Sino Mould has strong management for tequality and tooling precision control,and has our own R&D department for project research and new item development,with advanced software for design and analysis for the project.We also have more than 30 engineers for mould analysis and mould design, and we own a top mentality working team for project management, quality inspection and processing control.

During our years,we have develope dinternational market for OEM and after-sales market for brand asSUZUKI,HONDA,NISSAN,TOYOTA,,and so on. We extend our warmest welcome to you paying a visit and SINO HOLDINGS.

SINO Automotive company is also successful indeveloping various plastic injection molds through superior platics technology for automotive interior trim parts, such as instrument panel,door trim, glovebox, console box cup holder,

Bumper Mould:

Steel Types:DIN1.2738

Injection system: Synventive sequence nozzles

Ejection system:

Hydraulic cylinder

Mold cycle time:45s

Mould delivery:110working days,

Surface finishing:moldech,texture

For auto lamp injection molding, apart from custom auto lamp plastic molding machine,molding technology is the key points.Sincecar lamp is transparent and be used in car industry, the quality requirement issuper-high, so during auto lamp parts molding,any bad finishing can not be accepted, thusthis requires high car lamp molding technique, plastic material must be driedadvance,molding t emperature setting,back pressure are important.

Post by:Ms.Amanda

whatsapp/tel:0086 13867653757

E-mail:export@sinomould.com

With plastic turnkey molding linesmore and more widely applicant among plastic molding field, sino holdings gainedgreat praises of high quality high performance turnkey production lines, suchas pvc pipe fitting turnkey moldinglines.

We have delivered many pvc moldinglines to our customer, such as Jordan, Egypt, Ecuador, Venezuela and so on.

For PVC pipe fitting Mould ( forhigh pressure and low pressure = for water supplying and water discharging) ,we have developed such as:

1. CPVC pipe fitting mould for high pressure.

2. UPVC pipe fitting mould for water drainage

3. PVC belling pipe fitting mould( with collapsible cores for pressure watersupply).

4. Electricity cable pipe fitting mould, built in-wall various PVC pipefittings.

…..

Due to pvc special materialfeatures, we adopt high standard stainless steel to avoid corrosive duringproductions. And it would be hard enough to HRC 40-44, suitable for low meltflow index material productions. And in case of pvc power materialmanufacturing, we have special design on mold gate and runner system, as wellas injection machine fitting areas. We aims to offer you high quality pvc pipefitting turnkey molding lines. For any questions, pls feel free to contact withus.

Ms Diana

Mail: export@sinomould.com

Wechat/whatsapp: 0086 13757677056

We are aimed at offering customer high quality stool molds based on customers’ requirements.We keep improving how to benefit ourclients and help them achieve excellent production capacity at fraction ofcosts. We can provide you with stool sample that we have produced for customers and quality case, to provide you with the most satisfactory stool mold technical solution.

The detail specification of stool mold madeby us

1. No. of cavity: Usually the No. of cavityis one due to stool size and mold design.

2. Cavity and core steel: We provide manykinds of stool mold steel for customer to choose, such as P20, 718, S136, H13,#45 and so on. Good steels are the basis of long life of molds and high qualityof products. All the steels we provide are made by famous steel manufacturersat china and abroad, the quality can be guaranteed.

3. Heat Treatment and HRC: We commissionprofessional company for heating processing. Different technologies areemployed in different components and steels to assure better polish and longusage. The Hardness of core and cavity of stool mold can reach HRC 32-36 afterpretreatment.

4. Tooling processing: All components areprocessing by CNC lathes and the assembly work of stool mold is finished by themakers with rich experience over 10 years.

5. Mold shots: Stool mold shots can reachat least 30 million with good steel, reasonable heat treatment and preciseprocessing.

6. Cycle time: 20-32S

We will offer the best solution for your stool project, and assist you develop new and attractive stool to make hugeprofit.

Post by Miss Mandy

Email: export@sinomould.com

Whatspp:008615757610702

SINO industry foldable crate mould meet European market demand, and with morecompetitive price standard for high speed cycle, recycle material application. Wehave the product sample with lid and without lid. The size are 1200*1000*1000mm46kg without lid, and 1200*1000*1000mm 50kg with lid.

It have followingadvantages:

1.Stacking for 3 layer;

2.Easy handing with forklift;

3.Long fast for stock and foldable afterrecycle use

We can offer customers following services:

Different customers, different cases, wecustomize for you.

customer service: we have advancedinternet platform, so the customers can communicate with our engineers

online and solve your problems online.

Before-sale service:

offer hotline consulation for products andtechniques. We can design moulds as your special requirements.

Mid-sale service:

offer installation, adjustment service, andpractical training.

After-sales service:

24 hours repairing service. offer you1year's guaranteed for whole mould, but our service is forever.

