As one of the biggest mold maker in China, Sino has rich experience in flip top cap mold China. We offer customer not only a good quality mold, but also a very fine injection molding solution together with complete one-stop service.

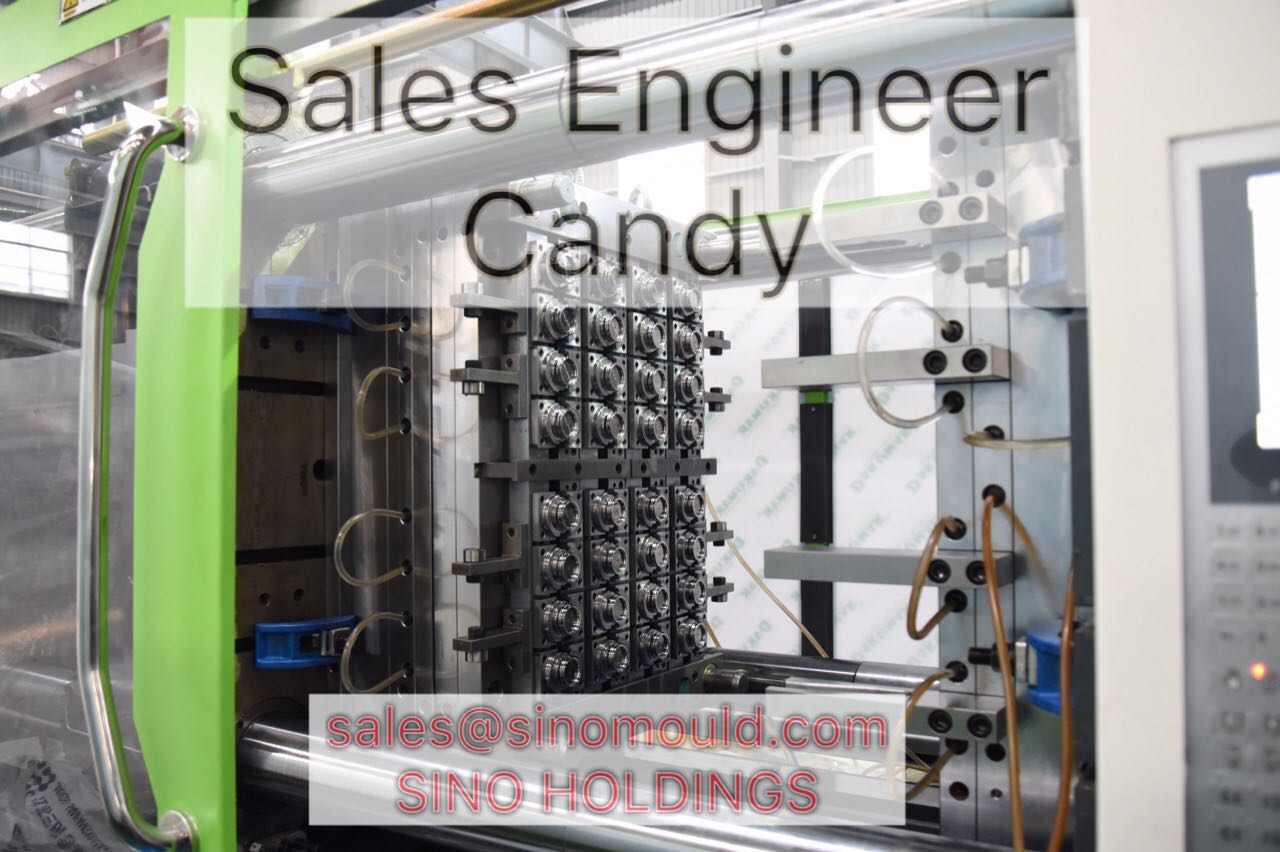

Sino flip top cap mould feature:

Mold name: flip top cap

Mold cavity: 24 cavities

Runner system: 24 points Anole hot runner

Ejection: automatic flip top close, fully automatic drop

Mold life: 2 Million

Core and cavity steel material: S136

Mold base: P20

Cylinder: hydraulic and air models

Automatic flip top cap mold structure is more difficult than normal caps, the mold ejection system is special and have double steps. the cap closing success rate is very important to the mold.

