To ensure high standard and good quality plastic thin wall molds, palstic IML mold design, plastic IML mold tooling technology and so on are very improtant. But basicly thin wall mold steel selection is also very cruical, just like basic foundation of skyscraper.

As known that plastic thin wall IML molds usually require high speed production. So on thin wall IML mold steel selection, we strongly recommodate our customers to choose DIN 2344 or Stavax S420 for thin wall IML mold cavity and mold cores.

But why we need thin wall IML mold steel with HRC42-45 for mold cavity and mold core?

4.If with higher hardness than HRC 52, it would be difficult to tooling, for instance difficult cnc millding and lath tooling

We are home appliance plastic mould maker for making different kinds of the injection moulds, our company cooperate with Germany company, catching the technology of plastic injection molds, with mature injection molding and senior designers & engineers, all the customers are satisfied with our plastic injection moulds. Annual about 2,000 sets plastic injection molds export to all over the world, which leads us becoming an outstanding plastic injection mould, especially, home appliance plastic mould.

We are famous for home appliance plastic mould, such as: chair mould& table mould, kitchen mould: fork mould & spoon mould & knife mould, bowl mould, cup mould, airline cup mould, food container mould& IML system solution…all these with high technology and advance injection molding machines to manufacture the home appliance plastic mould, not only the mould, but also the injection molding machines.

we will offer you the whole production line. Regarding the after sales services, we have a 24 hour team online, can troubleshoot your questions on time.

If you are also interested in our home appliance plastic mould, pls feel free to contact me.

Posted by Miss Stephanie

E-mail:export@sinomould.com

Skype: sinomould-15

Our company is professional at plastic injection molds, which was established in year 2000. Such as home appliance mould, we use P20, S136, DIN.1.2344 ect for normal plastic home appliance products, DIN1.2344 made in THYSEN German, with HRC 42-55, Nitrited with HRC 60. DIN 2311 made in German, with HRC33-36 and H13, S136 these steels need to be quenched and Nitrite treatment on the surface before they are making the rough machining. They are all stainless steels and resistant to corrosion suit for PVC pipe fitting moulds,, besides, they are toughness, high mirror suit for car light and transparent packaging moulds.

Different kinds of plastic mould steel get their own feature, once our customers place the order to us, we will use the suitable plastic mould steel as per the plastic product purpose. Our company has more than 20 years mould experience from now on.

With high technology of the injection mold and advance injection molding machines, we are becoming the top plastic mould manufacturer in China.

Sino will offer you a high quality mold and a whole production line.

Welcome your visit to our website: http://www.sinomould.com

Posted by Miss Tina

E-mail:export@sinomould.com

Skype:anole-01

The molding temperature control system is a very important factor in injection moulddesign .The injection molding means mould acts as the heat exchanger to make 200℃ plastic melt cool to finalize.The molding temperature control system will make an impact on the injection mould quality and the production efficiency . The mould temperature demand depends on the type of plastic raw material and the quality of plastic parts . If the molding temperature is above 80℃,the heating system should be set .

The following are what molding temperature control system influence on :

The quality of plastic products ,including the dimensional accuracy, shape accuracy,mechanical property ,surface quality .

The productivity,it is 2/3 of the total injection cycle time.Shortening the cooling time is the key improvement of productivity.

In order to improve the efficiency of the cooling system and the cavity surface's temperature uniform distribution ,cooling system should be designed as follows :

The layout of cooling system should be considered earlier than the demould mechanism.

Ensure the center distance of the cooling pipe and the distance between cooling pipe and cavity wall.

Lower the temperature difference of water in and out .

Strengthen the cooling efficiency upon the gate.

Cooling channels shouldn't be set on the weld line.

The SINOMOULD CO,LTD is a famous china injection mould manufacturer and innovator .we are dedicated to the injection mould design ,injection mould manufacture,injection mould innovating.If there is anything we can do for you , please contact me ,Miss MAY.

Moulds are easy to be frayed when they have been used more time. But if we neglect to reparation of moulds, it will bring about a lot of losses.

We can change the damaged components according to the drawing.As for the damaged cavities which have not been quenched, we can repair by adopting copper brazing or partial mosaic. Otherwise, we can mend it by epoxy resin.

For the dermatoglyph surface, we should repair it by adopting special process. For example, we can repair the damaged surface by using plastic sheets of steel materials and then precede partial corrosion.

If the parting surface is not rigorous enough or with much overflow, so we can rubdown the surface and then process the cavity to the original deep.

In general, mould which has been used for a long time, we should examine the fastening degree of the fixed components and positioning cylindrical pin. If necessary, we should fasten them again so as to avoid the position migration of the components. If serious, it will influence the precision and quality of the mould.

After the mould has been used for a long time, we should polish the cavities and cores at regular intervals. It can be beneficial to keep original rough degree and avoid the quality reduction of the mould surface. If possible, we can make the cavity polished and chromed which can help the quality of the mould surface the good result of the overhauling.

The components which cannot be repaired, we’d better renew them.

If we want to keep the moulds in good condition or reduce the time of reparation of moulds, we’d better check it at regular intervals.

China biggest chair mould supplier, we offering garden furniture moulds, arm chair mould, PC chairs, PC chair design and moulds, armless chair moulds chinese maker, gas assistant chair moulds, table moulds, high precision chair moulds.

