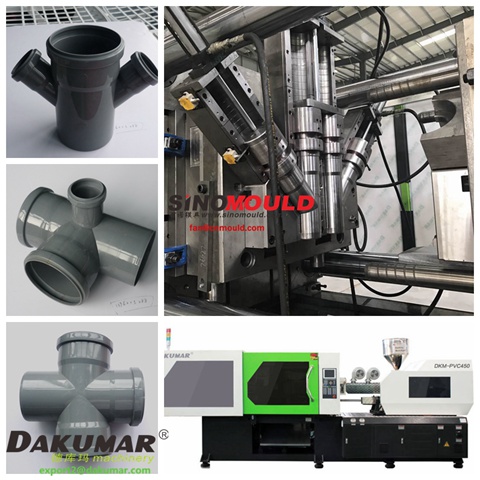

China Professional Injection molding mouldcompany –Sino Mould is a High quality UPVC cross Pipe fittings injection mould Manufacturer.

Sino Mould is located Zhejiang Praveen China,we have rich experiences on UPVC,PVC,PPR,PE pipe fitting injection mould making,UPVC mould in different structure, like cross type type, Y type etc…considering steel by tempered steel by hardness around HRC42-46, for long time wear andmould life. For cross type pipe fittings mould making we usually by reasonable design for parting line design or collapsible design, Slider remove system drive by Hydraulic cylinders with famous brand Anole, let the movement in stable and smoothly; strict wall thickness control and assembling tolerance control; precision surface finish with smooth ejector pin mark and gate mark; fulfil multi-direction collapsible core system fitting shape. All the features is for a long time UPVC cross pipe fitting injection mould.

If you customer have production line or PVCinjection request, Sino Holdings another member-Dakumar Machine can give good suggestion sand offer about PVC injection machine, Sino Holdings already finished many PVC pipe fitting injection molding line or mould in different countries of world,like Germany Ecuador, USA, Egypt, Saudi Arab and so on…

We know the key point of pipe fitting moulds,injection process and parameter adjusting, if you are looking for a high quality UPVC cross pipe fitting mould or injection machine. Welcome you contactus:

Miss.Vivian

Email: export@sinomould.com

What’s up: 0086 15858625783

SINO is specialized at offering moulds plastic cap moulds; bottle handles moulds for packaging solution. We are experienced with different kind of handle moulds, with/without hot runner, with/without slides…and for different size such PCO28 neck. 38mm neck, 48mm neck… We have supplied plastic handle moulds to countries like Spain, USA, Italy, South Africa,Austrilia…And now we have one ready handle moulds for sales.

Below is the deatils for ready bottle handle molds:

Handle model: suitable for PCO28mmbottle

Cavity number: 16 cavities

Runner system: three plate mould (cold runner)

Mould size: 2.5g

Mould size 590*530*405mm

Machine size: around 200-250T injection machine

Material: HDPE

Ready handle Mould Feature:

Each cavity is inserted with Core&cavity interchangeable, easy maintenance in future

Cold runner three plate moulds, no troubles with hot runner

With output around 4000pcs/hour

S136 Stavax stainless Steel from Sweden with hardness around HRC45-48

Strong mould design suitable for high speed running

Samples and video sare available upon request

Both product an dmould design drawing available upon request in both 2D&3D with both hardcopy and soft copy

Turnkey solutionfor handle moulds, machine and turnkey solution

Fast delivery timewithin 7days upon payment

If you are interestedwith the ready handle moulds, welcome to contact SINO MOULD for more details.

Contactinformation:

Overseas sales department

whatsapp 0086158685625

SINO bottle Crate mouldsmeet European market demand, and with more competitive price standard for high speed cycle, recycle material application.

We produce also industrial use logical crate and pallets moulds, crate size up to 1100mmx1000mmx800mm,and pallet size up to 1200mmx1200mm.

SINO place importance in design and analysis control, for some newly developed projects of customers, our designer making moldflow

analysis for studying the condition of mould running. we engage in the biggest possibilities to avoid any errors or short-comings in the mould

design. so that we can solve many moulds problems in the computer before happen in the workshop.

