China is the hometown of plastic mould, we are famous for making the plastic household mould. Sino mould is well known by worldwide customers, they are familiar with Sino mould, they know we are professional household molds supplier, the china plastic food basket mould is the hot item of our company, many customers are would like to make this kind of mould ,so now we have the abundant experience to make the china plastic food basket mould.

From prepare the mould steel to the first mould testing ,we only need 55 days ,and the quality is guaranteed, we have the individual designing team who have designed many types plastic basket mould ,so we could offer you the simplest mould construction and optimized cooling way, the cycle time is short than other company.

China plastic food basket mould, you could orderMold Plastic Parts from SINO ,no matter what requirement you want ,I am sure we could consider all the aspects for you and make a tailor solution for you.

Any interesting ,pls do not hesitate to contact me.

Sino Mould is the Chinese die casting molding maker, we are famous in this line. Now, we have introduced many new technologies to improve the quality of die casting mould. Many customer come to us ,ask for costuming the die casting mould from us, some for the automotive parts, some for gas equipment and lamp, etc.

The die casting mould need high standard tooling machine as it is the high precision mould, we have brought many sets machine from Italy, Germany, etc.

We have made many sets alloy die casting mould and offer the die casting molding service. Which is help many customer without the full die casting processing equipment and want to get the help from us. We offer the production, packing, shipping and well after-sales service. As the die casting plastic mould quality is so important, as the high pressure inject to the die casting mould, which is higher than the injection mould, and the temperature of the liquated alloy die casting is very high, we know the dangerous situation will cause the serious problems. So we are strictly control the die casting mould quality, such as do the flat and closed mould parting line and choose harden mould steel .

If you want to make the die casting ,pls contact the professional Chinese die casting mould maker, who can guarantee the quality ,the safety .Come to us ,contact me!

12 cavityspray cap mould

Sino-PK had achieved a great success in makingspray cap moulds, recently we had tested the 12 cavity spray cap mould and

a tiny insert successfully. The tiny insert diameter is only 5mm, the following is the tiny insert mould specification:

1. mould cavity: 32 cavity

2. cold runner

3. mould steel: H718

4. cycle time: 7s

5. insert diameter: 5mm

Sino-PK Co., Ltd is very professional at design and manufacturing plastic package mould, we believe Sino is your good partner

for your preform, cap moulds.

Post by: Rita email:export@sinomould.com skype: sino.group06

Take the advantages of buy good moulds and machines together as a turnkey project solution.Do you understand the advantages of order molds and machines at one time?order good moulds and machines,buy mould and machine together.

Buy moulds and machines in turnkey project solutio, can make your easily handling of your purchase of custom turnkey project with molds and machines.

* Quick delivery of all goods together which can also avoid arguing between different suppliers for molds and machines.

*Clear responsibility of whole project if you buy moulds and machines together from one good turnkey project supplier.

*Fast response for your doubt, because we can offer you answer upon recieving your email.

* Strong design ability and uniformity which is very easy for your future handling of moulds and machines together.

*Less cost for paying service, you need only to pay one time engineer from us, and can get service for your bought moulds and machines.

* profit in very short time for the turnkey project of moulds and machines together.

*Easy QC control & inspection because you come only one time and easily cooperation with good buy moulds and machines supplier.

* prompt after-sales service from us after you buy good moulds and machines together.

Get your enqiury for turnkey project, and we will send you our best offer for good moulds and machines together.

Contact Fancy: export@sinomould.com

skype: sinomould.dakumar2

Sino Mold Making is the professional processing,has the strong mold making teams equiped with precision molding making machine and mold design teams. The mold making machining process are the most advanced.

Mold Making Mentalities

Mold Making Mentalities a

re the most important, it is because the mold making 1st step is plastic parts' model analyziz and mold design. If there is no deep analysing to the plastic part design, if the mold design is not good enough. How can we do a good mold making?

Mold Making Technologies

Mold making technologies are included mold design, it is came from mold making experience and the understanding to mechanical, the knowledges to steel and plastic.

Mold Making Machines

After the correct mold designed, we need precise mold making machines and equipments to do all the components according to their dimension tolerance. To do all the molding line, curve and corners accurate.

Mold Making Dimension Controlling

The precision mold making machine, and correct machining process can not guarantee 100% dimension correct. We need strong controlling to any tooling result to be sure that all the machining results are within tolerance.

