Sino Mould Co.,Ltd has rich experience of making the plastic mould, especially the containers mould, sweet/candy container, box container...also offer the IML system.

Not only making the container moulds, but also can offer you a production line. Sino is a branch of Sino Holdings Group, also specialized in injection molding machines and matched auxiliary machines, which named Turnkey project.

We are looking forward to our first business relationship in the future.

You can also visit our website: http://www.sinomould.com

E-mail: export@sinomould.com

China is a big country which can offer many goods all over the world.

And now I want to introduce china plastic mold.

China plastic mold is a very large industry, mainly gathered in Huangyan and Shenzhen area. The famous mold town--- Huangyan, Taizhou, gather more than 2000 mold company. The one of the best mold maker is ---Sino Mould Company, which company export about 2000sets of molds each year.

As china plastic mold leader, Sino Mould has advanced processing equipment, senior engineers and after sales service and so on. We have more than 20 years mold experience; mold area included home appliance mold, package mold, pipe fitting mold, automotive mold and so on. Welcome custom plastic mold, we will accord each project make a tailor-made solution.

If you have a plastic mold project under going, welcome you send us enquiry, we will give the reasonable price. China plastic mold will never make you satisfied.

Post by: Miss Diana

Email: export@sinomould.com

Cosmetics is growing popularized by many adults, so the demand is also increasing .We are the plastic cosmetics moulds supplier in chine, offer many different types plastic cosmetics molds and other platic moulds, also we are able to offer plastic cosmetics molding service for customers.

The plastic cosmetics mould can be the small parts mould or the cover mould and so on. For making the plastic cosmetics moulds ,we have the top tooling machine to process the mould steel, such as rough CNC milling machine to firstly form the shape and then do the finishing CNC milling process to reduce the error and make the size more precision.

We adopt the valve gate hot runner system to beautify the plastic cosmetics surface and reduce the labor cost .We have fully experience in making the plastic cosmetics moulds, so we can do it without any mistakes.

If you are interested in making the plastic cosmetics mould, and do hope to find the reliable plastic cosmetic mould maker. Come to us

Nowadays, more and more customer enquiry the plastic injection molding service from us, as we are famous plastic injection mould maker and offer injection molds machine ,we got good reputation among the worldwide, so we also do the plastic injection molding service.

The plastic injection molding service is special for the customer without the injection line in their factory, and maybe some countries with high labor cost, so they are prefer to make the product in China.

Sino have the professional and skillful machine engineer to adjust the machine parameter, which let the mould with best performance and can offer the best plastic injection molding, including check, simple assembly, pack ,stake ,etc. This will reduce you so many trouble.

Come to us ,if you are interesting to find the Chinese plastic injection moldingcompany

Plastic pipe fitting is closely connect with our daily life, it involve in the entire transportation task, from the clean water to the waste water. SINO offers the plastic pipe fitting moulds in china, many customers order plastic pipe fitting moulds from us.

We have more than 10 years experience in making the plastic pipe fitting moulds, therefore, there have all the types of plastic pipe fitting can offer you choose and we are worth to be trusted by you.

We ever helped the India customer built the pipe fitting molding company, supplied the plastic pipe fitting moulds, the PVC injection machine ,the staff training, the solution to the whole project.

If you want to make plastic pipe fitting moulds or want to do the project relate to the plastic pipe fitting, pls contact me, we can offer you all the solution about the pipe fitting moulds.

editor: Diana Email: export@sinomould.com

For the plastic drawer,plasticstronge are apply to house ware or industry widely, soPlastic drawer injection molding is a good making in the world, for a plastic drawer products molding by the plastic mould, injection machine, plastic raw martial.

We can support customer make a plastic drawer from parts design, the parts including drawer cover, drawer frame, drawer leg or drawer plug, we know which style is polular now, and will give you suggestions.

The drawer mould main is the dimensions of the assembling, so we will make high dimension control when the machining drawing moulds.

Our drawer moulds have widely for export, mainly exported to Italy, Argentina,Brazil, South Africa…

Please contact us if you have any plan to produce plastic drawer.

Contact me:

Skype: sino-mould-08

Email: export@sinomould.com

SINO has made various kinds of thermal box mould, thermal container mould, heat preservation box molds, etc. We can make high quality thermal box mold, no matter plastic inner pot thermal box or stainless steel lunch box.

The most important for the thermal box mold is fitting with each other. Especially some thermal box is made by plastic part and stainless steel. Good fitting have better heat preservation capacity. SINO MOULD is a heat preservation box mold manufacturer who can offer molding service for both plastic part mold and stainless steel part mold. You can custom thermal box mould from us. It will save you time to make the complete thermal box mold in one good mold maker, and don’t need to worry about the fitting. SINO will be your best choice for the thermal box mould.

Post by Miss Summer

Sino Holdings Group

MSN: export@sinomould.com Skype:sino-mould02

Web: www.cnmould.com www.sinomould.com www.dakumar.com

Email: export@sinomould.com

Sino Mould Co.,Ltd. famous chinese baby use moulds maker, baby use moulds supply China, specilizes in designing and manufacturing various types of baby use moulds.