Sino is the only mold maker in China, who can make 24 cavities flip top cap mold with automatic closing system. Automatic production equipment is much more safer than human made. And it will help save cost in employee labors. Full automatic is international trend toward. If you want to improve your injection equipment, welcome contact me free. We are flip top cap mold China and looking for more and more partner all over the world.

Sales engineer: Candy

email: export@sinomould.com

skype: anole-hc-02

In order to satisfy more and more orders quantity, Sino Package company set out a series water cap injection mold maker standard parts, which helped us quicker cap mold delivery time directly.

Water cap injection mold is same to PET preform mold, they are belong to large output capacity package products. Most of the molds will have 5~10 times longer using life than normal mold. In addition, most of the caps are international standard, which included 28mm, 28PCO, 38mm, 38PCO, 48mm, 48PCO, etc.

Sino mold has our own cap mold standard process and parts:

Mold cavity and core steel: S136 (S420)

Mold base: P20

Slider and insert: DIN 1.2344

Hot runner brand: Anole hot runner

Mold guarantee life: 5 million

Delviery time: 65 days

8 hours trial production before delivery to make sure the mold action is smooth and fine the mold problem in our factory.

Process equipment:

Fidia high speed CNC machine made in Italy

Sodic EDM with high precision made in Japan

Mazack high performance lathe machine made in Japan

Sino not only offer water cap injection mold maker, but also offer customer high speed injection molding machine. Any inquiry welcome contact me freely.

Sales engineer: Candy Wang

email: export@sinomould.com

whatsapp: 0086 15858685263

skype: anole-hc-02

Sino Packing Mould Co.Ltd is one of the best Chinese PET preform mold maker,can supply you high quality multi-cavities PET mould. Sino mould devote ourselves into PET preform molding research and development for more than ten years. Annually, Sino mould making more than 600 sets of various PET Preform injection Mould and cap or closure moulds.

PET bottle molding solution preform bottle solution technology shows as below: you need:

1.recycled material is allowed to beused(this is only for using bottle. Not for water bottle or any other drinking bottles),but you can't use recycled material only .new resin material must be used with it

2.the size of the preform bottle and the caliber of the size is important. and also whether the preform bottle caliber has taper is also important.

3.specific injection machine is needed for PET preform bottle molding solution

4. valve gate hot runner system is needed for PET preform bottle molding solution. this is special hot runner system .itdoesn't use thermocouple to controller and test the temperature of each injection points. but used voltage, and also the controller box that used for PET preform bottle molding solution is also different than normal temperature controllerbox. On the other hand. This kind of PET bottle hot runner system is much cheaper than other valve gate hot runner systems.(some countries still use cold runner to inject PET preform bottles and then cut the runner).

5.different thickness and degree must controlled very well.

