Thinwall injection mould technology with IML system is warm welcomed in plastic molding filed. Sino Mould is one of the greatest thinwall Container mold suppliers in china, professional for thinwall container mould, multi-cavities high speed injection mould, can offer you whole IML solutions(IML robot system, high speed injection molding machine and thinwall container mould,lables)

All the equipments for IML system as follows:

• Injection Mould

I-M-L Mould Application

Flower pot.

Sino Mould have very strong confidence to make you well satisfied!

Send me Email to export@sinomould.com or export@sinomould.com

Or click  to start online service, if it not use please contact skype:sino.group03

to start online service, if it not use please contact skype:sino.group03

Contact:Charlene

Do you have the question where to find a good mould manufaturer, and how to get there?

Huangyan Mould industrial is your best chooice!

Sino Mould is a corporation specialized in producing plastic mould and processing the big and medium-sized plastics pieces.It's located in Huangyan -the hometown of mould and delicious orange of China.The city transportation is very convenient,we are near the super highway,only 20 kilometers from Huangyan airport........You can come by air, if you near Shanghai,Ningbo, you can also come by train.

Huangyan mould industrial,good mould manufaturer,mould hometown,huangyan mould company,best mould supplier china

If you need help to get there, Huangyan -the hometown of mould, please feel free to contact me,

i will help you to find a suitable mould supplier!

Contact:Tina

Email:export@sinomould.com

China biggest crate supplier

Email: export@sinomould.com

Skype: sino-mould-08

SINO HOLDINGS has our own mould company,machine company and hot runner company,could offer you well solution for setting up a new plastic factory and fine plastic molding solution.

1.Rent a spacious factory

The factory should be suitable for plastic injection, its lateral area should be big enough to put inejction machine, plastic material and maybe some molded products.

2. production equipments

Necessary plastic production equipments will include plastic injection machine, some auxiliary equipments (auto loader, water chiller, hopper dryer, air compressor, crusher, mixer etc. ), plastic injection mould

3. Well water resource and electricity distribution

4.Experienced machine operator and mould technical people

The machine operaotor should know well to run the machine and familiar with some problem happen on the parts molding. And the mould technical people should have the ability to solve some mould problems.

It is very important to choose a reliable mould and machine supplier. Our company is a holding property company, we have below several branch companies:

SINO MOULD CO.,LTD offer high quality plastic injectiuon mould.

DAKUMAR MACHINERY CO.,LTD offer high cost performance plastic injection molding machine.

ANOLE HOT RUNNER is specialized in hot runner technology, could offer you fine solution for hot runner molding solution.

Tina

export@sinomould.com

Crate mould classification

Below content is the simple classification for crate and crate mould:

Bottle crate mould

Vegetable crate mould

Fruit crate mould

Sea food crate mould

Bread crate mould

Milk bottle crate mould

SINO MOULD 4 cavities crate mould design have been updated many times, it is suitable for high speed injection moulding, e.g. crate size 400*300*160mm, moldmax in the moulding area, the injection speed can approach 32 seconds. Come please, we are the profesional.

If you are interested in our product, welcome contact us for quotation.

Latest crate molding technology,famoudl crate mould manufacturer,professional crate mold company ,latest crate molding technology,highly cost effective crate mould.

export@sinomould.com

whatsapp:008615167663781

This article is mainly talking about Huangyan airline cups 4 cavities molds,Huangyan airline cups 4 cavities molds,Huangyan airline cups 4 cavities molds design,Huangyan airline cups 4 cavities molds material,Huangyan airline cups 4 cavities molds tooling,Huangyan airline cups 4 cavities molds technical information,Huangyan airline cups 4 cavities molds technology,Huangyan airline cups 4 cavities molds manufacturing,Huangyan airline cups 4 cavities molds tooling,Huangyan airline cups 4 cavities molds making,Huangyan airline cups 4 cavities molds supplyer .

Huangyan airline cups 4 cavities molds design We have our design team and R&D design department, so we have top design

mentality to design Huangyan airline cups 4 cavities molds. We wil make Huangyan airline cups 4 cavities molds mold-flow analysis to make sure the

optimize injection system and cooling system.

Huangyan airline cups 4 cavities molds material

Huangyan airline cups 4 cavities molds , usually we use S136 or Din1.2316,or better Din1.2083,So to make sure the mold can be with long service life.

Huangyan airline cups 4 cavities molds making

We make Huangyan airline cups 4 cavities molds through 3 stage.First,CNC rough tooling, we will leave some tolearance for precision milling in this stage. After rough tooling, we will make heat treatment to get the Huangyan airline cups 4 cavities molds with higher hardness to longer the mould service life. After heat treatment, the mould dimension will change a little and also the shape, so we will use Italy imported FIDIA high speed milling machine to tooling

theHuangyan airline cups 4 cavities molds to make sure theHuangyan airline cups 4 cavities molds with high precision dimension.

