In recent years, rattan plastic products are popularity in dailylife. SINO designs and tools various rattan product molds, rattan laundry basket molds, wicker plastic chair molds, custom-made rattan table molds, rattan drawers molds and rattan storage box molds.

Compared with traditional plastic laundry basket molds, tailor rattan basket molds required professional molds supplier for providing suitable mold structure to realize true-to-nature rattan effect, meanwhile keep good demoulding. As know to all, two sides rattan product molds complex than one side rattan mold. SINO team has rich successfully experience for rattanproduct molds, rattan gas-assistant chair mold, and two-side wicker chair molds…

For example, our Denmark customer’s double-wall wicker gas assistant chair molds, we keep reasonable draft angle to ensure good demoulding without tear produc surface. At same time, we keep true rattan feeling with help of high precision CNC milling center from Italy and Sodick wire cutting equipment.Before your rattan linen basket project beginning, we will do Moldflow to simulate real molding condition. Also, we hold a meeting for analysis mold project details, mold design structure/ cooling system/ejector system/injection systemand so on.

SINO Mould is expert for plastic injection molds, especially for high standard injection rattan product molds. We also supply prompt molding service for your plastic projects with all necessary equipments.

Posted by Ms. Helen

Email: export@sinomould.com

Skype: sino.group10

Cell phone: 0086 15858625783 (Whatsapp /Wechat/ Line)

With the development of science and technology, People's requirements for plastic paint pail is getting higher. And now automatic mechanical operation gradually replace manual operation, at this time, for paint bucket mold making, automatic in mold labeling system is becoming more and more popular, plastic IML paint pail has a great demand in the market.

Sino Holdings as a famous manufacturer of injection mold and injection machine, who could offer you plastic paint bucket production line. We offer you not only paint pail mould, injection machine, but also auxiliary machines, also, we could offer you IML system for bucket mold.

Forin mold labeling system, we offer you as below devices:

1.Robot for label collection

2.Robot for feed the label into the mould and pick out the plastic labeled parts.

3.Labels

4.Robot to stack plastic labeled parts,

5.Conveyor, etc.

Sino-Dakumar machinery offer you the injection machine for IML paint bucket production, in general, for 20L IML pail bucket mould, we recommend use DKM-650 servo motor injection machine, compare with standard injection machine, more energy when cooling.

Choose Sino, we could provide you the best solution for Paint Bucket Molding Line project. If you are interested in this turnkey project for pail bucket production, please contact me.

Miss.Ysaline

Tel:+86 138 5763 5311

Email:export@sinomould.com

In order to support customers with more convenience and professional assistance for new plastic production lines building up, sino holdings is in the lead of offering turnkey molding solutions, whatever new projects or new factory build up, such as plastic cap molding lines.

We successfully delivered many plastic packaging molding lines to different countries. For plastic cap molding solutions, we aims to offer you:

1. Initial cap molding lines project budget analysis

2. Both cap & molding machines equipment design and develop

3. Plant fundation supports like water/air/electrical design, this is more suitable for new cap factory building up

4. Engineering service & training

......

With plastic cap molds, it is design and manufactured by our sino packaging, which is only focus on different cap molds making and innovate mold structure and functions real time updating. We make standard water cap molds, flip top cap molds, push pull cap molds and so on. with customer’s using feedback, it helps sino team to grow up and making molds more suitable for your productions.

Together with cap molds, we can also offer you cap injection molding machines, cap molding auxiliary machinery like auto loader, water chiller... All what we can do is to have one stop molding service for you, saving time and cost for whole production lines.

If you plan to start new plastic cap/closure molding projects, pls feel free to contact with us.

Ms Diana

Mail: export@sinomould.com

Skype: sino.group01

Wechat/whatsapp: 0086 13757677056

In the daily life, plastic pipe fitting is widely used and more and more customers begin to invest this project. As we are professional in making all kinds of plastic injection pipe fitting moulds, such as tee, reducer, elbow, coupler, union, cross …

Usually the plastic material for the pipe fitting is the PPR, PE, PVC. The material is depended on its function, if it is used in the architecture, underground pipe, mostly will choose the PVC which has the function of flame retardance, wear-resisting. If you use in daily water pipe, it will use PPR which is safe material. Also the mould steel will be different, for PVC pipe fitting, 718H, p20 is ok.For PVC pipe fitting, 2316,S136 is ok.

