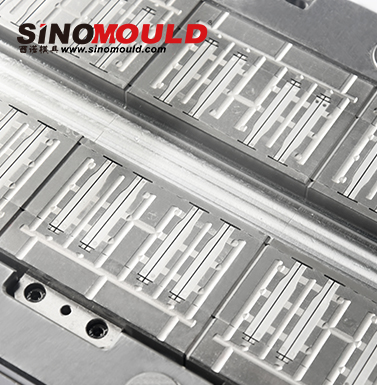

SinoMould medical mould Depart., with 20 years of accumulation of medical syringe mould technology, has invented a 64 cavities high-efficiency syringe mould with full hot runner system, which is the good choice for high-standard syringe manufacturers in the world. Combined with DKM medical specialized injection molding machine, SinoMould can provide turnkey project of integrated syringe production line.

SinoMould medical mould Depart., with 20 years of accumulation of medical syringe mould technology, has invented a 64 cavities high-efficiency syringe mould with full hot runner system, which is the good choice for high-standard syringe manufacturers in the world. Combined with DKM medical specialized injection molding machine, SinoMould can provide turnkey project of integrated syringe production line.

| Product Name | Syringe Mould |

|---|---|

| Plastic Material | Syringe Barrel: PP

Syringe Plunger: PP Syringe Gasket: TPE or TPU |

| Product Volume | 1ML, 5ML, 10ML, 20ML to 25ML |

| Mould Cavity | Syringe Barrel: 16-64 Cavity

Syringe Plunger: 6-48 Cavity Syringe Gasket: 144 Cavity Reachable |

| Cavity & Core Steel | S136 |

| Mold Base Steel | 4CR13 Pre-Hardness |

| Cavity & Core Hardness | Pre-Hardness Steel: HRC 33~36

Heat Treatment Steel: HRC 50~52 |

| Mould Accessories | Compatible to DME/HASCO Standard. |

| Mould Life | 500,000 Shots Mould Life or 1 Year Quality Guarantee under Normal Use |

| Hot Runner | Point Gate Hot Runner |

| Delivery time | 35 Days after Prepayment |

| Packing | Standard Fumigated Wooden Cases |