Huangyan airline cups 4 cavities molds quality inspection

We have our own high quality cordinate bridge inspection machine to inspect the mould components before go into the next step.So we can make sure our Huangyan airline cups 4 cavities molds dimension in a good condition.

Come to us to buy Huangyan airline cups 4 cavities molds , you will be 100% satisfied.

Edited by Wendy Lu

Sales Engineer

Email:export@sinomould.com

Skype: sino.holdings.group-007

Phone:+86-576-81106962

This article is mainly talking aboutHuangyan fast food appliance stacking moulds ,Huangyan fast food appliance stacking moulds , Huangyan fast food appliance stacking moulds supplier Huangyan fast food appliance stacking moulds manafacturer, sell Huangyan fast food appliance stacking moulds

buy Huangyan fast food appliance stacking moulds

Huangyan fast food appliance stacking moulds design

We have our design team and R&D design department, so we have top design mentality to design Huangyan fast food appliance stacking moulds . We will make Huangyan fast food appliance stacking moulds moldflow analysis to make sure the optimize injection system and cooling system.

Huangyan Huangyan fast food appliance stacking moulds material

Huangyan airline cups 4 cavities molds , usually we use S136 or Din1.2316,or better Din1.2083,So to make sure the mold can be with long service life.

Huangyan fast food appliance stacking moulds making

We make Huangyan fast food appliance stacking moulds through 3 stage.First,CNC rough tooling, we will leave some tolearance for precision milling in this stage.After rough tooling, we will make heat treatment to get the Huangyan fast food appliance stacking moulds with higher hardness to

longer the mould service life. After heat treatment, the mould dimension will change a little

And also the shape, so we will use Italy imported FIDIA high speed milling machine to tooling

the Huangyan fast food appliance stacking moulds to make sure the Huangyan fast food appliance stacking moulds with high precision dimension.

Huangyan fast food appliance stacking moulds quality inspection

We have our own high quality cordinate bridge inspection machine to inspect the mould components before go into the next step.So we can make sure our Huangyan fast food appliance stacking moulds dimension in a good condition.

Come to us to buy Huangyanfast food appliance stacking moulds , you will be 100% satisfied.

Edited by Wendy Lu

Sales Engineer

Email:export@sinomould.com

Skype: sino.holdings.group-007

Phone:+86-576-81106962

Bakelite product is made by two ways. One is compression molding and another one is bakelite injection molding. The cost of Bakelite compression molding is lower than injection molding, but compression molding cost more in labor and has lower precision and rate of finished products. Compared with Bakelite compression molding,bakelite injection molding need more cost in moulds and machine. But it cost less in labor, high product precision, and high rate of finished product. So gradually, Bakelite injection molding becomes more popular than compression molding.

Injection molding parameters for some common type Bekalite:

Mould temperature | Barrel temperature | Injection Pressure | Holding Pressure | Screw rate | Cooling Time | |

Phenolic aldehyde | 160-180℃ | 80-95℃ | 100-170Mpa | 80-100 Mpa | 40-80 r/min | 15-50S |

Epoxy | 150-170℃ | 80-90℃ | 70-100 Mpa | 40-70 Mpa | 30-80 r/min | 60-80S |

| Polyimide | 170-300℃ | 100-130℃ | 70-100 Mpa | 40-70 Mpa | 60-80r/min | 20-70s |

Melamine resin | 150-190℃ | 80-105℃ | 60-80 Mpa | 40-70 Mpa | 40-50 r/min | 15-40S |

Bakelite is widely used for its extraordinarily high resistance - not only to electricity, but to heat and chemical action in electrical insulators, radio and telephone housing, kitchenware, jewelry, etc..

We Sino Mould ahs rich experience in making high quality Bakelite plastic mold. Any doubts about Bakelite injection molding, please contact me.

Miss Cina

E-mail: export@sinomould.com

Skype: sinomould-13

MSN:export@sinomould.com

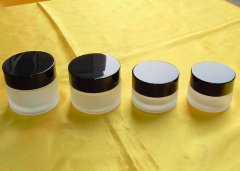

Mold is one of the important process equipment in modern industrial production area. Plastic water bottle closure mold is one of plastic mold.

Nowadays, customer find a supplier should be have rich experience, high quality product, and professional. Sino Mould is a company mainly producing plastic injection mould. We established in 2000, until now we have more than 20 years experience; we offer customer high quality injection mold with good price; we have 5 mould and product design department. We have mould testing workshop, specialized in final mould testing. Before mold shipping, we have professional quality check department to check the mold insert structure.