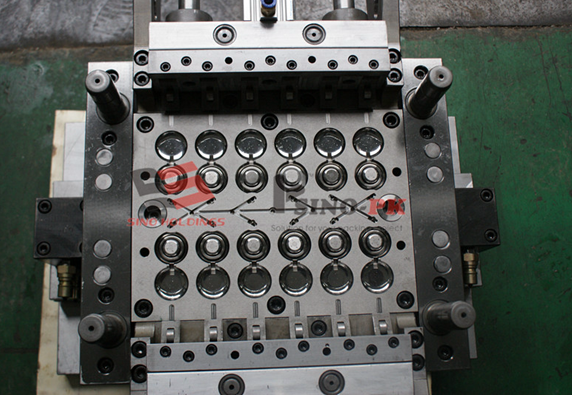

Sino Holdings Group attended Chinaplas 2017 to show our 32cavities PET test tube injection molding line equipment, PET test tube injection machine and 32cavities test tube mould with highly Popularwith the audience.

PET test tube is high precision and with high technically on injection molding, the thickness should be balance and surface by transparent clean, it is need combine high precision test tube mould in precision tooling to controlling tolerancenot over than 0.05mm, also injection machine with high quality injection screw,precision controlling valve, especially for PET material, the screw and longsize should be by accurate calculation. Sino Holdings R&D PET test tubemould and injection machine many years, from 16cavities, 24cavites, and 32cavities PET test tube we can supplying customer injection molding equipmentincluding mould and PET test tube injection machine.

Besides,The other key point of PET test tube injection is the injection molding method,PET is special material the temperature of mould or injection machine have big effecting for PET test tube, so our injection team also have good experience oninjection molding method, with high efficiency production condition. 32cavitiesPET test tube injection machine we choose DAKUMAR 300H high speedinjection molding machine, cycle time 10s, about 12000pcs test tube per hour.

If you are looking for 32cavities PET test tube injection machine supplier ormould supplier, please do not hesitate to contact us, which is first cansupplying turnkey production line solution in China.

Post by:Vivian

Email:export@sinomould.com

What’sup:0086 15858625783

SINO Holdings Group offer customer IML bucket turnkey production line, which included:

1. Painting bucket molds:

S136, DIN1.2344, DIN1.2738, 718H steel material

Inserted with copper-Be

The high and angle of bucket molds interlock system

For high speed cycle time to 18 seconds for 20L bucket mold

2. Injection servo molding machine:

High-performance servo dynamic control system

High speed response

Energy-saving

High-control precision

3. IML label & robots

Environmentally friendly, consist of 100% recycled material

Resistant to mechanical, thermal and chemical effects.

Lower production time

Lower production cost.

in order to increase the output deeply, SINO developed 20L IML bucket turnkey production line with the following injection molding solution.

1. 20L IML bucket mold with BeCu

2. Injection molding machine: DKM-650SV

3. Production capacity: 144pcs/hr

4. Daily production: 3000-4000pcs (3shifts)

5. Yearly production: 1.2million pcs.

SINO offered turnkey project service included:

1. Strong capability with advance tooling equipment from Germany, Sweden, Japan, USA...

2. Excellent service for factory layout design service

3. Offering spot training service in SINO factory for machines operation and basic maintenance.

4. Depute engineer team to your factory for machines installation, help start the mass production for each mould onto their related machine.

5. 24 hours technical support by email, picture, video and if necessary we will send our engineer to your factory to offer spot technical support.

6. Rich experience with over 200 projects in different countries all over the world.

Any inquiry about IML bucket turnkey production line welcome to contact us freely.

posted by Miss Candy

whatsapp: +86 15858685263

skype: anole-hc-02

With 26 years experience in toilet seat cover injection molding, Sino company researched a very good solution to make the mold with the best quality and competitive cost.

Let’s sum up most of the customers’ requirement to the toilet seat cover project:

1. Good steel material: 718H.

Most of the Chinese mold maker will use P20 to make the mold core and cavity, as is known to all, P20 steel is not good enough to make toilet seat cover mold, because the steel quality couldn’t reach real mirror polish standard. It will affect the goods surface glossiness very much.

