Plastic Injection Molding

SinoMould plastic injection molding is a one-stop injection molding service provider, service from the plastic 3D modeling, components molding analysis, mold design and manufacturing to the plastic parts' surface treatment. SinoMould uses intelligent plastic injection molding management mode and scientific injection molding technology, combined with advanced injection molding equipment, to provide customers with efficiency and high-quality injection molding solution.

If you need plastic injection molding or mould making service, please leave your contact infomation

If you have detail information need to contact us directly,please click the button below

contact us

In order to help you estimate your designed plastic components' cost, SinoMould developed an automatic plastic molding quotation system, it appears very accurate and smart calculation. You can get your plastic parts quoted by filling some basic & simple information. Please click to try this magic system!

At SinoMould, we specialize in providing high-quality plastic injection molding services to customers in a wide range of industries. Whether you need a small run of prototype parts or large-scale production of complex components, our experienced team can deliver the results you need.

Our injection molding capabilities include a wide range of materials, including commodity and engineering resins, as well as custom blends and colors. We use advanced injection molding machines and technology to produce parts with precise tolerances and exceptional quality.

At SinoMould, we are committed to providing the highest level of service and quality to our customers. We have a team of experienced professionals who are dedicated to ensuring that every project is a success. Whether you need help with design, prototyping, production, or secondary operations, we have the expertise and technology to deliver the results you need.

Plastic Injection Molding Process-SinoMould Provide

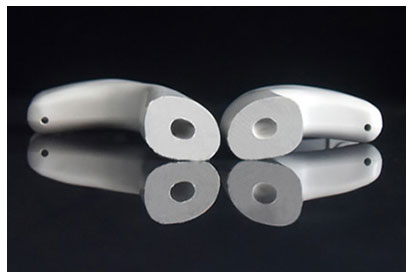

Medical injection molding (clean injection molding)

Plastic injection molding can produce a wide variety of plastic parts, ranging from small, intricate components to large, complex structures. This process can be used to produce parts for a range of industries, including automotive,medical, consumer goods, and more.

Gas-assisted injection molding

Gas-assisted injection molding is a variant of plastic injection molding that involves the use of high-pressure gas to create hollow or partially hollow plastic parts. This process is used to produce parts with thicker wall sections and complex geometries that are difficult or impossible to achieve with traditional injection molding techniques.

Large Plastic Parts Injection molding

Large plastic parts and engineering plastic parts injection molding is used to produce plastic parts that are larger in size and have more complex geometries. Producing large plastic parts through injection molding requires specialized equipment, including large-tonnage injection molding machines(4000Ton,6000Ton)and molds that can accommodate the size and complexity of the parts being produced.

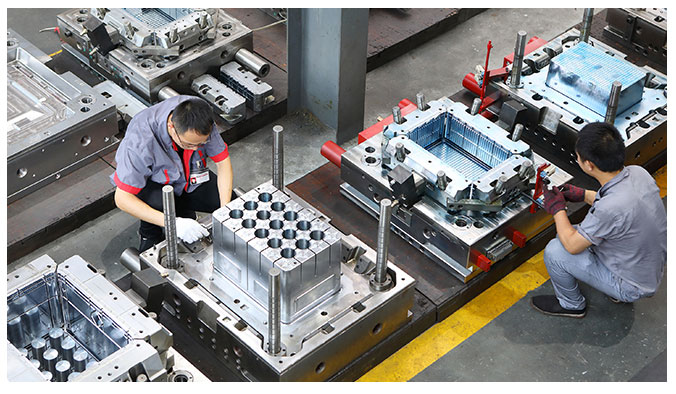

Injection Molding Equipment SinoMould Equipped

SinoMould specializes in the design and manufacturing of high-quality plastic injection molds for a wide range of industries, including automotive, medical, and consumer electronics. The company has invested heavily in advanced technology and equipment to ensure that it provides the best possible products to its customers.