Mold Making Mass Production Simulation

When the molds components was assembled, it is not meaning that we have finished the mold making, we need to run the mold on the molding machine to be sure that the molds are suitable for high speed injection molding and stable dimesion molded plastic parts. After long time running, if there is none damage and none other problems, then we can say we have finished this mold making.

Injection Molding Machine,injection molding machine china,injection molding machine manufacturer,Dakumar Injection Molding Machines is the qualified injection molding machine supplier in China.

DakumarInjection Molding Machine has delivered 485 sets to oversea from Jan 1 to Oct. 10 of 2011. Hopeful in 2011 year, more than 600 sets of injection molding machines are able to be delivered.

Sino Holdings Groupinjection molding machine producing and service has became the group's another developments emphasis, Sino Holdings Group are considering to invest more than 20M USD for new tooling machines and RND centers for injection molding machine manufacturing and developing.

Injection Molding machine's developing planning for DAKUMAR is as below:

Keen on developing the energy saving injection molding machine. Heating energy saving nd actions energy saving.

Keen on high speed injection molding machine developing.

Keen on machine precise injection molding.

Developing for huge clamping force injection molding machine such like the machine bigger than 2000TON.

In order to produce high precision injection molding machine, Sino Holdings Group invested a lot of tooling machines to make all the mechanical components high precise, based on the strong frame and stable high re-action controlling system, high precised mechanical components guarantee high speed injection molding.

Due to the large tonnage injection molding machine production, Sino Holdings Group invested an huge workshop which the floor can loan and the crane can lift more than 150TON weight of machine or parts group.

DakumarInjection Molding Machine is now growing very fast, this injection molding machine brand has a very brilliant future. Injection Molding Machine for high speed, injection molding machine stable and energy saving.

Offer Pipe fitting mould in China. As Chinese top pipe fitting mould supplier and manufacturer, Sino will give customer best pipe fitting mould with good quality, pipe fitting molding, and online pipe fitting mould service.

Sino offer customer a whole pipe fitting mould solution which contains PVC pipe fitting mould, CPVC pipe fitting mould, UPVC pipe fitting mould, PVC belling pipe fitting mould, Electricity cable pipe fitting mould, PPR pipe fitting mould, PPR pipe fitting mold, PPR pipe fitting mould unscrewing ejection, PPR metal over molding pipe fitting mould PP pipe fitting mould , and PP belling pipe fitting mould and so on.

We also can offer customer CPVC pipe fitting mould for high pressure and UPVC pipe fitting mould for water drainage. With mature tooling experience, pipe fitting mould design and every step of pipe fitting mould tooling is under our control.

Sino will always give customer pipe fitting mould with good quality.

Pipe fitting mould, pipe fitting mold, pipe fitting molding, pipe fitting mould manufacturer, pipe fitting mold supplier, online pipe fitting mould service

Posted by Vera

skype: sinogroup-vera

Full Service Plastic Injection Molding Company

We provide high capacity, fast turnaround production of Injection molded plastic parts and custom designed molds from our state-of-the-art injection molding facility.

From Design to Delivery

We offer the capacity to take your concept from initial prototype all the way through final decorating, assembly and packaging. And we'll deliver to meet your marketing needs or your "zero inventory" assembly schedule.

Why we choose plastic bulk crate? As by wooden crate or carton box, it has relative limitations in some specific area. Compared to original packaging, plastic bulk crate stands out of its anti-corrosion, moisture, impact resistance. And collapsible bulk box is prominent among it.

Collapsible bulk crateadvantage:

Recycle using

Easy to use, save effective space

High strength, special engineering plastics used

Lower transporting cost when crate empty

Clear by water, keep appearance beautiful

Less weight than original packing

Useful life much longer than by original packing

Crate body with pallet bottom base, much convenience for transporting

We supply folding bulk cratefrom small size to larest size 1200*1000*1000mm to meet different needs, if you have any interest, feel free to contact me.

Ms Tina

Mail: export@sinomould.com

Overmolding injection technical is an over molding technologies which discribed different material over molding process,this topic talked overmolding injection keypoint.

Overmolding injection technical is the injection process for two or more type of differnt plastic material jointed during their melting after they were filled into the molds cavities.

Overmolded plastic components are such like, tooth brush, kids care products, pnuematic tools handle, car lighting system (tail lamps lense).

