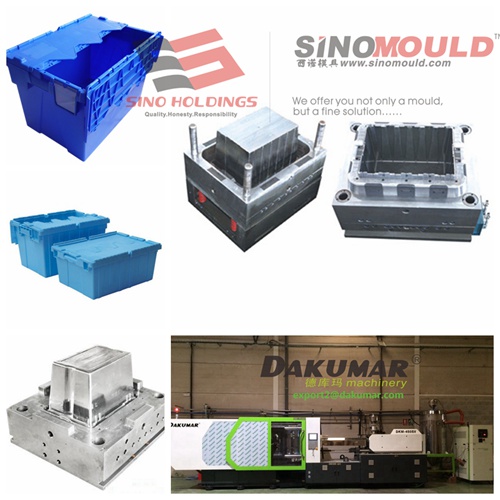

Sino Holdings Group is professional China Plastic Attached lid container injection mould manufacturer, we are specializein different crate moulds, container moulds,box moulds,pallet moulds.

We have good experience for attached lid container mould design solution, machining, assembly and mould test. The attached lid container, firstly mould such as European standard size with lid design.The cycle time of attached id container mould also is competitiveness in Sino Mould, special take care of the cooling system design, to let the productreach full cooling effect; slider of container mould can be by interchangeable,you can use one mould and change different wall style or height.

Base on our good experience on injection molding, our sister company Dakumar Injection machinery is manufacturing high standard injection molding, for Plastic Attached lid container project need considering two or three moulds, lid mould,container mould and handle mould, injection machine standard size 600*400*310mm need injection molding macine around 650Ton,Lid mould need around 400Ton.

So, Sino Holding Group offer not onlyplastic mould, and also injection machine, To give you fine solution for PlasticAttached Lid Container from Injection moulds , Attached Lid Container injectionmolding machine or other assistant equipment. Welcome you visit us if you arelooking Plastic Attached Lid Container Injection Mould or Attached Lid Container Injection Machine manufacture.

Email: export@sinomould.com

What’s up: 0086 15858625783

SINO MOULD is the most famous PET Preform mold makerin china and whole world. With more than 15 year of experience in manufacturing PET mould we have succeed in manufacturing 160 cavity pet preform mould .SINO has highly experienced design and technical team for PET preform mold manufacture.

With the continuous development in manufacturing advanced , fast, quality mould we are able to erect big business empire in the mould market throughout the world.

Proper selection of steel, precise processing, tolerance, German heating system are the features making mould more powerful to compete in the world market. We not only manufacture mould but provide fine and cost effective solution to the customers. We can also build the perfect mould for your project as per customers requirement like preform design, neck size, extra cores and cavities. We are truly specialized quality and cost effective PET mould manufacturer.

Some dominant features

1. Cavities up to 160

2. Interchangeable core and cavities , makes customers easy to produce different weight and design preform

3. Extra core and cavities to keep as spare parts

4. Advanced hot runner with German heating element

5. Stavax S420 steel for cores and cavity tempered with 55+/-2

Not only this our service includes life time servicing , production training to workers and prompt after sales service in effective way.

SINO HOLDINGS is your best partner for your achievement of great success.

Rahul Shah

export@sinomould.com

whatsapp: 008613989381153

Sino has some ready package mould on sale, such as water cap mould, flip top cap mould, PET preform mould, handle mould,etc.

As China famous package mould supplier, SINO PK could offer you high-precision& high-quality packaging mould. And for mould, we could offer you within one week. If you need these molds, welcome to contact me, also welcome to visitus to check mold running.

For ready package mold, pls see detail informations as following:

Item#1

Name:24 cav. Water cap mould

Raw Material: HDPE

Weight:1.4g

Gate:hot runner point gate

Product Size: PCO28

Mould Size: 500*430*460mm

Suitable Machine: DKM180

Item#2

Name:32 cav. Water cap mould

Raw Material: HDPE

Weight:2.2g

Gate:hot runner point gate

ProductSize: PCO28

Mould Size: 670*430*500mm

Suitable Machine: DKM250

Item#3

Name:8 cav. Flip top lid(auto-closure system)

Raw Material: PP

Weight:8.4g

Gate:hot runner point gate

Product Size: 48dia.