So except customer have special requirement to the mould steel material, Sino always suggest customer use 718H to make the mold core and cavity.

If customer want to reduce the mold cost, we will suggest 718H to make the cavity, P20 steel make the core parts. To make sure the surface polish affection.

2. Mold life: 500K.

718H steel hardness is better the P20. So it can assure 500K guarantee life at least.

P20 mold life is around 300K. But there are many supplier give false information about the mold life. Professional people will know that, P20 steel is very soft, it is not good for a longer life time.

3. Precision: toilet seat cover injection molding mold worst danger is the flash. Low process precision will cause the mold flash after thousands shots. Good precision must need good equipment to process. A mold with very cheap price, can you believe they will use good machine to make process? No profit, no business.

skype: anole-hc-02

whatsapp: +86 15858685263

email: export@sinomould.com

Crate, a daily used plastic transported container are in big demand quantity in our daily life ,in factories and farm are often used for transportation .which are applied in vegetables and fruits .nowadays ,the crate and plastic container are more and more popular,so there are big quantity request of crates .and more and more investor are focus on new project .develop crate production line to make more and more crate for market request.

Then how to make a high quality crate mould molding ,running many years without bigproblem . this is very important for plastic field plant.

First of all , the crate mould injection system should be designed easy and perfect coolingsystem . meanwhile , fast flow for crate mould .

2ndly ,Refer the crate molding ,the demolding is very key points for crate mould.we need to make good and suitabledraft angle for ejection . so it will demould easily from the machine .

3rdly.Select good qualtiy and suitable steel material prettt important for the key point to make high quality of crate mould . for example .we use Din1.2738 to make the crate mould ,the hardness we will make it with HRC32-36 , the mold life of the crate mould can be about 1 millonshots . usually , the crate mould can running more than 5 years .,if choose P20 and 718H steel material . the mould life will be 500K at least .

Please feel free to send your new project to us ,we will offer you fine solution for your new crate molds and crate molding machine projects .

Postedby Selinda

Whatsapp:008615858629913

E-mail:export@sinomould.com

Skype:sinogroupe-selinda

Sino Mould are specialized in making all kindsof paint bucket ,ranges from 1liter to 25 liters .the shape can be round andsquare paint bucket mould . we can make it single cavity and two cavity bucketmould.Dakumar are another branch company of SINO HOLDINGS GORUP,we are aimed atoffering the bucket molding machine ,offering the whole turnkey paint bucket production lineto all clients worldwide .

SINO owns rich experienced mould designer technical engineer . who are capable of making the paint bucket with one cavityand two cavities including the injection system ,perfect cooling system andrecommend our suitable tonnage of injection molding machine to our customers .

There are many mould features of the bucket mould we made .

Before we making the paint bucket mould ,weusually make part and mould analysis .

To analyze the material and the bucket structure is good or not ,if not good ,we will make improvement .

We apply the advanced hot runner system,Anolehot runner system ,with German heating elements .

Perfect cooling system of bucket design ,canensure the bucket fast cycle time .

Good quality and suitable Mould steel ,themould steel are hardened and heatment .can guarantee bucket mould lifetime morethan 500K by use 718H .

We aimed at making top quality bucket molding line for customers from different market. We have make 1L bucket mould ,2L bucket mould,5L bucketmould,10L bucket mould,15L bucket mould,20Lbucket mould,Sino is a professional bucket mould maker in Huangyan ,China . if you have any new project on paint bucket mould .welcome to contact me .

Posted by Selinda

Whatsapp:008615858629913

E-mail: export@sinomould.com

Skype:sinogroupe-selinda

Chinese famous mold manufacturer SINO isprofessional in making unscrewing flip top cap molds with more than 20 yearexperience. Compare to stripper flip top cap mold, unscrewing cap mold ensurethe cap has good mounting on bottle.

Unscrewing flip top closure mold features:

1. In order to achieve the unscrewing system, wehave product designers to check clients flip top cap, such as, cap screw needstart from the flat surface. Besides, we will check whether the flip top capand mounted bottle has interference or not.

2. We adopt hydraulic motor or hydraulic cylindersystem for unscrewing system. Our designers will make mold design based on fliptop cap mold cavity and its structure to make sure unscrewing system can runsmoothly.