SINO MOULD is very specialized in garden furniture moulds, such as arm chair mould, PC chairs, PC chair design and moulds, armless chair moulds chinese maker, gas assistant chair moulds, table moulds, high precision chair moulds with our strong mould design and analysis ability, we can avoid welding line, cold material mark for PC chairs, and defect of injection molding PC chair. We have made chairs in various excellent design, such as rattan net design, gas assistant rattan chairs, glass looking chair moulds, rattan tables in round table, square table for 4 people and for 6 people, big plastic table and plastic chair mould molding.

Welcome your enquiry for plastic chair and table molding line, we will offer you best solution for high quantity production line for plastic chair and plastic table molding turnkey solution.

Contact us for more detail for moulds making or plastic molding products.

export@sinomould.com

export@sinomould.com

skype: sinomould.dakumar2

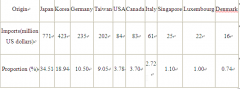

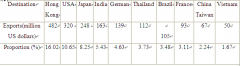

2011 China’s mold import and export amounted to 5.24 billion US dollars, an increase of 23.06% compared with 2010. The total value of import has reached 2235 million US dollars, increasing by 8.37% than last year, while the export has reached 3005 million US dollars with a 36.87% increase over 2011.

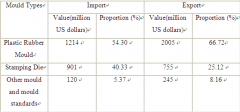

Firstly, according to different types of mold, the import and export of plastic rubber mold ranks first, covering respectively 54.30% and 66.72% of the total value. Stamping mold came in second place. Below are the details.

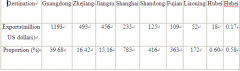

Fourthly, according to the export origin, most of molds exported are from Guangdong, Zhejiang, and Jiangsu. Below are the details.

If you need more information about China injection mould, please contact us.

Edited by Cina Zhu

E-mail: export@sinomould.com

Skype: sinomould-13

MSN: export@sinomould.com

Mould modern industry is important process equipment, is many industrial products production indispensable component.

The type of mould is usually according to the different objects and technology processing classification, from the Angle of the industry to distinguish between main plastic mould, rubber mould, BMC mould, die costing mould and so on mould.

Here is introducing plastic mould. According to the molding method is different, can be divide different technical requirement of plastic moulds type: basically have injection molding and extrusion molding, die costing mould, blowing molding mould, and foam molding, etc.

Injection molding is the most common used in the production of a kind of molding, the processing equipment is plastic injection molding machine.

With the injection molding process production of plastic products is very wide, from life commodity to all kinds of complex mechanical, electrical appliances, automotive parts and so on, it is plastic products production in the most widely used a processing method

Plastic blow molding mould: is used for forming plastic containers kind of hollow products (such as water bottles, cosmetic products and other various packaging container) a mold

Plastic extrusion mould: is used for molding production of plastic products shape continuous a kind of mold, widely used in tubes, rods, monofilament, plank, thin films, wire and cable coated layer, profiles of the processing.

Also our Sino holding Company produce mould and injection machine. If you need any require and help, can send E-mail: export@sinomould.com to me.

Post by: Ophelia

Sales engineer

E-mail: export@sinomould.com

Skype: sinomould-10

MSN: export@sinomould.com

Dual-color injection molding is always widely used in toothbrushes, cups, and bottle caps and any other daily necessities. The so called dual-color molds refer to two kinds of plastic material in the double color injection molding machine, then they will need two molding, but only one mould unloading.

Option of two kinds of raw material

Choice of the gate location

Choice of the double color mould

Distributor of bulk crate mold and bulk container

SINO MOULD offering our customer with nestable containers mold manufacture from China, stack nest containers chinese supplier, foldable large containers collapsible crate in foldable design, storage tray and modular bins China, beverage crates and logistic bulk pallet, bottle crate with pallet moulds, folding crate mould and bulk folding crate pallet, tray mould in large size.

bulk container mould

We give our bulk crate buyer with bulk crate design, bulk crate mould design, tooling and bulk crate injection molding service. standard & custom bulk reusable containers. Types of containers include collapsible containers, foldable container boxes, totes, cases, crates, sleeves, trays & reusable bulk containers. Crates such as fully enclosed crates, reusable crates, slat crates & trade show crates are available.

Contact us for more detail for moulds making or plastic molding products.

export@sinomould.com

export@sinomould.com

skype:![]() sinomould.dakumar2

sinomould.dakumar2

We are professional in medical dustbin manufacturer in China, medical wastbin, medical waste container, medical trash bin etc…

Medical dustbin should be enough wall thickness to avoid if there have liquid of medical outflow, to avoid pollution; Usually Medical dustbin is convenience for discard dustbin, Medical dustbin will make disposable cover with high seal; convenience for transportation; transportation for stock.

About the medical dustbin mould will be high precise dimensions with high precise tooling, usually will be high speed CNC, SODICK EDM,etc..; and medical dustbin choose steel like 2311,2738,718H , medical dustbin mass-production,usually the mould life will be 1000K.

Our company is specialized in plastic mould, which located in Huangyan city, people called it “the town of plastic mould.”We are tool box mould exporter, tool box mould maker and tool box mould supplier, besides, we are a customizing manufacturers of tool box mould.

Our company is good at tool box mould. We have a professional team in making tool box mould and 24h online services of troubleshooting of tool box mould.

We adopt special injection molding of tool box mould , increase intensity of tool box mould, clear surface of tool box mould easy to wipe the greasy oil , tool boxer handle use soft rubble injection moulding , which express the humanity.

The size of the tool box mould depend on customers request, tool box is convenient to carry in the car trunk.

The four corner of tool box material with crash proof.

If you are interested in our tool box mould, please feel free to contact me.

Welcome to download our website: http://www.sinomould.com

Posted by Stephanie![]() : sinomould-15

: sinomould-15

E-mail: export@sinomould.com