Mould Size: 600*400*520mm

Suitable Machine: DKM250

Item#4

Name:8 cav. Preform mold

Raw Material: PET

Weight:13g

Gate:hot runner Valve gate

Product Size: PCO28

Mould Size: 550*350*490mm

Suitable Machine: DKM180

Item#5

Name:16 cav. Handle mold

Raw Material: HDPE

Weight:2.5g

Gate:cold runner point gate

Product Size: PCO28

Mould Size: 590*530*405mm

Suitable Machine: DKM250

Any interests for ready package molds, welcome send your inquiry to me!

Skype:sino.pm

Whataspp:0086 138 5763 5311

Email:export@sinomould.com

Sino Mould has professional home appliance mold project teams, for instance, fridges, TV sets, air conditioners, washing machines, hand dryers, rice cookers. Our customers include the world’s leading companies from European, Middle East, East Asia, like Fagor fridge in Spain,Siemens home appliance worldwide, Gree Electric in China…

We develop our high quality molds with an eye on realization our customers’ requirements. For refrigerator products, surface quality play key action for customer marketing . For instance, refrigerator drawer parts, which are applied transparent plastic resin of GPPS, HIPS, ABS,PMMA,PC. We support Moldflow analysis to ensure suitable position of injection gate and avoid end plastic parts are out of shape. Meanwhile, with best workable cooling system and good steel application, like imported steelDIN1.2738,S136, your final plastic refrigerator drawers have very good appearance.However, during mass production, you also purchase suitable home appliance special plastic to ensure high polish of freezer outside parts.

At same time, we pay attention of part-to-part consistency and reproducibility. We are a single-source provider, capable of developing and manufacturing the full range of molds and matching hot runner systems needed to produce complete multipart components.

SINO develops and manufactures plastic products solutions for world injection molding applications. If you have home appliance projects, kindly contact Sino Helen team for supporting.

Posted by Miss Helen

Whatsapp 0086 15858625783

Email: export@sinomould.com

Skype: sino.group10

How to inspect the mold before shipment?That is an important problem clients worry about before shipping. They haverequirement before putting the order to supplier, while before shipping theywant supplier to be sure there is nothing wrong with die and products, andevery spare parts should be well before shipping.

Some of them will check the final samplesand required supplier to take pictures during shipping. A lot of client mayattend the final mold testing personally to check the mold quality beforeshipment, mold inspection prior to payment is very significant. But how to domold inspection?

Client has to know following:

1.Mold has good movement, themold running should be well, no rusty and polished well surface.

2.Ejection very smoothly, plasticparts can full automatically drop

3.Stable running. In Sino Mouldwe have at least 2 hours mass production before mold shipment.

4.Fast and reasonable cycle time

5.Parts must be fully filled,with no flash, silver streak, sink mark, weld line.so we could do quality control

6.Part dimension consistence withthe drawing tolerance.

If you attend mold testing with aboveknowledge, I think you can do very good mold inspection

yourself in plastic injection molding area,become more professional

Snow

export@sinomould.com

As a professional plastic injection moldingsupplier, different raw plastic material can be seen every day, such as PP, PC,PS,ABS,PAand so on. Today let us discuss about the ABS we daily used.

ABS is a thermoplasticity mixed materialusually used for plastic parts production. The inhererent color is ecru. We usuallyuse in auto parts, electrical parts, mechanical industrial and so on. We mayknow much about the parameter of ABS, While do you know inflaming retarding ABSmaterial as much as ABS material. The answer maybe ‘No’.

Inflaming retarding ABS is a ABS added acertain proportion of fire retardant, become a new ABS with inflaming retardingfunction.

Compared with normal ABS, when we offer alittle fire close to the inflaming retarding ABS, It will have normal performance,while normal ABS will inflame and even fire because its plastic instinct.