Written by Tina

export@sinomould.com

whatsapp:008615067608197

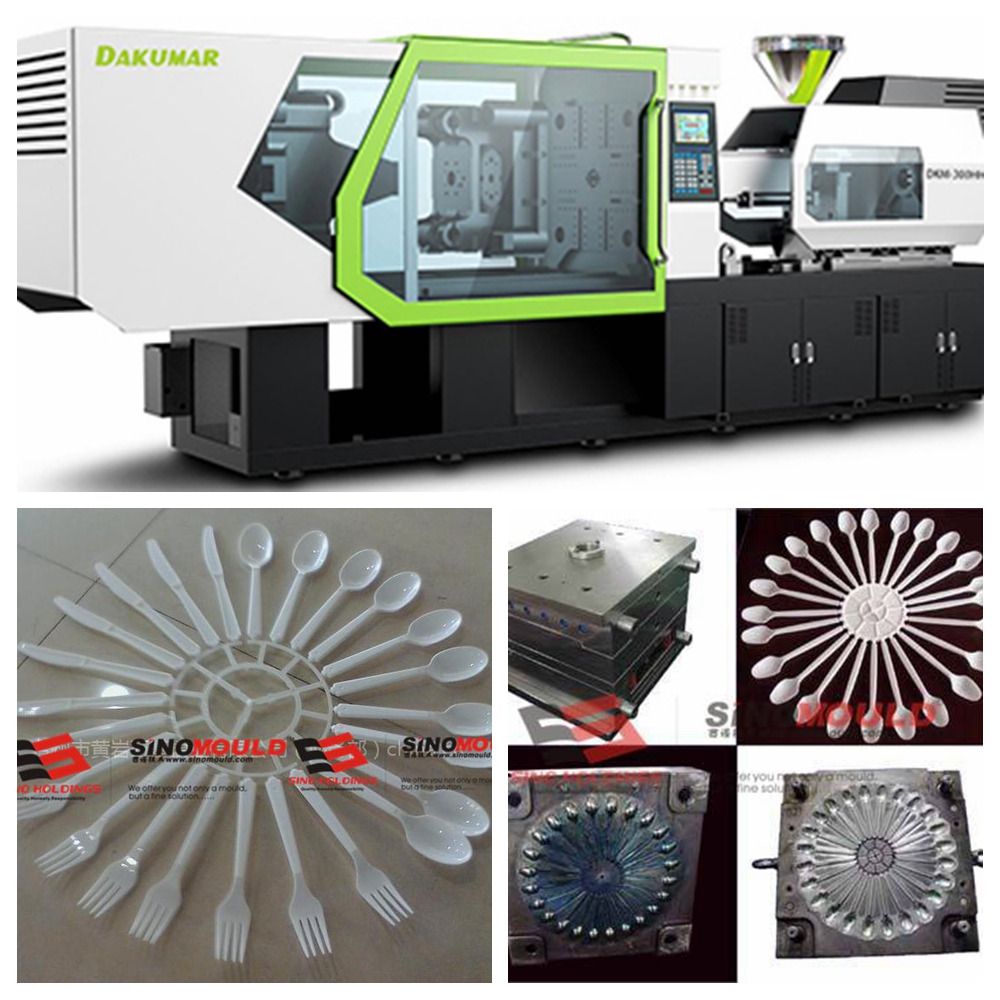

Nowadays , cutlery such as plastic knife,spoon,forks are in great demand , so more and more investor are looking fornew project to produce the plastic cutlery production line to produce bigquantity of plastic cutlery ,so more and more plastic plant are looking for goodquality of spoon mould,fork mould,knife mould .etc.

Sino mould has rich experience inoffering the cutlery mould.tableware mould manufacture in China, such asspoon mould ,knife mould, fork mould. we can make 8-48cavity tableware mouldwith smoothness verge. Excellent quality with reasonable price

Product name: 32caivty plastic spoon mould

Mould cavity:32cavity

Mould size:6200*550*500mm

Suitable machine:200T Dakumar high speedinjection molding machine .

Mould material: H13 (DIN.1.2344)

Mould life:3 Million shots

Runner system:1 tip hot runner

Mould running: Full automaticity

Injection cycle time:15 seconds

Delivery time:35days

For plastic cutlerymould ,we use H13 or DIN.1.2344 and other good steel material according tochair design and production quantity requirement. With optimized cooling systemand well-designed mould structure, Meanwhile ,the spoon mould.fork mould,knifemould partline is very important to the customers. We Use high precision milling machine for the spoon mould parting line tooling, it could save quite alot time for the mould fitting and the spoon and fork parting line is morecomfortable.

We are professional cutlery mould supplier to make spoon mould,fork mould and knife mould ,long mould lifetime and high quality and cycle time. welcome to contact us for more details .