Service:

Different customers, different cases, wecustomize for you.

customer service: in order to conformtoin ternet develop, we have advanced internet platform, so the customers cancommunicate with our engineers

online and solve your problems online.

Before-sale service:

offer hotline consulation for products and techniques. We can design moulds as your special requirements.

Mid-sale service:

offer installation, adjustment service,and practical training.

After-sales service:

24 hours repairing service. offer you 1year's guranteed for whole mould, but our service is forever.

We offer you not only a bottle crate mould,but a fine solution…

WhatsApp:008613758679372

Skype:sinomould-01

Email:export@sinomould.com

Sino Mould is one of Chinese famous brand plastic injection mold designer, maker and exporter, which established in 2000.Until now, we have more than 20 year experience in designing and making variouskinds of plastic injection mold, especially crate molds. Iam glad to share onekind of crate mold that made by us, Coca Cola crate mold.

Below are someinformation of one Coca Cola crate mold we have made :

Coca Cola Crate weight:1.3kg

Coca Cola Crate bottleNo. : 24 bottles

Coca Cola crate dimension:410*310*240mm

Coca Cola crate molddimension : 850*750*655mm

Hot runner forthis Coca Cola crate mold : 6 tips hot runner with Anole Hot Runner system

Injection moldingmachine : DKM650T servo motor molding machine

Coca Cola crate moldsteel : DIN1.2738 with Be Cube with mold guaranteed life 3 million shots

Coca Cola cratemold spare parts: OEM standard

Cycle time: from28s to 35s, it depends on the hot runner and injection machine

Ejection way:Hydraulic Cylinder with stripper plate or hook system with stripper

We are professional Coca Cola crate mold manufacturer, If you have any project of bottle crate mold, please contact me, I will offer good price for you withdetail mold information.

Post by MissMandy

Email: export@sinomould.com

Whatsapp:008615757610702

SINO MOULD has chinese high mentality packaging mould company, specialized inoffering customers high quality multi-cavities PET preform mouds, cap/ closure moulds, PET Blowing moulds andmedical parts, etc.

We use high quality steel for all packaging moulds, design with optimal molding and cooling system, during the past 10 years, SINO MOULD has provide international market with 350 sets high standard packaging moulds annually.

SINO MOULD has strong design and manufacturing capability, multi-cavity PET preform moulds with hot runner valve gate system, cap mould with unscrewing ejection way, flop top cap mould with automatic close system.

PET preform mould-valve gate system

Hot runner system elements interchangeable on the machine. Germany origin heating elements with durable heating performance. Valve gate system design for material sealing.

Mould base steel: DIN1.2311 with precision grinding machine with each plate thickness tolerance 0.015mm for plate size 500x500x40 with HRC 32.

Mould spare parts: DIN1.2344 in D-E-M metric dimension standard, all the moving areawas inserted with durable parts which is interchangeable.

Based on our know-how and years of experience and development, we are professional inoffering tailor-made solution or all your packing projects.

With professional support, we can help you become competitive in the market, and with high quality mould and prompt aftersales service, SINO HOLDINGS GROUP iseager to grow with you.

If you have any demand for PET preformmould, pls feel free to contact Miss Nancy.

WhatsApp:008613758679372

With the pace of life to speed up, now more and more people like convenience in daily life. So, the disposable plastic cutlery is becoming more and more popular in our life, it has much demand in the market, at the sametime the plastic spoon also has much demand. we are specialized in making all kinds of disposable spoon mould, forks mould, knife mould.Almost all types of cutlery moulds , we can design and make according to the customer original sample, or we can modify the design according to customer requirement. we have offered many high quality, durability spoon mould for our customers

Spoon dimension: 170X28mm

Spoon weight: 4.8g±0.1g

Spoon cavity number: 24cav

Spoon material: PP/PS

Hot runner information: 24 point hot runner

Mold dimension: 950 *550*539mm

Injection cycle time: 10-12s

Mold manufacturing time: 55-60days

Suitable machine: DKM268SV

Mould feature: support to make both PP/PS material, design according to PS material. Logo interchangeable on molds. Injection gate at design red point position.