The demoulding ways for the pipe fitting we usually has 5 ways:

1. Screwing demoulding

2.Curve sliding demoulding

3.Collapsible demoulding

4.Horsing demoulding

5.Directly demoulding

For the plastic injection pipe fitting mould, we can do the interchangeable part of the screw, size ..which will meet different customers’ different requirement, also it can reduce the investment. The biggest size we have made before is the¢410、¢320和¢250 .

For the plastic injection pipe fitting moulds, we have much experience in making big and small collapsible structure , also the mould movement is very fluently , so if you are interested in the plastic pipe fitting mould project, pls kindly contact me.

Martina

Skype: sinomould-17

Email: export@sinomould.com

Phone: 0086+15215807221

Sino Mould is professional for household appliance mould manufacturing, we supply plastic injection mould for the whole set washing machine, include washing machine hatch frame mould, main body mould, plastic inner parts mould and so on. It is very important to make the part with precision dimension in order to get all the parts assembling well and assembling easily. We could supply high quality washing machine mould with one stop service.

For the washing machine hatch frame mould,it is the moulding part used in the outside of the washing machine, people put the clothes into washing machine or take out clean clothes through this hatch frame, it is important to make the part without flashes, burrs, or any other sharp edges. And the outside view of the hatch frame must be looking nice.During the mould design, we need to consider the sink mark, injection gatelocation and size, etc. Usually for the hatch frame mould, the plastic raw material is ABS, we have to use mould temperature controller to heat the mould to get shinning product. Sometimes customer use painting for the outside of the hatch frame part after molding.

Sino Mould is good at making high quality washing machine mould for hatch frame, main container and other parts mould,all the product design, mould design and mould tooling is completed in our own workshop by Sino professional team. Welcome to contact us for more information about Sino Mould household appliance mould making. Thanks.

Post by Miss Celina

Skype: sinomould.dakumar7

Whatsapp: 008615257606120

In the recent year developing, More and more chair making company pay much attention on the baby chair's safety andstrength. To a large extent, it has an indirect effect on the production standards and production costs of the tooling suppliers as well as the innovation in the design. Sino mould company famous in the plastic industrial area for the kiddes chair mould manufacture. And rich experience for the baby using parts, like Cello rock chair mould, toys mould, toilet mould..etc, These moulds we will talk in the following article.

Like adults chair mould, Kiddies chair mould can be design withdifferent shape, with leg or without leg, with arm or armless chair mould. But on the material choosing, most baby chair factory choosing the 100% pure and non-toxic plastic material. And special treat for the injection molding spuremark,to avoid hurt baby by accident. On design ,Sino mould pay much attection help customer develop lovely baby chair design to attract the eyes of the vast number of consumers.

Sino mould made so many years baby chairmould, Our team understand make which kinds of solution to make best strengthkiddies chair mould. Sino mould baby chair mould mainly consider for baby care. Choose SINO MOULD, to realize win-win market.