SINO place importance in design andanalysis control, for some newly developed projects of customers, our designermaking moldflow

analysis for studying the condition of mouldrunning. we engage in the biggest possibilities to avoid any errors orshort-comings in the mould

design. so that we can solve many mouldsproblems in the computer before happen in the workshop.

We offer you not only Industry Foldable Crate Mould,but a fine solution…

Cell phone/ Wechat:008613758679372

Skype:sinomould-01

Email:export@sinomould.com

Nowadays, plastic bottles are widely being used for both domestic and commercial purpose. It is very convenient to carry a plastic bottle around as it is light and can be disposed of easily. It is also economic to buy them because they are cheap and do not require investment like a metallic container would do. So, over the years, preform mould is more and more needful.

Our company is good at preform moulds for more than two decades, with high quality, accurate technology, advance machine technology and processional design department, which makes us famous all over the world. We design Chinese preform moulds with hot runner system-valve gate system, preform mould with hot runner system elements interchangeable on the machine, which will be more convenient and save investment for your customers. Nomatter how difficult the structure is, we promise that it will satisfy you by the preform moulds. We use PET, PP or PC for preform molds; it depends on theproducts function and devoted a long experience and time devoted for achieving our client’s requirements. Once you tell us your requirements of your moulds,the tailor made solution will be offered to you.

As a preform mould manufacturer and the multi-cavities hot runner moulds maker, the machining process and the dimensions controlling is the most important issue to get a good quality mould. If you want to get agood quality preform mold, welcome to contact us.

Shelly.Lu

Email:export@sinomould.com

Skype:dakumar_machinery

Web:http://www.sinomould.com

Shampoo flip top cap injection mold is different to other bottle caps, such as water cap, drink cap, oil cap, 5 gallon cap, etc. But all of them are produced by plastic injection molding technology.

Shampoo flip top cap key technology points:

1.Shrinkage rate:most of the cap material is PP, PE. Different material will have different shrinkage rate. It will affect cap and bottle fitting.

2.The size of flap is very important. It will affect the cap open and close effect.

3.Tolerance: tolerance will affect cap fitting and shampoo using.

4.Welding line: precision process will make the shampoo flip top cap very beautiful, less the welding line.

5.Water shutoff: some of the cap will have water shutoff or not have this requirement, which was decided by the internal liquid.

6.Voice: some customer will have requirement to the capping voice, this specification is very important to the product using.

SINO has rich experience in all kinds of package products shampoo flip top cap injection mold , We have high precision process machinery, most of them are located in constant temperature workshop. Because the steel also will expand with heat and contract with cold. Only when the temperature is stable, the process will be precision.

written by: Candy

email: export@sinomould.com

We are aimed at offering customer the turnkey project for their thin-wall container molding plant set up help customer establish plant according their investments. We have rich experience inoffering customer the turnkey production line. Actually, we have made more than 50 turnkey thin-wall containers production line for our customers from all overthe world.

General thin-wall container has three types: round, oval, square, and the wall thickness of thin-wall container is less than 1 mm, but our company has successfully done 0.4mmwall thickness container molds to help customer cut material cost. If you want tomake 1L container mold, the best wall thickness is 0.5-0.6mm, but if the volume is 2L,0.6-0.7mm must be best choice. The material of thin-wall container usually chooses PP,and the shrinkage rate is 1.5% 2.0%. About MFI melt index, the thinner wallthickness, the bigger melt index. The greater the melt index, the better liquidity,but the worse toughness.

Inorder to realize high productivity, we offer high speed injection moldingmachine with robot system. For example, for 4 cavity 500ml thin-wall container mold with 0.38mm wall thickness, the cycle time is less than 3.8 seconds. And we can select all the necessary auxiliaries for the whole production line, like auto loader, air dryer, chiller, crusher, conveyor and so on.

If you are seeking for thin-wall container molding solution,pls feel free to contact me, Iam glad to reply you.

Post by Miss Mandy

Email: export@sinomould.com

Whatsapp: 008615757610702

As a world famous crate innovator and a professional crate manufacturer, Sino Holdings Group has made more than 2000sets crate moulds in different sizes and designs, include vegetable cratemould, bottle crate mould, thin wall crate mould, etc.

Our high speed crate mould has many quality points,such like long life with high quanlity steel material, high speed performance with ideal cooling, air venting solution in the crate's molding keypoint area, special hot runner system design with filter for recycle material.

Thin wall crate usually use PP or HDPE, the min.cycle time can reach 15s while with BeCu. We will test the crate mould before shipment, and we will pay attention on the crate weight, production strength,overlay, burr and flash, welding line, cycle time.