Our company also can produce various different kind of disposable plastic cutlery.Such as plastic PS cups mould, plastic fork and knife mould, thin-wall food container mould, etc.

Welcome your enquiry for all types plastic spoon mould.

From: Stacy

Email: export@sinomould.com

What's APP: +86 15168642559

Sino Mould supply high quality plastic painting pail mould with IML molding line solution, we are experienced for different sizes painting pail mould manufacturing, such as 1L, 2L, 3L, 5L, 8L, 10L, 15L, 20L, 25L and other series painting bucket mould. welcome your enquiry.

For the painting pail mould, according to the product design, weight requirement, we could make the bucket mould with precision dimension, it could pass the water seal testing, drop testing, air tight testing and other necessary inspection requriement. Sino Mould make bucket mould supplied to all over the world, from Asia to South America, From Middle East to Europe.

Painting pail mould, with good steel material for the mould core and cavity, precision tooling, optimized cooling system, the bucket mould could run fast and smooth. We supply high quality IML bucket molding solution, with bucket mould and bucket injection molding machine manufacturing, IML robot and other auxiliaries supplying together.

Sino Mould supply painting pail mould with multi-cavity solution, we have experience for small bucket mould to big size bucket mould. Welcome to contact us for more information. Thanks.

Post by Miss Celina

Skype: sinomould.dakumar7

Whatsapp: 008615257606120

Email: export@sinomould.com

More than 20 years’ experience of injection molds making, and strong design ability, Sino could offer you high quality interchangeable crate molds, such as milk crate, banana crate, bread crate,vegetable crate, etc. Every year, we export more than 200 sets crate molds to different customers.

Sino strong design team could help you R&D interchangeable crate molds with different height, different shape (such as with hole/without hole), for example, interchangeable milk crate with different height.

For crate molds, the most important is weight control & wall thickness control, we have precise tooling machine and QC control department, which could ensure mold with high precise size, and supply high quality crate with your required weight and wall thickness.

Usually for milk crate molds, we choose 4 tip or 6 tip hot runner for more balance injection. Some factory will use recycle material production, for this point,we have our special design for manifold to improve product quality and moldlife.

Our crate molds have good cooling system which could offer you fast cycle time, we could supply milk crate molds with 30s. Before we have make thinwall crate mold with BeCu, cycle time is 15s.

Any needs for interchangeable milk crate molds, vegetable crate molds, fruit crate molds, beer crates, welcome to send your inquiry to me.

Miss.Ysaline

Skype:sino.pm

Whatsapp:+86138 5763 5311

SINOHOLDINGS GROUPE are consists of SINO MOULD CO.,LTD and Dakumar Machinery CO.Ltd. We are expertise in IML bucket molding line .

DAKUMAR is a world famous plastic injection molding machine manufacturer and an innovator in China, we are aimed at offering customerhigh speed qualified plastic injection machines, providingplastic molding technologies as well as turnkey molding solutions. DAKUMAR was established on 2007 year, we keened on 5H molding mentality of High Speed, Highprecision,High Energy Saving,High safetyand High cycle stabilityduring machines designand manufacturing.

Nowdays ,In mold labelling production line are moreand more popular in many market . there are many advantage of making in moldlabeling molding lines .So what is In Mold Labeling (IML)?

In mold labeling is a part decorating technique used worldwide for blow molded bottlesas well as injection molded and thermoformed containers or other plastic objects.Pre-decoration is the application of a label to a container before it is filled with product.

Here are some advantages of in molding label bucket production line.

Maximum output

With electric&hydraulic high-performancemachines,you will achieve maximum output at extremely short cycle times.Powerful electric and hydraulic injection units, barrier screws with a highplasticising rateenable topperformance.

Reduce operating costs

Increase your output and still save operatingcosts. And the long operational life span and low maintenance costs of SINO

help you to control your "total cost of ownership".