Whatsapp:008615067608197

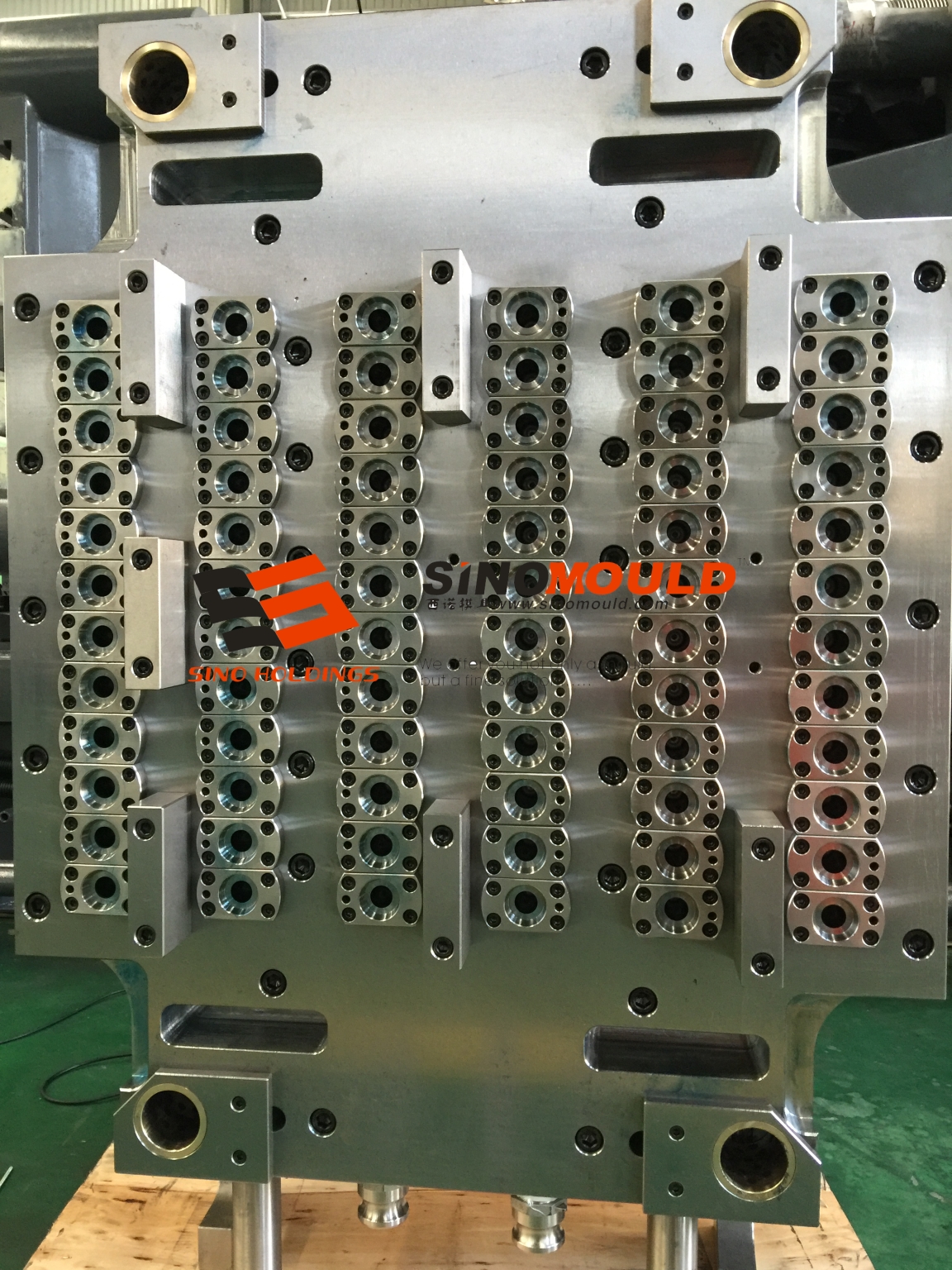

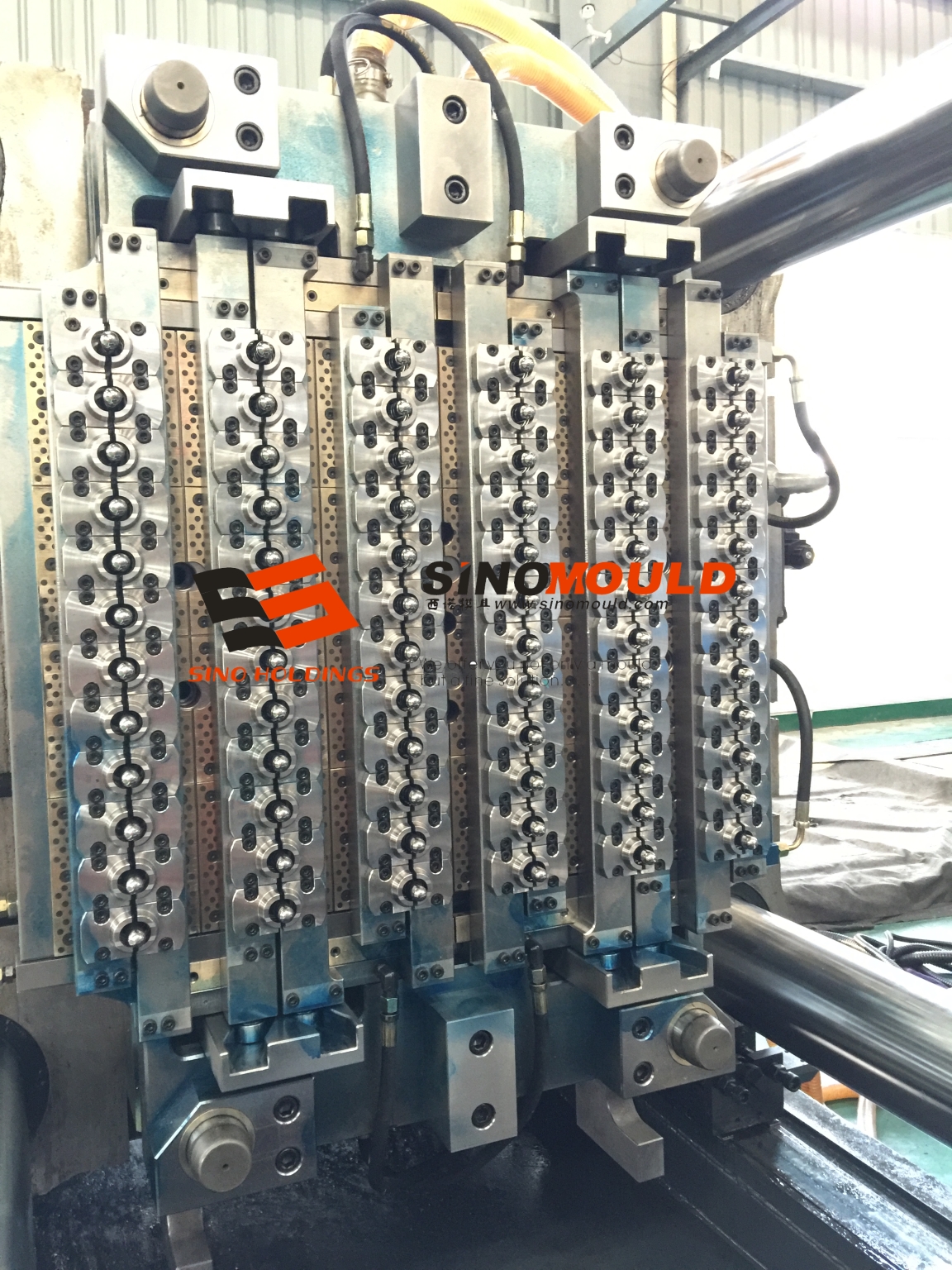

Customer always very care about the preformmold cycle time, because time is money. High speed multi cavity preform moldscan help you turn investment back quickly. SINO MOULD is a very professionalhigh speed multi cavity preform mould manufacturer.

If you already have experience in buyprefrom mould from China, you will know the mould price will be much lower thanEurope mold and other countries, and the mould quality is also good. Chinesemoulds price also very difference from different mould supplier. As a mouldsupplier, we always believe an old saying “ the benefit comes from investment”. If you looking for high speed multi cavity preform moulds, the supplier’sexperience is very important. For preform mold cavity number over 48 cavities,the mold development technical difficulties increase a lot.

SINO MOULD has gain a lot of achievement inpreform mould manufacturing, especially for 72 cavity preform moulds.

Fornormal 28mm neck 20 g 72 cavity preform mould, our cycle time is around 15-17seconds. This mould will need injection molding machine clamping force around650 tonnage. An excellent preform mould cooling system design and injectionmachine performance is the biggest two factors to the cycle time. For moreinformation about SINO preform mould, welcome to contact sales manager Summer.

