SINO MOULD, we have many experience for offering food container turnkey project which contains good quality food container mould, thin wall injection moulding, IML technology for food container. And this matured food container product line was popular among customers.

We chose the suitable mold steel for food container mould, the ejection way is stripper with air system. For some food container, we suggest to use beryllium copper which will greatly cut the cycletime and also well for container injection. According your food container volume, we will design a reasonable mold design. Normally, the container mold cavity was inserted which will better for food container demoulding. And in thefuture, this design will easy for mold maintenance.

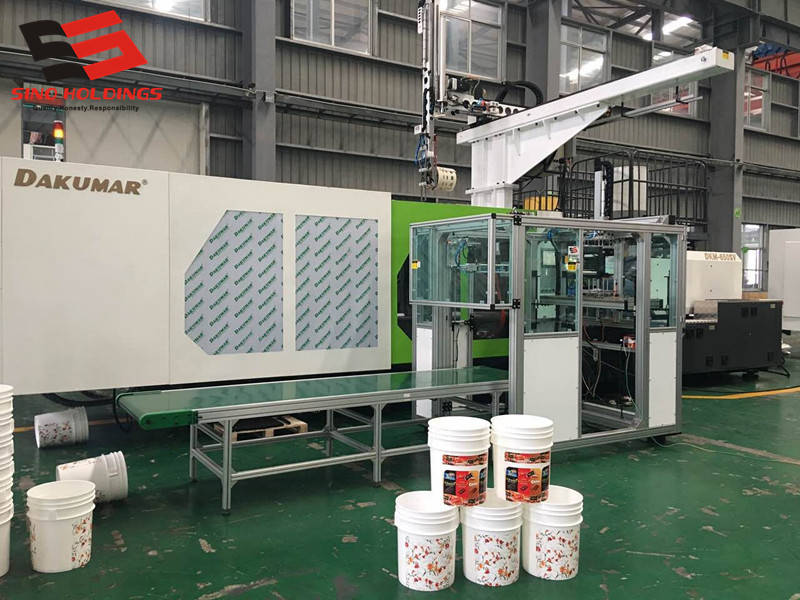

Our high speed injection molding machine has the idea of high speed, high energy saving, high injection precision, high stability circulation ability, high safety, which is well suitfor thin wall container injection molding.

IML technology:

According your need, we also will offer you IML technology. With the help of IML, it will make foodcontainer more attractive and more easier remember by consumer. The robot enterway from top or from side, this depends on your food container volume.

Areyou looking for IML molding technology? Are you looking for Plastic labeling production line chinese exporter?

SINOHOLDINGS GROUP will be your most suitable manufacturer for plastic turnkey molding provider, we pay more attention for the all equipment manufacturer detail and maintenance work. We know how to make a good machine or molds isbetter than a temporary profit.

Wehave more than 70 engineers now, no matter for molds or machine, our engineeris the top technical skill and can help you solve any technical skill questionor fast maintenance services. If you cooperated with SINO, we are sure you willbe satisfied with us.

Ourmachinery is widely used in different fields like food packaging, automotiveparts, home appliance, medical parts, household items for customers fromEuropean, American, Asia, Middle East, Africa, etc.

Allthe equipment for IML labeling as follows:

IMLinjection system.

Plasticinjection molding machine and auxiliary equipment, like auto loader, chiller,air dryer, mixer, air compressor, etc.

Plasticmolds;

Plasticraw material;

IMLlabeling system

Robotfor label collecting

Robotfor feed the label into the mold and pick out the plastic labeled parts;

Robotfor stacking the plastic labeled part;

Conveyor

SINOHOLDINGS GROUP is professional for turnkey solution services. Welcome tocontact us for more detail for the IMLProduction Line with Labeling.

Email:export@sinomould.com

Skype:sinomould-01

Mobilephone: +86 137 5867 9372

SINO MOULD has rich more than experience and enjoy excellent more than twenty years’s in plastic injection molding..Every year we make and export our plastic mold to our customers from all over the word including the

SINO team place importance in design andanalysis QC control: SINO designers and engineers spend more effort in the mold design analysis process. For some newly developed projects of customers, designers making moldflow analysis for studying the condition of mould running. So the quality control of mould desinges been more rigorous. We engage in the biggest possibilities to avoid anerrors or short-comings in the mould design. So that we can solve man mould problems in the computer before happen in the workshop.