Whatsapp:008615858629913

E-mail:export@sinomould.com

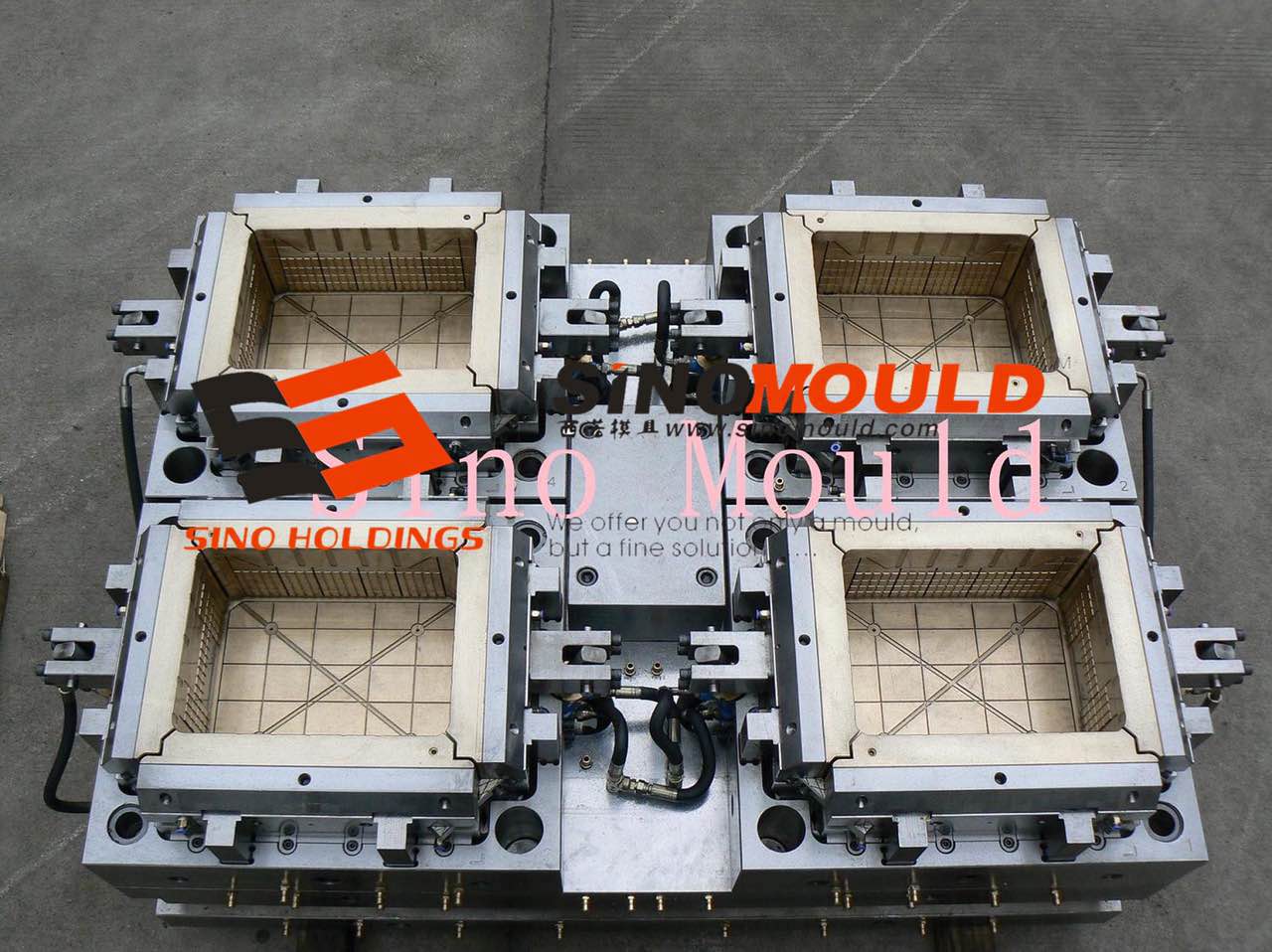

Sino Holdings Grouphave two branches company ,which is aimed at offer for plastic crate mouldmanufacturing and plastic injection molding machine manufacturing. we couldoffer fruit crate molding production line to help customer set up newcrate production plant.eight you have experience on plastic parts or withoutany experience on this plastic filed.

Sino Mould make various types plastic crate moulds,our range includes food container mould , fruit crate mould .vegetable cratemould ,bottle crate mould and so on.According to different raw material, as thecrate and container are used for transportation, most people are use HDPE toproduce the crate for mass production .With the development of injectionmolding technology, we make the crate mould and less weight.Meanwhile we aremaking make the crate injection machine for customer.too.