Email: export@sinomould.com

Skype: sino-mould02

Sino Mould company China is a top thin wall container mould maker in the world, we supplied different size thin wall container mould for ice cream container mould, disposable food container mould,paint bucket mould and so on. Our main market for plastic injection mould is in Middle East, South America, Africa, etc. We could supply thin wall container mould with high speed injection molding machine for thin wall container production line.

Thin wall container mould need to use high quality steel material with good polishing, it is suitable for high speed running. We use S136 stainless steel material, with fully hot runner system pin point gate or valve gate injection. We have rich experience for multi-cavity thin wall container mould, such as 2cavity mould for 1gallon bucket mould,4cavity mould for 1L thin wall container mould, 6cavity mould for 500ml thinwall container mould and so on.

Sino Mould supply top quality thin wallcontainer mould, we could offer one stop service for thin wall container production line, include thin wall container mould, high speed injectionmolding machine and other necessary additional machines. Welcome your enquiry with detail information about your product, we will response to you soon.Thanks.

Post by Miss Celina

Skype: sinomould.dakumar7

Email: export@sinomould.com

PlasticMetical mold is included syringe barrel mold, syringe gasket mold, syringe plunger mold and medical cup mold. Today, let us talking about plastic medical cap mold.

Measuring cup mold is popular in medical world because it has many usage. As we all know, metical products usually use just for one time, so it will have high production requirement in our production. Because of this,there are more and more measuring cup mould maker and exporter in Huangyan,Zhejiang.

Measuring cup mold is one of the medical mold, we Sino package mold specialized in. Followed is the information about the measuring cup mould:

Cavities: 12~64cavities

Cavities & core material: S136

Runner : Anole point gate

Product Material: PP or PET

Finishing: mirror polishing

Inserts interchangeable

Mould life:3 million strokes

Sino Package mold, professional for plastic injection package mold, have almost 10 years for package mold, such as PET preform mold, syringe mold, medical cup mold, and different kinds of cap mold and so on.

We also have brother company for plastic injection molding machine, So we provided all set of plastic injection molding production line, can offer clients a perfect plastic injection molding solution.

If you have a problem, please do not hesitate to contact me.

Posted by Snow

Email: export@sinomould.com

Skype:sinogroupe-71

Pour la production de moule de seau à peinture à longtemps, il est très important d’avoir un moule de seau à peinture de haute qualité, mais comment faire un moule de seau debonne qualité ?

D'abord, choisir un acier approprié, habituellement, nousutilisons S136, DIN1.2344, DIN2738, et DIN1.2311, choisissant un acier approprié qui est bon pour le polissage, il pourrait garder un bon effet desurface. Afin de faire le temps de cycle rapide, nous ajouterons BeCu dans lefond de noyau, par exemple, avant nous avons fait le 15L seau de peinture qui ajoutent BeCu, le temps de cycle est de 12S. Bien sûr, pour le temps de cycle rapide, non seulement dépend de BeCu, mais aussi un bon système de refroidissement et machine d'injection.

Sino comme un fabricant de moule qui est l'expériencedans la fabrication de moule de seau à peinture, pour le système de refroidissement, nous savons comment concevoir le système de refroidissement pour garder le meilleur effet de refroidissement, avant la fabrication de moulede seau à peinture, nous ferons analyse de flux de moule pour éviter certains défauts inutiles, Par ce moyen, nous pourrions faire moule de seau à peinture de bonne qualité avec le temps de cycle rapide et le délai de livraison court.

Si vous êtes à la recherche d'un fabricant de moule àseau en plastique en Chine, et vous voulez acheter moule de seau à peinture de haute qualité, bienvenue à me contacter.

Mlle.Ysaline

Whatsapp : +86 138 5763 5311

Skype: sino.pm

Email : export@sinomould.com

With many years’ experience, weare devoting to offering the customer with the multi cavity plastic PET preformmould. Past few years, we have produced from 16 cavity to 72 cavity with our own brand hot runner Anole. More and more customers come to our company for ask about the preform mould project.

Few advantages for our plastic PET preform mould are as below:

1.Material of steel

cavity and core use imported S136 stainless steel with fine polishing, high hardness to get mold's high precision and good quality.