This material is usually used in someneeded area, such as electrical parts, toilet parts, inner parts and lightingequipment for auto parts.

And also inflaming retarding ABS isexpensive than normal one.

If you have anyplasticiinjectionmoldingquestion need to discusswith us , please feel free to contact me: export@sinomould.com.And if it is convenient for you, welcome to discuss face to face.

Snow

export@sinomould.com

Dakumar High SpeedInjection Molding Machine take the accumulator to help injection to gethigh cost performance to improve the speed, quicken the machine circle time,which are especially suitable for the ultrathin, precious and complicatedproducts such as following:

1.General packing products such as vacuum bottle,fast-food box, pudding box, etc. suitable for PP、PE、PSmaterial.

2.The high-requested packing products such as theshell of CD and DVD, telephone charger box etc. suitable for PP、PE、PSABS and PC material.

3.Engineers products, such as electronicconnector, plastic precision gears. POM、PA、PBT、PTmaterial.

About us:

Weare a professional manufacture of injection molding machine, clamping forcefrom 200 tons to 1300 tons.

Usingnew technology and good units, we make machine with CNC high-precision machine,assemble them under ISO quality process.

Wesupply good quality machines and turnkey project.

Wecan make energy saving series machines, high speed machines, PET bottlemachine, PVC fitting machines, also give high-quality mold, auxiliary equipmentand in-mold-labeling for bucket, cup and bowl and so on.

Ourmachine:

1.Servo motor injection molding machine

2.High speed injection molding machine

3.PET injection molding machine

4.PVC injection molding machine

5.Double color injection molding machine

Dakumar High SpeedInjection Molding Machine are sold all over the world. Welcome to visit us.

Email:export@sinomould.com

Skype:sinomould-01

WhatsApp:008613758679372

Polyvinyl Chloride (PVC) is the most commonly and widely used thermoplastic after PEand PP. Because of its inexpensivness ,durable and wide range of application PVC is used in construction and draining purpose. It also can be manufactured in both hard and softer durometers which enables it to be very versatile. With some advantages there are some disadvantages of PVC as it is toxic in nature and can hamper humans health.Due to its toxic and heat sensitive nature difficulities arise while molding PVC . Hardened Stainless Steel is required to mold down this plastic successfully.

SINO MOULD is one of the leading PVC Injection Mold manufacturer highly professional in design and manufacture of PVC molds. We design and manufacture high quality fitting molds but never stopped improvements and progress. We would like to take customers kind advice into consideration and 4 years ago we brought in new advanced mould design and strict mould processing from the world famos pipe fitting mould manufacturer IFW in Austria.

Our Pipe fittings mould series includes:

1: U-PVC pipefittings mould with normal and collapsible core

2: PPR pipe fittings mould with unscrewing and over molding

3: PP and HDPE pipefitting molds with metal inserts and collipsable core

Compared with other pipe fitting mould manufacturers , Sino Mould can produce the fitting mold with DIN 1.2316, advanced collipsible core and unscrewing design , optional Ni plating/Cr plating and mould outside painting and abundant spare parts.

SINO MOULD is extensively experienced in providing Turnkey solution in cost-effective and productive way including molds , injection machine, auxiliaries machine and all the necessary equipment necessary to built a perfect plant setup. Not only this our service includes life time servicing , production training to workers and prompt after sales service in effective way.

SINO HOLDINGS is your best partner for your achievement of great success.

export@sinomould.com

008613989381153

In Chinaplas 2017 exhibition, Sino Holdings Group showed one of latest achievements – 4 cavities 750ml one-off box mold.What are the strong points of this thinwall container mold? This rectanglecontainer has only 0.28mm wall thickness!

As we all know,main technical issue for thin wall container molds, less thickness makes its difficult to control uniform container wall thick. Especially for container wall is under 0.35mm, Sino R&D department devotes continuously to solve it. Through these years, we make container from 0.4mm, to 0.35mm, and now 0.28mm. However, it’s also required perfect processing technical and mold structure.