We have strong Project Team and Sales Team.We have many professional department for each different projects.

Thin-wall high speed injection mould

Automotive mould

Pipe fitting mould

Chair&Table mould

Industrial Trash Bin Mould

Crate & Pallet Mould

Home Appliance Mould

Kichen Ware Mould

……………

If you are looking for plastic injectionmould & injection machine, welcome to contact me, we will be your best choose.

Posted by Ms.Amanda

Whatsapp/Tel:0086 13867653757

E-mail:export@sinomould.com

Skype:sinogroupe-61

Sino Mould is a famous plastic injectionmould maker in China ,we specialized in offering customer turkey solution for binmould,paint bucket mould,in mold label bucket and so on.So far ,we have offer morethan 300 lines of the whole turkeypailbucket project,IML bucket productionline.etc for our customers in different countries all around the world .

Why customer choose SINO to offer their pail turnkey projects ? because ,ourfactory can offer customers one –stop service ,including bucke injectionmachines ,bucket injection moulds ,plastic material ,equipment installation andprofessional technical consultants , and meanwhile ,our engineer will layoutthe design of the factory and buildings for you at the same time . and afteryou confirm the one-stop service of the turnkey projects , such as bucket , youcould send your staff to our factory for professional training .

As we own a professional team , when youhave any question or doubt ,we could help to solve your problem you are facingpromptly .one of the most helpful advantage is that we can handle the bucket turnkeyproject with fast delivery time . Before you purchasing , we will provide youfullfil technical support and the whole plant design ,including water ,air,power ,crane , the safety standard and so on .

If you have any projects need us to offer paint bucket turnkey solutions for the pail bucket production line you want to buy for your plant . welcome to send your enquiry toour mailbox .

Posted by Selinda

E-mail : export@sinomould.com

Skype: sinogroupe-selinda

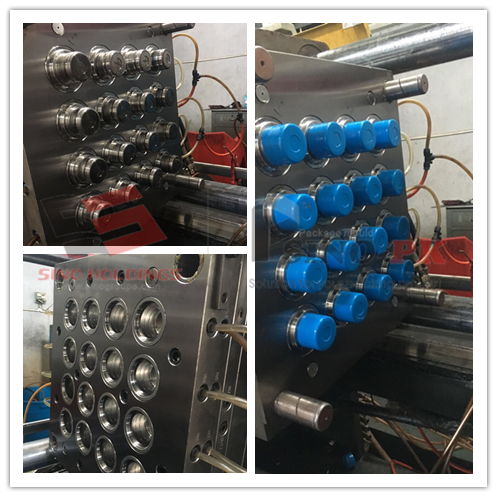

Recently preform mould become more and more popular in the world, many customers begin to establish the preform production line in different countries met their requirement. For the plastic preform mould supplier, why so many customer come to our company, it must has some reasons for that.

The advantages of our preform mould are as below:

1.We use S136 stainless steel with HRC 48-52, this steel is offered by Stavax Sweden.

2.About ejection type, we use valve gate for beautiful gate finish. There will be no tail, so you don’t need to cut the tail by hand.

3.We use Anole hot runner system with German heating elements. Anole is our subsidiary company; we will take care of both mould and hot runner after sales, so you don’t need to worry about the hot runner problems.

4.We are the most professional preform mould company in our area with rich experience on preform mould. Every year we make around 500 sets of preform and cap moulds, up to 96cavity.Making 72cavity preform mould, we can make cycle time up to 22s.

5.We use advanced lathe machine Mazak from Japan for preform mold tooling with high precision. We can reach the required weight by one time tooling and could ship mould after only trial.

6.You just provide the production sample and the machine parameter, and we can finish the production and mould design in half a day.

7.We can offer our customer turnkey bottle production line, including cap mold, bottle blowing mold, preform mold, bottle blowing machine, plastic injection molding machine and auxiliary etc.

8.In usual case, we can one-time ship when the mould was finished.

9.We have special project manager to tail after every order, and our mould is tailor-make for you.

10.We are professional in making preform mold for 14 years and sell all over the world.

11.We will offer spare parts, like core/cavity inserts, heater with the molds, so you could replace the damaged parts quickly.