We professional offer safety baby use moulds since 2000 with high quality and pretty competitive price. Sino Mould is major in high quality baby use injection moulds, including baby toilet moulds, baby bathtub moulds, baby toy moulds, baby chair moulds, etc. All the moulds are automic demoulding to decrease your time.

Until now we have set fine business relationship with customers from America, Europe, Asia and Africa. From the first beginning, sino offers you one-stop service. CNC milling machines, Sodick EDM, Agie Charmilles wire cutting are used to precision steel material tooling. UG, Catia, PROE are used to ensure precision mould design. Strict quality control ensure your moulds good before shipment.

Lucia

Mail: export@sinomould.com

Skype: sinogroup-11

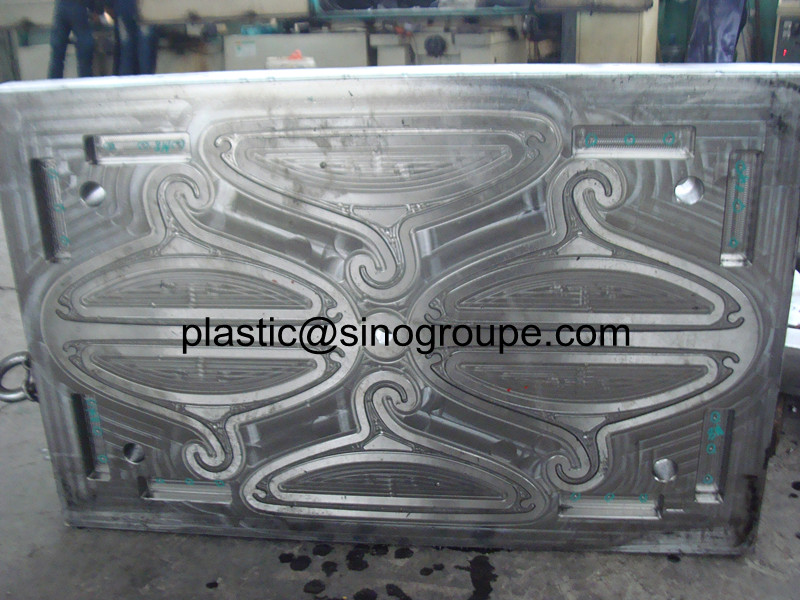

Looking for plastic hanger mold? SINO MOULD with years experience, offers youTurnkey solution of hanger molding.

Stack mould of plastic hanger:

Runner system: 12 point hot runner

Mould material: 718H

Cavity NO.: 6+6 stack mould

Cycle time: 20s

Suitable injection machine: DKM 780T

Ms Tina

Mail: export@sinomould.com

Skype: anole-01

SINO MOULD is specialized in manufacturing plastic toy brick mould in China. SINO MOULD has plastic rich toy brick mould design ablity and strong brick mould manufacturing facility which could offer customer high mould quality at best competitive price!

SINO MOULD as one of the most professional plastic toy brick mould manufacturing expert, has enegaed in making plastic toy brick mould for more than ten years.

We have three design departments, all the designers are all of rich design experiences who could design the most reasonable anddurable mould structure for customer.If customer plan to start a new project and we could help him to design the moukd according customer's requirements. Meanwhile, we will also offer many innovative ideas to help customer to gain more benefit.

Coming to the another important parts during the plastic toy brick mould process-plastic toy brick mould tooling, we have many high precision tooling machines in our factory. Such as high speed 3 axis,5 axis Fedia CNC machine, Sodick EDM, Sodick wire cutting machine, Mazark boring machine etc.

We are confident that SINO MOULD could be your best partner in the near future. If you have such requirement, welcome to contact us freely.

SINO MOULD is always at your service to offer you our best service!

Contact: Jessie

E-mail: export@sinomould.com

Online service:

making plastic toy brick mould,plastic toy brick mould manufacturer,professional plastic toy brick molding,famous plastic toy brick supplier,buy plastic toy brick in China

Majority plastic factory owners will forcus on how to improve and control plastic profucts quality.

Below are some key points for high quality plastic product:

Qualified plastic injection mould

1.Resonable injection mould design

Before we start designing the mould, we will discuss with customer about the material, production, available equipments and production environment.

After getting all these informations, we will arrange mould flowing analysis to make sure product could be fully well filled.

Once all the analysis been done, designer will carry out a primary mould design. Next step is mould design technical meeting, our experienced technical people will seat down together to analysis the mould design to make sure the all the points has been well designed.

Especially will pay more attention to the mould cooling system.

2.Mould machining technology

The other points is mould maching technology, perfect mould machining technology could gurantee the mould to be a good condition.

So that when we start production, parts structure and surface could meet our requirement.

3.perfect surface finishing

Perfect surface finishing could increase image visual effect , also make the part look like a high level products.

4. Suitable plastic raw material

Sometimes, different plastic material will also have different visual effect on the selling goods. We should try different material to see its effect.

Tina

export@sinomould.com