Sino Mould has rich experience in making thinwall crate mould, and has perfect equipment in our factory. If you wantto make thin wall crate mould or just want to buy crate, please come to Sino, here you can find what you like. In a word, Sino can meet your any requirement in crate mould or related project.

Shelly.Lu

Email:export@sinomould.com

Skype:dakumar_machinery

Web:http://www.sinomould.com

As china famous injection molds maker, Sino has more than 25years experience in injection molds making. Especially, in the field of PET water bottle molds manufacturing.

For water bottle item supplying, you need the following molds:

1. PET preform mold

For water bottle,usually is 150ml, 250ml, 300ml, 330ml, 500ml, and 750ml. Bottle capacity different, PET preform gram weight also is different. For example, 8g usuallyfor 150ml, 16-18g for 500ml. For PET preform mold, usually mold steel is S136,mold base is P20. We will adopt independent self-locking mold structure to avoid products eccentricity and keep mold life longer.

2. Bottle blowing mold

Usually for blowing mold, we use P20 or Al, it depends on customers' requirement, and for bottle mold, according to your capacity requirement, we can make mold with 2cavity,4cavity, even more as appropriate.

3. Caps mold

For cap mould, raw material usually is PP, as preform mold, mold steel is S136. For cap, common neck is 28mm PCO, 28mm BPF, 28mm ROPP, etc. As we know, there is anti-theft ring at cap. To make this ring, there are two ways. One is by slider, molding in mold. Another way is making by cutting machine after molding. For caps projects, you need to consider it.

Sino supply high quality PET water bottle molds, any interests, welcome send your inquiry to us! We will be happy to offer you best solution.

Miss.Ysaline

Wechat/tel:+86 138 5763 5311

Email:export@sinomould.com

Are you looking for Thin Wall Container Production Line supplier in china?

If yes, we areconfidence to tell you that SINO HOLDINGS GROUP could offer customers complete thin wall system. Weare the manufacturer for thin wall container production line in the market.

We can offer customershigh speed for our customers in the world market. We will help them make this project feasibility analysis, forthe thickness whether suit for the IML system and suggest so good structure upgrading, provide customer humanistic suggestion.

We take one of the thinwall container as an example:

1.Mouldinformation:

Cavity: 1 cavity

Cycle time: 5s

Product weight: 47.8g

Plastic materials: PP

Runner: 1 tip hotrunner

Steel: S136

2.Injectionmolding machine information:

DAKUMAR 300T high speedmachine

3.Auxiliaryequipment:

Auto loader

Chiller

Air compressor

Mixer

Crusher

4.IMLlabeling system

Robot for labelcollecting

Robot for feed thelabel into the mold and pick out the plastic labeled parts;

Robot for stacking theplastic labeled part;

Conveyor

Now more and morecustomers like Dakumar machine, not only for its good quality, but withsuperior service. Welcome to contact us for more detail for the Thin Wall Container Production Line.