2.About gate

pin valve gate ,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actionon each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

3. About hot runner

hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production ,cavity with lower injection pressure to reduce wear and tear of mould parts. What’smore, we can better offer you the spare parts for the hot runner.

4. Heating system

with double heating system, it has separate temperature control mode ,the heat bar are used to heat the mould mainfold plate,small heaters supply the heating temperature for cavity nozzle continuously.

5.Cooling system

each parts including core ,cavity and valve gate has independently cooling system.

6. Stored spare parts

Each preform mould we have a standard spare parts which can speed up our delivery time to help customer get the profit quickly.

To be the best friend of the customer is what we are pursuing. If you are interested in the plastic PET preform mould, pls come to us for further information.

Martina

Skype: sinomould-17

Email: export@sinomould.com

Phone/What's APP: 0086+15215807221

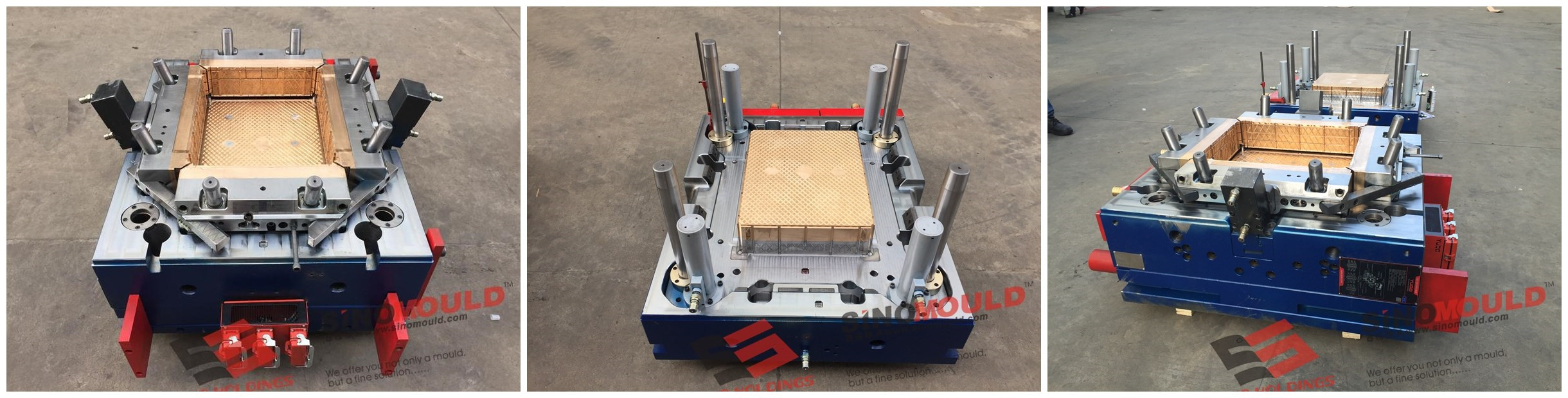

SINO MOULD is professional in making all kinds of plastic crate mould. With many years’experience in plastic crate mould, we have a series of tooling standard for the China plastic crate mould which can reduce the delivery time from 60 days to 40 days, it has attracted many customers come to our company for further information.

I am sure that you must doubt why you can make it so fast. Since the company established,there are several VIP customers will regularly place the orders for the crates, sometime the yearly crate order can reach around 100 sets just for one customer.So with those years’ experience, we can better know which mould steel isbetter, how to arrange the tooling process to save time, which kind of spare parts can be standard to be stored, which cooling system is better, how to avoid the frequent mould problem happened in the daily production…

what’s more,we have establish a special team to make the plastic crate mould, there is noneed for you to worry about the mould deisgn, mould tooling process, mould maintenance.Also we have introduced many famous brand tooling machine form Japan,Italy,Germany.. which can better ensure crate mould precise size.

The customer must be the best teacher who can help you become much stronger. Thanks for all the customers to show their treasure suggestion which help us better improve our technique. If you are interested in the china plastic crate mould,do not hesitate to come to our company, we are devoting to offer each customerwith the best mould quality and service.

Martina

Skype: sinomould-17

Email: export@sinomould.com

Phone/What's APP : 0086+15215807221