3. For mold core and cavity steel, we adoptimported Assab S136 with HRC 42-44, mold guaranteed life will be over 5M shots.

4. Hot runner is designed advanced andreasonably. Each cavity heat controlled independently, temperature uniform.

5. Each cavity and core have independent coolingsystem, shorten production period.

6. Each cavity is self-locked, can be changed conveniently.

Any question regarding to unscrewing flip top closure molds, please feel free to contact me.

Post by Miss Mandy

Email: export@sinomould.com

Whatsapp: 008615757610702

Diamond cup, one of the popular cup projectin the world plastic injection molding trade, like an artwork, it have becomeshining appearance showing in front of everyone.

In 2016 Chinaplas, Sino Holdings Groupshowed a diamond cup production line for clients all over the world, with ourhigh speed injection molding machine and high speed robot for picking upproducts from the mold. Now let me introduce about that:

1.diamond cup mold

Our diamond cup mold is four cavity with S136steel material. High requirement of parting line and surface dealing is requiredduring the production. Now avoid the steel cracking problem, we also reduce thesteel hardness to 40-44 HRC.

2.200HH high speed injectionmolding machine

In exhibition, we use 200HH high speedinjection molding machine for high speed production. The cycle time could reach3-5 second, achieve our high speed injection for plastic cup molding.

3.Side CNC robot(side enter robot)

With side CNC robot, we could help clientsto achieve all plastic injection molding line automatically. No labor cost inthe production, which will be more efficiency and safety in daily production.

We also offer some auxiliary engine, suchas autoloader, chiller, air compressor, belt conveyor and so on.

If there is any interest, welcome tocontact me.

Snow

export@sinomould.com

SINO MOULD Co., Ltd is the world famous Foldable Pallet Box manufacturers in the Southeast of China, from 2000 small workshop till today, SINO MOULD.

SHG is a leading foldable agriculturalcrates& pallet box manufacturer company in china, focusing on the suppliersof folding pallet box, crates containers, collapsible crates & boxes etc.

SHG is a leading foldable agriculturalcrates& pallet box manufacturer company in china, focusing on the suppliersof folding pallet box, crates containers, collapsible crates & boxes etc.

There is a great demand for Pallet box in themarket today. These are boxes which can be folded material like heavymachinery, higher and medical imaging devices. X-ray machines, food items,medical and any other things can be safety and securely delivered to anylocation without the issue of the item breaking or getting a problem due totransport visit our site.

Simple package, security economical for all thecustomers, we have more than 17 versions of foldable crates, from 400*300*150mmto 800*600*450mm. we can also design the size or pattern as per for your ideasand drawing and colorful.

Every process is under strict control, fineworkmanship and skilled craft. Lots of

Advanced equipment make every process perfectand functional.

Foldable crates use high-glass injectionmolding to manufacture the mold, this will make high quality are reasonableprice, smooth surface, strength construct, colorful crates, simple design, easyto take and carry. The last, not the least, this crate is collapsible, whichallows easy storage.

Also, plastic foldable storage crate arestackable, which give you the freedom to make the best of available space. Wemake it suitable for enterprise & shipping transportation, after folding,crate capacity is 1/5 of unfolding crate, this will benefit for our customers.

If you have any demand for Foldable Pallet Box, pls feel free to contact Miss Nancy.

Email: export@sinomould.com

Skype: sinomould-01

WhatsApp:008613758679372

There are many cap mold supplier in China.But really only a few will be well-known with the plastic injection cap mold.Nowadays, the cap should meet bellow requirement :

1.Enviromentally friendly:

Reduced plastic resin consumptions for thePET bottle (net ) for the closure.

2.Improved carbon foot print:

Less green house gas emississions per litreof water delivered to end consumers.

3.Uniquerange:

Of light weight closurers for new lightweight PET neck standards for water(18,28,38)and screw and sports caps.

4.Reliable capping performance

Even on high speed filling lines

5.Packaging performance

Similar to better than existing closuresfor still water: tightness, organolepticiy, tamper evidence, comfort to openand reclose

6.Economical

Significant contribution to reduce theeffects of polymer price and transportation cost increases.