In this competitive global market, less thin wall thickness means getting large market. Like 750ml rectangle container, standard wall thickness is 0.45-0.5mm, and product weight is 17.8-18.2g. And Sino’s container thickness is 0.28mm with weight 10.8-11g. If you produce 1,000 pcs , your competitor will cost at least 17,800g PP resin, but you just use 11,000g for same quantity product. And you save 6,800gram cost to reduce your end product unit price.

We support this molds with hybrid hi-speed molding machine DKM200HH with MOOG injection servovalve. And it’s running 3.5seconds per shot! Warmly welcome your contact with us for thin wall container molding line .

Posted by Miss Helen

Whatsapp 008615858625783

Email: export@sinomould.com

Skype:sino.group10

Dakumarmachinery Co., Ltd, one member of SINO HOLDINGS GROUP, which is specialized inR&D, manufacturer, sale and service of plastic injection molding machinewith 5H. We have Dakumar-250 Servo motor inejction molding machine from 50T to 4000T.

Servo injectionmolding machine advantages:

1. It adopt ofhydraulic unit and used to high pressure and high speed injection molding

2. High speedresponse accumulator as a auxiliary power, using high sensitivityelectro-hydraulic servo valve, high precision displacement sensor to realizeinjection speed and injection pressure closed loop control.

3. Hydraulicsystem quickly response, high sensitivity, low noise

4. Adopt ofelectro-hydraulic type design, fully rational utilization of energy, low energyconsumption and high efficiency.

At present, servoinjection molding machine can divide to full hydraulic high speed machine, fullelectric high speed machine and electro-hydraulic high speed machine. Dakumaris now on developing the electro-hydraulic high speed machine.

Ourmachinery is widely used in different fields like food packaging, automotiveparts, home appliance, medical parts, household items for customers fromEuropean, American, Asia, Middle East, Africa, etc.

If you have demand in Dakumar250 Servomotor inejction molding machine, pls feel free to contact Miss Nancy.

WhatsApp:008613758679372

Skype:sinomould-01

Commodity mold , house hold mold, all the plastic items you see in your room or home are made ofplastic injection mold . You even can’t imagine how many plastic parts can be made by injection machine , Its out of Imagination. Products can be basins, tub , buckets, toothbrush, chair, table, stool, fork ,knife, hanger,drawer etc.,made by Injection molding.

SINOMOULD is the most famous and extensively experienced in the field of providing complete production line regarding household or commodity items production . With two magnificent branch company , SINO MOULD- having more than 20 year of experience in manufacturing Household mold and DAKUMAR Machinery - having more than 20 year of experience in the field of injection machine, has been able to erect big business empire in the world market.

We are truly specialized in providing quality and costeffective solution for whole Household items production line.Here are the list of Equipments with which anyone can setup their own factory.

1: Injection Machine

2: Injection mold

3: Auto Loader

4: Colour mixture

5:Air drier

6:Crusher

7:Chiller

8: Cooling tower with water pumps

We are dedicated to help our clients, to act as their technical adviser and to deliver individual solutions tailored to specific business need and challenging budgets. We are capable of meeting all small, medium and large scale requirement of organization, with professionals responsible for plant setup and necessary analysis.

SINO HOLDINGS GROUP is your best packaging partner for your glorious success.If you are in search of good injection molding company and want to setup new factory ,please contact us.

Sino Mould is a professional plastic container mould manufacturer, we supply high quality plastic storage container mould with injection molding solution. For the plastic container mould, we have experience for 10L container, 20L container, 40L container, 60L container, 80L container, 110L container mould and so on.

For the storage container mould, usually it consists of several moulds include container mould, cover mould, handle and wheel mould. We use P20, 718H steel material or other good steel material for the mould core and cavity. According to customer requirement, the injection gate could be cold runner direct cone and fully-hot runner system. With perfect cooling runner design, the mould could run stable and fast.

For the plastic container mould, if you need more information, please do not hesitate to send us enquiry. We could offer technical support with one stop service. Thanks.

Post by Ms.Celina

Whatsapp: 008615257606120

Email: export@sinomould.com