12.We can offer you one year guarantee. If there is any problem, we will offer new parts free of charge during the warranty period.

13.Sales engineer offer a 24h service on line, it make inquiry & quotation & communication easy and convenient.

14.24 hour available for after sales service

With above service and advantage, what are you waiting for ? if you are just looking for a suitable preform mould supplier, pls come to me and for further inquiry.

Martina

Skype: sinomould-17

Email: export@sinomould.com

Phone: 0086+15215807221

Are you wanted to cooperate with a high reliable car light mold supplier? Pleasewelcome to SINO AUTO MOTIVE MOULD CO., LTD. We have richexperience in making different plastic carlight molds for many years with strict quality control, short delivery.

Car light mold need high tooling equipment to control the precision and also have high polishingdemanding. Because of car light mouldcomplex structure, we invested much money to buy high precision tooling equipments and now all of them normal operation and have maintenance service. The equipments contains Italy Fadia high precision Five-axis computer numerical control milling, Japan Shaddick mirror spark machine and so on. The application of this equipment will make car light surface looks more shining which will save more time on mold polishing.

In addition, we have a strong car lightmould design team. Most of mold designers have at least 5 years car light molddesign experience. According customer requirements, we will offer you reasonablecar light mold design with good cooling system, air venting system, and optimalejection system. And take advantage of UG, Catia,our car light mould design has more free choice and modify space.

More question regarding to car lightmolds, please feel free to contact me.

From: Stacy

Skype: sinogroupe-62

Email: export@sinomould.com

Sino Mould specializes in manufacturing and designing various pipe fitting moulds for decade years, and has been continually tailoring our design tomatch the irregular shape PVC, PP-R, PP and PE fitting moulds. From large bend drainage fittings to multiple direction branch fittings, we adopt the collapsible core, curve sliding system, and unscrewing device to meet the most complex pipe fitting applications.

We have more than 20 years rich experience in offering various types of PVC pipefitting moulds, and can also offer the whole solution for the turnkey project. Sothese years we have attracted a lot of customers who come from America, Russia,Mexico and India everywhere in the world.

Eachmould made by Sino Mould used top grade raw material that are sourced from trust worthy vendors of the market. Because PVC material’s high corrosive, normallywe suggest to use DIN1.2316 made by Thyssen Krup German, and guaranteed mouldlife at least 500000 shots under you maintain moulds according to our mould specification. Furthermore, the pipes have proper wall thickness enabling themto bear the high working pressure load and help customer cut cost.

Ifyou want to develop PVC pipe fitting market, but do not know PVC pipe fitting well, come to Sino, we will offer you PVC pipe fitting turnkey project. Except offer PVC plastic moulds, we also offer your PVC injection molding machine andarrange our engineer to go your factory to do commission and train your staffs.

Postby Miss Mandy

Email:export@sinomould.com

Whatsapp:008615757610702

World famous PET package moulds maker in China. SINO MOULD is one of the best package mould manufacturer. You can buy PET preform mould, cap mould, thin wall mould from SINO MOULD.

Multi cavity PET preform mould, we can make the mould from 1 cavity to 120 cavities. More cavity mould can reach more production output, but not the more cavity the better. Big PET preform mould will need larger PET injection machine, that’s cause producer more investment. Normally we suggest to make PET package mould with 32, 48, 64, 72 cavity. In this way, mould and machine can working stable and meet customer’s target demands. About mould detail information, please take 20g PET preform mould for reference.

Mould name: 20g PET Preform mould

Cavity number: 32 cavity

Steel: S136, HRC 48-52

Mould size: 792x1080x550mm

Hot runner system: 32 tips valve gate Anole hot runner

Cycle time: 18 seconds

Suitable injection machine: Dakumar 350PET

Delivery time: 50 days after down payment.

For mould quotation, you can contact me via email: export@sinomould.com or skype: sino-mould02. We can help you customized most suitable PET package moulds for your company. Also our brother company Dakumar Machinery supplies high quality injection moulding machine.

SINO is a professional paint bucket mold company.We are specialized in manufacturing different kinds of paint bucket molds roundpaint bucket mold, square paint bucket mold, the capacity from 1L, 3.6L…18L, 20L…Below is our 18 liter paint bucket and lid mold specification, for yourreference.

