplier in China.

Dakumar Injection Molding Machine has delivered 485 sets to oversea from Jan 1 to Oct. 10 of 2011. Hopeful in 2011 year, more than 600 sets of injection molding machines are able to be delivered.

Sino Holdings Group injection molding machine producing and service has became the group's another developments emphasis, Sino Holdings Group are considering to invest more than 20M USD for new tooling machines and RND centers for injection molding machine manufacturing and developing.

Injection Molding machine's developing planning for DAKUMAR is as below:

Keen on developing the energy saving injection molding machine. Heating energy saving nd actions energy saving.

Keen on high speed injection molding machine developing.

Keen on machine precise injection molding.

Developing for huge clamping force injection molding machine such like the machine bigger than 2000TON.

In order to produce high precision injection molding machine, Sino Holdings Group invested a lot of tooling machines to make all the mechanical components high precise, based on the strong frame and stable high re-action controlling system, high precised mechanical components guarantee high speed injection molding.

Due to the large tonnage injection molding machine production, Sino Holdings Group invested an huge workshop which the floor can loan and the crane can lift more than 150TON weight of machine or parts group.

Dakumar Injection Molding Machine is now growing very fast, this injection molding machine brand has a very brilliant future. Injection Molding Machine for high speed, injection molding machine stable and energy saving.

Overmolding injection technical is an over molding technologies which discribed different material over molding process,this topic talked overmolding injection keypoint.

Overmolding injection technical is the injection process for two or more type of differnt plastic material jointed during their melting after they were filled into the molds cavities.

Overmolded plastic components are such like, tooth brush, kids care products, pnuematic tools handle, car lighting system (tail lamps lense).

Overmolding processing has two kinds of way.

the different materials or different colors were jointed by out of the mold, this meaning, one molded ready one of the part can put it into an other mold for second or third material (colors) injection.

the multi-material or multi-colors injection molding and jointing inside of one mould and done by one machine.

The 2nd processing of overmolding injection has two types.

One is by the injection molding machine's clamping plate rotary.

The other is by the injection molds' inside medical action to realize the 2nd material injection filling and jointing.

Overmolding injection mold and machines are high precise and high technologies requirement. SinoMould offers turnkey project for machines and various of molds, also help our customer to run the machine in their workshop.

POST by Miss Marry from Sino Holdings Group.

export@sinomould.com / export@sinomould.com

Skype: sinomould-06