Sino Mould make various types plastic crate moulds,our range includes food container mould , fruit crate mould .vegetable cratemould ,bottle crate mould and so on.According to different raw material, as thecrate and container are used for transportation, most people are use HDPE toproduce the crate for mass production .With the development of injectionmolding technology, we make the crate mould and less weight.Meanwhile we aremaking make the crate injection machine for customer.too.

For plastic crate mould, we use P20, 718H, H13and other good steel material according to crate part design and mould designand production quantity requirement.we will consider perfect cooling system forthe crate mould .so every water cooling groupe our designer are design it withoptimized cooling system and well-designed mould structure, the chair moldingline could run high efficiency. Use high precision milling machine for the cratemould parting line tooling, it could save quite a lot time for the mouldfitting and the crate parting line is more comfortable.

We are professional crate production line supplier. welcome to contact us for more details .

Whatsapp:008615858629913

E-mail:export@sinomould.com

Sino mould has rich experience in crate mould manufacturing. Sino can provide customers various kinds of plastic injection moulds, especially in 4 cavities crate mould making , we can according to the product design and mold design to produce it with high quality, and can also offer special injection molding machine, robot and necessary the auxiliary equipment to help our customers achieve excellence in production capacity, at the cost of investment.

Sino 4 cavities crate moulddesign have been updated many times, it is suitable for high speed injection moulding, Servo energy saving injection machine .

Specifications of the 4 cavities crate mould :

Mould Name : 4 cavities crate mould

Product description:Fruits plastic crate

The crate size is 400*300*160mm,

Crate Mould cavity:4 cavities

Crate Mould Size:1520x1202x850mm

Suitable machine:1200TDakumar machine

Crate Mould main material:MOLDMAX Copper Beryllium+DIN 1.2311

Crate Mould life:5000K

Crate Mould Injection system:16 pointsANOLEhot nozzle with point gate.

Crate Mould Ejection system:Stripper plate

Crate Mould running:Full automaticity

Crate Mould Injection cycle time : 32 seconds

Delivery time : 90 days

moldmax in the moulding area, the injection speed can approach 32 seconds.

Crate Mould features:High classic very mature crate mould structure, The application of Copper Beryllium leads to best cooling effect, ANOLE hot runner‿professional filter system design, suitable for high speed recycled material injection production.

If you are looking for a professional mold manufacturer ,4 Cavities Crate Mould supplier ,please feel free to contact us, we won't let you down.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

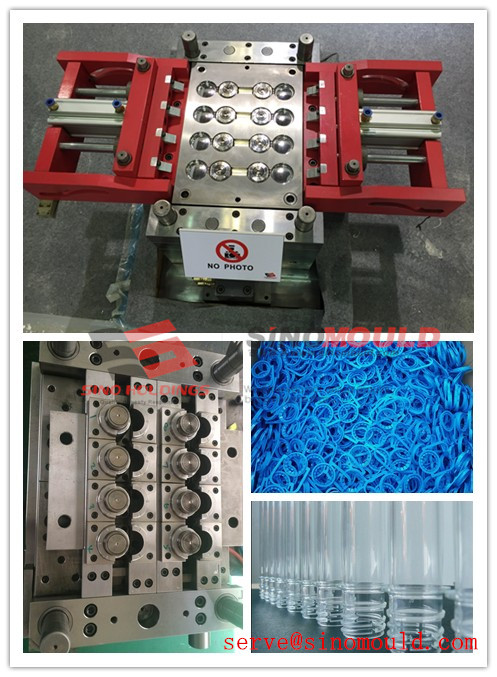

We are professional in making all kinds of cap moulds with multicavity, such as 12,24,32,48...Which is depended on customers’ requirements. Now we have a ready 32 cavity cap mould for selling which is complete new , if you are interested in , details are listed as below.