Overmolding processing has two kinds of way.

the different materials or different colors were jointed by out of the mold, this meaning, one molded ready one of the part can put it into an other mold for second or third material (colors) injection.

the multi-material or multi-colors injection molding and jointing inside of one mould and done by one machine.

The 2nd processing of overmolding injection has two types.

One is by the injection molding machine's clamping plate rotary.

The other is by the injection molds' inside medical action to realize the 2nd material injection filling and jointing.

Overmolding injection mold and machines are high precise and high technologies requirement. SinoMould offers turnkey project for machines and various of molds, also help our customer to run the machine in their workshop.

POST byMiss Marryfrom Sino Holdings Group.

export@sinomould.com / export@sinomould.com

Skype:sinomould-06

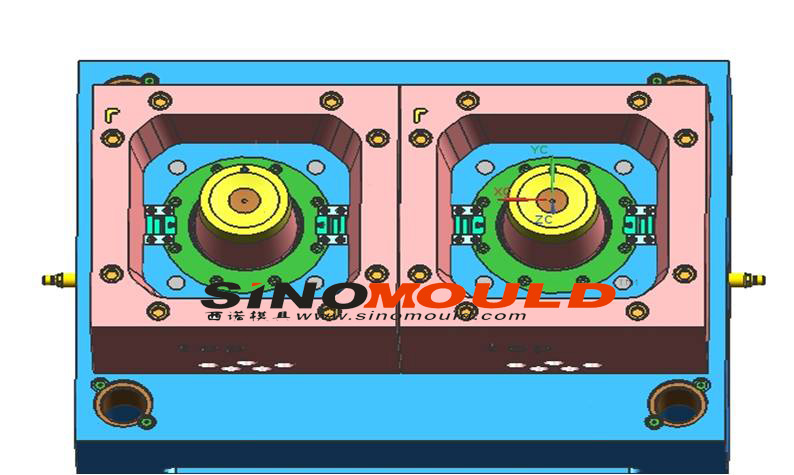

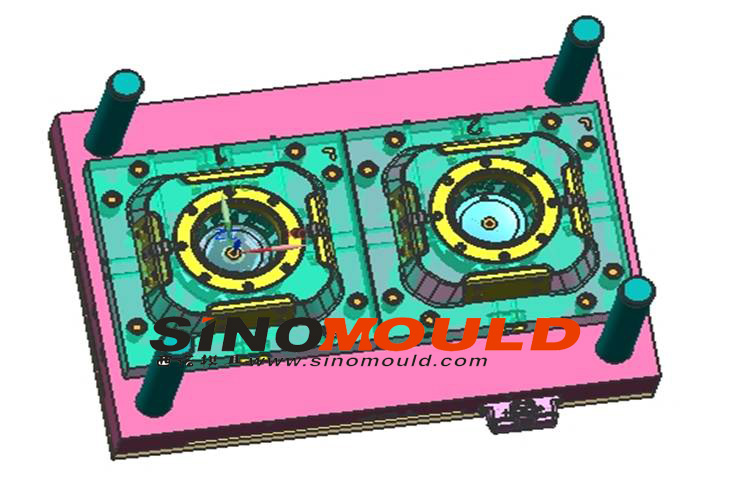

Sino Mould can offer high quality food container mould for different size and shape. For the shape, we can make both square and round shape food container mould. For the size, we can make food container mould for 100ml, 200ml, 300ml…500ml, 1L, 2L, etc.. For cavity, number, we can make 1 cavity, 2 cavities, 4 cavities and even 6 cavities according to different size and structure.

Sino doesn’t only offer food container mould, but also offer IML solution for food container mould as we as injection machine and robot for food container production line.

Looking for food container mould, please contact me.

Miss Cina

Skype: sinomould-13

E-mail: export@sinomould.com

buy plastic machinery parts mould

Buy plastic machinery parts mould from China, come to SINO MOULD. Our company has made different kinds plastic machinery parts mould, we have very rich experiences.

SINO is a very famous injection mould supplier in China, offering high quality plastic injection mouldand fast delivery injection mould for many years. We have made many plastic machinery parts moulds before which are widely used in different areas. SINO MOULD has our own design department which could provide well product design and mould design for you.

If you would like to order buy plastic machinery parts mould or custom plastic machinery parts mould also plastic factory equipments come to SINO MOULD.

Tina

export@sinomould.com

high quality plastic injection mould company,offer fast delivery injection mold,famous injection mould supplier in China,high classic plastic injection mould,custom plastic machinery parts mould