DAKUMAR is a good in mold labeling system supplier in China which offers stable and high speed in moldlabeling solutions with advanced IML process and technologies.welcome tocontact me for more information about your in mold label projects .

Posted by Selinda

E-mail :export@sinomould.com

Whatsapp:008615858629913

Sino offer high quality PET preform molding line. Sino Mould is a professional mould manufacturer for plastic injection mould, we could make multi-cavity cap mould and PET preform mould; Dakumar Machinery is professional machinemanufacturer for plastic injection molding machines, we could supply differenttypes plastic injection molding machines, such as PET injection molding machinewith servo motor and other engineering plastic material injection moldingmachines. Sino Mould and Dakumar Machinery are sister company both belong toSino Holdings Group, we could supply PET molding equipments with good serviceand favorable price.

For the PET preform mould, we use stainless steel material for the mould coreand cavity inserts, with valve gate hot runner system and have copper wearplate for sliders moving. All the mould plates tooling with high precisionmachines to make sure the PET preform mould could run fast and balance. We haverich experience for the multi-cavity PET preform mould, like 24cavity, 32cavity, 48cavity, 72cavity,96 cavity and so on.

For the PET preform mould, it is special designed according to the PET rawmaterial property and molding requirement:

1. Big diameter screw design and L/D ratio.

2. High plasticization capacity.

3. Extended machine framework.

4. Six stages precise temperature control for barrel.

5. Dehumidifying dryer selected for PET resin's special demands for removingmoisture; Color doser for mixing the colorant with PET material completely andprecisely. And some other additional machines like loader, chiller, aircompressor, crusher, mould dehumidifier and so on.

Posted by Selinda

E-mail :export@sinomould.com

Whatsapp:008615858629913

SINO MOULD is a lead manufacturer which is specializing in variety of plastic injection moulds, our factory is located in HUANGYAN---the mould base production base of China.

Our main products are plastic commodity molds, such as Chair mold, table mold, basketmold, crate mold, bucket mold and other plastic products. SINO MOULD will offer you not only molds, but a fine solutions.

As chinese top plastic mold manufacturer,from 2000 to 2010, SINO MOULD has invested more than 20 USD of various plasticmould tooling equipments, in july of 2005, SINO MOULD has carried out the quality managements according with TS16949, under this management standard,SINO MOULD improved the quality management system. Such like the process managements, dimension controlling, technology and skill training, quality controlling for plastic mould design and material and components of plasticmould.

Our target goal is to be your business partner and provide you complete solutions with high quality and favorable price. We can offer you in mold design, mold manufacturing, injection molding process, these can let us to be your reliablepartner. We do believe that only good quality molds with compatible prices would let you make profit in your business.

If you are also find chinese top plastic mold manufacturer, we are looking forward to your early reply. Thank you for your trust to SINO HOLDINGS GROUP.

WhatsApp:008613758679372

Skype:sinomould-01

Email:export@sinomould.com

Round table injection production factory becomes more and more popular all over the world, especially developing countries, such South America, Middle east, etc. In 2016 year, we have a customer bought 20 sets table and chair injection production line. Welcome contact me about round table and chair injection molding one-stop service.

Normally, table and chair size are not small. So all of the molds and injection machine are large size. All of the customers pay much attention to the product appearance, weight, stronger or not, etc. So when we received the table and chair project, the first time is not start product design, mold design, etc. we will start with product analysis, because we not only offer a set of injection mold or machine, but also a very fine injection molding solution.

In this way, we will help customer improve the product function and reduce the weight and budget very well. Different mold supplier will have different ideal, SINO ideal is to offer customer turnkey project solution and equipment. Deliver 5H technology and management mentality which are high speed, high quality, high energy saving, high safety, high stability for plastic injection molding industry. In addition, we are the world famous supplier for Turnkey injection molding line with service, technology solution and equipment. If you are interested in round table injection production, welcome inquiry.

Sales engineer: Candy

email: export@sinomould.com

whatsapp: +86 15858685263