Mould Information:

Product name: PCO28 cap

Plastic: HDPE

Cavity no: 32

Injection gate: 24 tip hot runner point gate

With Germany heating elements

Mould size: 670*430*500mm

Mould base: 1.2311

Core/Cavity steel: Stavax S136, made in ASSAB

Suitable machine: DKM250SV servo motor injection machine

Technical Highlights:

1. Fast production cycle 6-8s, output 345,600pcs per day

2. Stable performance, mould life 5 million shots

3. Inserted cavity and core inserts, easy maintenance

4. Full hot runner system, with German heating elements, no material waste

5. Optimal cooling system

6. Spare parts provided, easy maintenance

7. Japanese Mazak high speed lather machine Mazak with tolerance 0.005mm

8. Japanese Sodick EDM with tolerance 0.005mm

If you are just looking for such 32 cavity cap mould,pls kindly come to me for further information.

Martina

Skype:sinomould-17

Email: export@sinomould.com

Phone/Whats APP: 0086+15215807221

Sino is a professional and world famous plastic mold manufacturer. In recent years, in the field of high-precision mold, sino also has been a major breakthrough in the industry respected,Sino Mould has a richexperience inplastic basket mould manufacturing. We had made various kinds of basket moulds, such as Plastic laundry basket mould shopping basket mould, kitchen basket moulds.

We can offer plastic basket mould solution with beryllium copper or moldmax on the core. With moldmax, the mould cooling will be much better and the cycle time will be much shorter.

According to sino’s experience, the steel material are suggested to use P20,718H, 1.2738 , It depends on the mould size and customer requirement.

For the cavity of the plastic basket mould, areoften suggest customer to make 1 cavity, 2 cavity and 4 cavity basket molds. Also , We will manufacture our moulds according to your productivity requirement.

Sino also focus on establishing a full production line for plastic basket for the customers all over the world,we can provide customers turnkey project service with both plastic basket moulds and injection machine providing. Dakumar injection machine is one of the members of Sino Holdings Group,and its our own machine brand too.

When you got the moulds and machine from Sino , you can start production immediately .You don’t need to negotiate with different supplier for moulds and machine. Also you don’t need to worry about after sales service problem. We will be responsible for aftersales service for both moulds and machine.

If you are searching for a experienced plastic basket mould supplier, and interested in Sino. Please feel free to contact me .we won't let you down.

Posted by: Rose Wang

E-mail:export@sinomould.com

Whatsapp/tel:+8613738591683

Skype: Sino mould-Rose

Backed by an experience of almost two decades, SINO are a reputed manufacturer and supplier of plastic spoon mould. We offer mould like disposable Spoons, Plastic Disposable Spoon, Durable PlasticSpoons, Disposable Plastic Spoons, Hygienic Plastic Spoons, Designer Plastic Spoon, Plastic Forks, Plastic Knifes, Ice-creams Spoons, Ice-Creams SpoonMoulds, Soup Spoon Moulds and Fruit Fork Spoon Moulds. These products have highquality,flexibility, mechanical properties and durability. Manufactured usinghigrade raw material, these products find wide application in variouscommercial and domestic sectors. The products that we offer are tested on setquality parameters.

Spoon dimension: 170X28mm

Spoon weight: 4.8g±0.1g

Spoon cavity number: 24cav

Spoon material: PP/PS

Hot runner information: 24 point hot runner

Mold dimension: 950 *550*539mm

Injection cycle time: 10-12s

Mold manufacturing time: 55-60 days

Suitable machine: DKM268SV

Mould feature: support to make both PP/PSmaterial, design according to PS material. Logo interchangeable on molds.Injection gate at design red point positions.

SINO not only provide injection mould forcustomers from all over the world, but also injection machine, auxiliaries machine and all the necessary equipment necessary to built a perfect plant se tup.

Anyinterests for plastic spoon mould, welcomesend your inquiry to me!

Skype:sinogroupe-62

Email: export@sinomould.com

SINO MOULD specialize in the plastic packing molds manufacture.Especially for the plastic water cap mold, preform mold, test tube mold etc handle molds. SINO MOULD company pay much attention on the market investment and research. To match more and more customer market demand, We invest several sets of packing molds to satisfy customer urgently demand and shortest delivery time. Below are the molds detail information, if you are interested, please do not hesitate to ask us and get the most favorable price.