Email: export@sinomould.com

Skype: sinomould-01

Mobile phone: +86 1375867 9372

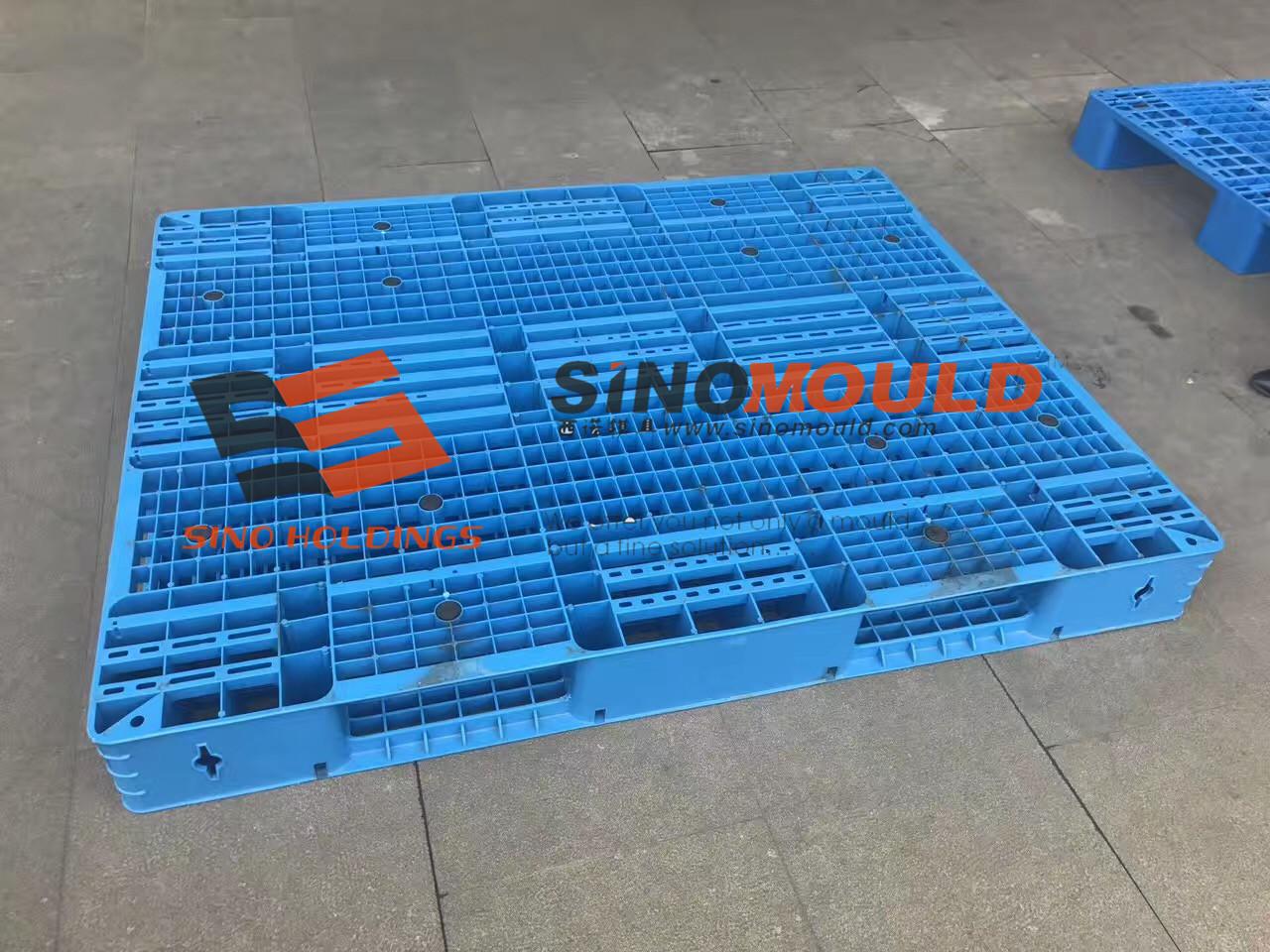

Dakumar machinery Co., is one of the members of SINO HOLDINGS GROUP, we specialized in offering turnkey solution for plastic production line, such as plastic crate production line, plastic chair mould production line, Pipe fitting mould production line. We have established over 600 of projects all over the world.

We have established over 850 projects all over the world for over 120 countries. We offer moulds,

machine and accessory for all the equipment, which will be very convenient to you. especially for pallet production line.

SINO has rich experiences for offering customers pallet production line services. We have 2 subsidiary company---SINO MOULD&Dakumar machinery, who could supply high quality mould the recommend you the most

suitable injection molding machines. On the same time, we could offer youauxiliary machines, such as

auto loader, chiller, dryer, mixer, etc.

For pallet mold,itis very important of injection gate position and injection gate tips. We will make mold

flow analysis, and choose suitable injection gate to keep good weld line.About mold steel, usually P20

for core &cavity, 718H for slider.

If you are interested in industrial pallet molding line, or want to start new plastic injection molding factory,welcome to contact me, we will be happy to offer you best solution.

Contact person: MissNancy

Email: export@sinomould.com

Cell phone/ Wechatnumber: +0086 137 5867 9372

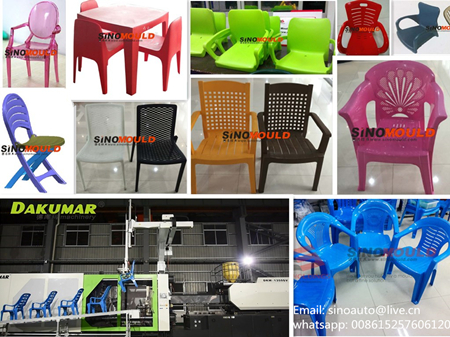

Sino Mould is a professional manufacturer for plastic arm chair moulds, we supply different types of chair moulds with one stop molding line solution.

For the plastic arm chair mould, we use P20 steel material made in China for the core and cavity. The cooling runner is well-designed to fast cooling and let the chair mould running fast and smoothly. It is very important to get comfortable parting line for the chairs, in order to show high quality products, Sino Mould use high precision milling machine for the parting line tooling, it could save fitting time and the parting line much better than common CNC tooling. With smooth parting line, the Chair is qualified after molding, it could make sure for safety seating.

Sino Mould pay much attention during plastic chair design period, we could check the strength, stacking with 20pcs chairs on the drawing to keep it in the same vertical line. With our rich experience for the chair mould production, we could offer you high quality plastic chair mould.

If you have new project for plastic chair molding line, welcome to contact us for more information.Thanks.

Post by Miss Celina

Email: export@sinomould.com

Whatsapp: 008615257606120