1. Material of mold core and cavity:Din1.2344(H13) with HRC42-44.

2. Copper Beryllium (moldmax) on the topcore and cavity edge, leads to best cooling effect for high speed injection.

3. Material of mold base: P20 made in China.We can self-make the mold base, use standard mold base, such as LKM, etc.

4. Anole hot runner included moldtemperature controller, hot runner system can save material and reduce cycletime.

5. Inductive proximity switch be installedinto the mold to control ejection process precisely

6. Hasco standard cooling Z801/19 quickcoupling& nipper.

7. Bucket mold with 360 core venting system.

8. Bucket mold with in molding labeling system.

Our paint bucket wall thickness is even,leaking test, stacking test and dropping test have no problem. Pls kindly sendme your drawing or 3D design, then we will quote exact price with detail moldspecification for you.

Postby Miss Mandy

Email:export@sinomould.com

Whatsapp:008615757610702

Sino Mould is one of Chinese famous muti-cavity 5 gallon cap mold designer, 5 gallon cap mold maker, 5 gallon mold exporter from 4 cavities to 64 cavities. Below are short introduction of our 5 galloncap mold features.

1.Mold cavity and core steel we adopt imported H13, DIN1.2316, S136 etc.

2.Adopt special cap mold treatment technology, core and cavity parts using

corrosion resisting mirror steel, surface hardness can reach HRC60°.

3.Hot runner system: we use our own brand Anole hot runner system to save material,reduce cycle time and save labor cost. You can also choose YUDO, HUSKY or other famous brand hot runner system as your demands.

4.Excellent water channel design: each cavity and core has independent cooling

system, which can shorten production cycle time.

5.The mold cavity can be changed, which is convenient to change remark of the cap.

6.Mold can be automatic demould, which can help customer reduce labor cost.

7.Mold life time can be guaranteed with 2 million mold times.

We will be your reliable 5 gallon cap mold supplier in China, so pls kindly share your

requirements, or 2D, 3D design with us, we will quote competitive price for you.

Post by Miss Mandy

Email: export@sinomould.com

Whatsapp: 008615757610702

SINO MOULD is specialized inmanufacturing different plastic mould, we have more than 20 years experiencesin making crate mould. We could provide you crate mould, crate products, crateturnkey line solutions. We are foldable crate mould maker, foldable crate mould supplier, foldable crate mouldfactory China, foldable crate mould manufacturer, foldable crate mould company.

SINO MOULD used makechocolate crate mould, beer crate mould, vegetables crate moulds, milk cratemould, egg crate mould, fish crate mould, bread crate mould, fruit crate mould,foldable mould, etc.

We will use 45#, 40Cr, P20,2738, 2316, 718, S136 steel to make crate mould. P20 and 718H will moresuitable for crate mould.

Cratemould design is decided by customer's requests, such as cycle time, employeequantity, injection molding machine, specification, shrinkage or certainplastic material, etc. we adopt highlight technology to manufacture the mould,which satisfied all clients requests, makes the foldable crate surface morelighting and more strength.

If you are interested in our fordable crate mould, pls feel free to contact me China cratemould maker.

I will send you more details of our foldable crate mould andproducts.

Welcome your down to visit our company.

Email: export@sinomould.com

Skype: sinomould-01

WhatsApp: 0086 137 5876 9372

SinoHolding Groupe is a leading die casting mould company in China, specialized in making aluminum die-castingmoulds and injection moulds,as well as injection molding machine. we are offeringour customers one stop purchase service, from design,die making, aluminum product surface treatment, part produce and assembly.,etc.For 23 years , Sino Mould has attracted thousands of customers allover the world . what is the source of the company success ? we are company offerdie casting solution for customer.

Strong Design Team :

Sino team place importance in design andanalysis .our professional engineers and designers spend much efforts in themould design analysis process. For some newly develop projects ,our designerswill make mold flow to analysis and study the condition of mould running . weengage in the biggest possibilities to avoid any errors .so that we can solvemany moulds problems in the computer before happened in the workshop .such comprehensive analysis let us our engineer to select the best techniquesolution and all those guarantee our customer the highest quality and functionideal of the products .

With our highly qualified staff, topquality, perfect die casting mould solution and prompt pre-sales and aftersales ,we are confident believe we are the best supplier for you !

E-mail:export@sinomould.com

Whatsapp:008615858629913