Preform Mold:

Product size: PCO28

Mould size: 550*350*490mm

Weight: 13g

Cycle time: 16s

Cavity:8

Injection gate: Anole valve gate system

Water Cap Mold:

Product size: PCO28

Mould size 1 : 1.4g 24 cavity for550*430*460mm

Mould size 2 : 2.2g 32 cavity for670*430*500mm

Cycle time: 12-15s

Injection gate: Anole point gate system

Flip Top Lid Mold:

Product size: 48mm neck size

Mould size: 600*400*525mm (auto-closure flip top cap)

Weight: 8.4g

Cycle time: 18-22s

Cavity:8

Injection gate: Anole point gate system

28mm Handle Mold:

Product size: PCO28

3 Plate mold size: 590*530*405mm

Weight: 2.5g

Cycle time: 15s

Cavity:16

Sino mould always do our best to serve customer and support our best molds quality and service. And we are knee to offering fast delivery ready molds to meet customer daily urgent demand. Thank you so much support our service and hope you would prefer our this service.Looking forward to hearing from you any idea and comments.

Post by Tina

Contact mail:export@sinomould.com

whatsapp:008615067608197

SINO HOLDINGS GROUPE are aimed at offering IML bucket production line.either for experienced customer or new start plant. We can offer in mold label bucket moulds, bucket molding machine ,and necessary auxiliary. we have rich experience in offer to IML bucket container and in mould bucket production line.

Why now the IML bucket and container ismore and more popular in the market and in many factories? There are manyadvantages.

1.new and beautiful appearance.

As the in-mold labels and plastic parts naturally blend together, with the deformation of the blow bucket deformation, so there will be no bubble, wrinkles and so on.

2. environmental protection.

Ordinary labels are to be labeled after the container is molded, and the in-mold labels and containers are finished once, thus preventing contamination of the bottle by the labeling process. Moreover, the in-mold label and the bottle body are completely integrated chemical composition of the same, can be recovered together, and the recycling rate is high.

4. easy to fall off and damage

The In-mold label with waterproof, anti-oil, mildew, Naisuan Jian, friction and other properties, the special state is not easy to damage.

5. The side walls are reinforced.The label is embedded in the side wall of the plastic container so that the extrusion resistance of the container side wall is increased by 20% so that the label does not undergo separation when the container is warped and squeezed.

6. High efficiency and high efficiency.

We are professional in making the in mold label container and IML bucket .including in mold label injection mould. injection molding machine and in mold label robot system .we have delviery more than 702 turnkey production line .

Welcome to contact us for more information.

Whatspp:008615858629913

E-mail:export@sinomould.com

HuangyanSINO HOLDINGS GROUP has developed a professional and comprehensive management system for plastic injection molds, we use the leading Proe, UG, moldflow

Plastic Injection mould for Hanger

Placeof origin: Huangyan China

Description:plastic injection mold for cloth

Cavity:2, 4,6,8,12

Brandname: SINO MOULD

Plasticmaterial: PP

MouldSteel: P20

Runner:Hot runner

Wehave rich experiences in making hanger mould, we export more than 1200 setsmoulds to the world market, 150 sets moulds is Hanger mould.

SINOMould Quality

MachiningCMM& other dimension controlling.

SINOQC team devote ourselves in processing QC control:

Wepay more attention in design and analysis QC control, our designers andengineers spend more effort in the mold design analysis process. For some newlydeveloped projects of customers, designers making moldflow analysis forstudying the condition of mold running. So the quality control of mold designhas been more rigorous. We engage in the biggest possibilities to avoid anyerrors or short comings in the mold design. So that we can solve many mouldsproblems in the computer before happen in the workshop. We set up mature QCcontrol system, which starts from the very beginning of each

project.

If you are alsointerested in Plastic Injection mouldfor Hanger, pls feel free to contact Miss Nancy.

Email:export@sinomould.com

Skype:sinomould-01

WhatsApp:008613758679372