Sinomould company, specialize indifferent kinds of plastic packing mould, such as 28mm standard cap, 38mmstandard cap, 48mm standard cap, flip-top cap,5gallon cap mould and otherdifferent types mould. As a best- known plastic injection mould supplier, wehave professional design team and tool maker expert to make different kinds of plastic injection mould.

Any other question, please feel free tocontact me.

Posted by Snow

Email: export@sinomould.com

Skype:sinogroupe-71

Plastic chair injection molding solution is very important to a chair manufacturer. It will affect the chair load, weight, cost, output, etc. a reasonable chair design and mold design will help customer save cost and hot selling.

A few days ago, we have a customer bring a chair sample to ask SINO to modify the samples. He want to increase the seat load and back load, same weight. After checked customer’s chair sample, we found the chair design is not good. When it load with 60kg, the legs put aside, and when it load 100kgs, the legs deformed seriously.

Nowadays, the fatter people becomes more and more. So it a chair only can contain weight with 60kg. We could know that the market will reduce substantially. After meeting with SINO experienced engineers, the preliminary design was finished. The weight is same. But it can load 150kg without legs deformation. And we increase the back load weight to 45kg.

So you will find, with the same devote, SINO will offer you a better Plastic chair injection molding solution. That’s the reason why we have too many customers and orders. Strength proves everything. SINO GROUP welcome your visiting.

Sales engineer: Candy

email: export@sinomould.com

Skype: anole-hc-02

whatsapp & wechat & viber: +86 15858685263

Electric fan plastic parts production line supplier, Sino Holdings has offered 710 plastic injection molding production lines to more than 100 countries. We will tailor the most suitable solution for your new business.

First, SINO can support you with budget and analysis for your production cost, and give you most reasonable design of plant segment.

Second, SINO will offer all Electric fan plastic parts production line drawings and NECESSARY equipment list. And according to the sales and service contract, we give you all the equipment that needed to build up your plant. Upon ready delivery in SINO, we will give you all the best quality and you can come to see the turnkey plant running in SINO before shipping.

in summary, SINO will offer you injection machine selection, molds with high uniform to machines, auxiliary equipment for machines and plant, mold maintenance equipment & spare parts service, raw material selection & purchase and electronical elements for plant.

Third, SINO give one year warranty and all life time service for engineering, training to you and prompt after sales service, as well as new project development suggestion.

Last but not the least, in order to make much understanding of your electric fan plastic parts production line, please fill our investigation list and when necessary, SINO will send engineers before plant set up, for measuring, drawing and analysis the floor foundation, and power condition.

Sales engineer: Candy Wang

Email: export@sinomould.com

Skype: anole-hc-02

Whatsapp & wechat & viber: +86 15858685263

SINO HOLDINGS GROUP is offering plastic Grass Cutter Injection Equipment including injection machine and grass cutter plastic mould with good experiences.

To become China best supplier for plasticinjection molding equipment, we had offered many turnkey project for plasticparts, such as auto parts, home appliance parts, industrial parts, domesticappliance, Plastic Grass cutter injection mould and injection machine supplyingto Spain, Brazil, and Mexico etc…

Grass cutter plastic parts should by strictdimensional requirements for good assembly and surface, how to control thegrass cutter dimensions is depend on high quality grass cutter mould, and technicianfor injection parameter adjustment. SINO team tooling machine for mould by DMG,FADIA with high precision to ensure mould and parts in exactly dimensions. Moulddesign with good cooling system for reduce cycle time, increase productioncapacity.

Injection molding machine brand Dakumar Machinery can produce machine 50Ton to 4000ton, with famous brand machine componentsfor electrical and hydraulic, bring your high quality and stable machine also service.

Another component of grass cutter injectionequipment is injection molding machine and injection auxiliary equipment, assuch chiller, loader, dryer or crusher for recycle plastic material. We have make design and Choose suitable machine for grass cutter part mould, can givesuitable solution for production, including plant design, part & moulddesign, mould & machine test, installation, training etc.. Service, it’s convenientand easy for customer investment or extend factory.

We sincerely welcome you can down visit us,if you have any questions about Grass Cutter Injection Equipment please feel freeto contact us.

Post by: Vivian

Email: export@sinomould.com

What's up: 0086 15858625783