Some of the advanced technologies and equipment used by SinoMould for injection molding are:

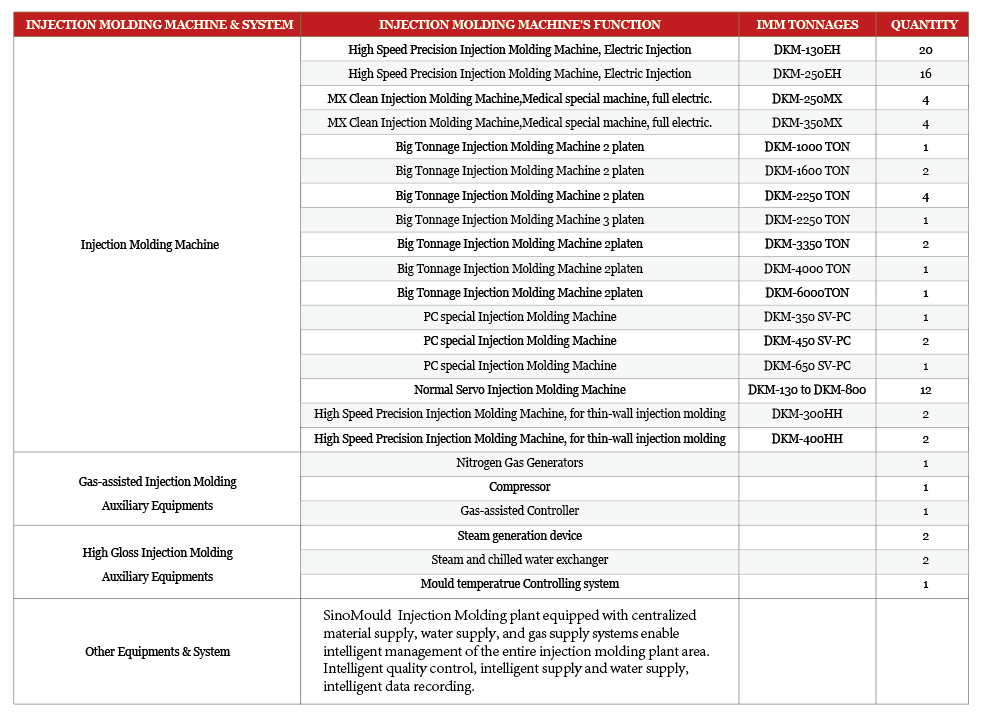

| INJECTION MOLDING MACHINE & SYSTEM |

INJECTION MOLDING MACHINE'S FUNCTION |

IMM TONNAGES |

QUANTITY |

| Injection Molding Machine |

High Speed Precision Injection Molding Machine, Electric Injection

|

DKM-130EH

|

20 |

| High Speed Precision Injection Molding Machine, Electric Injection |

DKM-250EH |

16 |

| MX Clean Injection Molding Machine,Medical special machine, full electric. |

DKM-250MX |

4 |

| MX Clean Injection Molding Machine,Medical special machine, full electric. |

DKM-350MX |

4 |

| Big Tonnage Injection Molding Machine 2 platen |

DKM-1000 TON |

1 |

| Big Tonnage Injection Molding Machine 2 platen |

DKM-1600 TON |

2 |

| Big Tonnage Injection Molding Machine 2 platen |

DKM-2250 TON |

4 |

| Big Tonnage Injection Molding Machine 3 platen |

DKM-2250 TON |

1 |

| Big Tonnage Injection Molding Machine 2platen |

DKM-3350 TON |

2 |

| Big Tonnage Injection Molding Machine 2platen |

DKM-4000 TON |

1 |

| Big Tonnage Injection Molding Machine 2platen |

DKM-6000TON |

1 |

| PC special Injection Molding Machine |

DKM-350 SV-PC |

1 |

| PC special Injection Molding Machine |

DKM-450 SV-PC |

2 |

| PC special Injection Molding Machine |

DKM-650 SV-PC |

1 |

| Normal Servo Injection Molding Machine |

DKM-130 to DKM-800 |

12 |

| High Speed Precision Injection Molding Machine, for thin-wall injection molding |

DKM-300HH |

2 |

| High Speed Precision Injection Molding Machine, for thin-wall injection molding |

DKM-400HH |

2 |

| Gas-assisted Injection Molding Auxiliary Equipments |

Nitrogen Gas Generators |

|

1 |

| Compressor |

|

1 |

| Gas-assisted Controller |

|

1 |

| High Gloss Injection Molding Auxiliary Equipments |

Steam generation device |

|

2 |

| Steam and chilled water exchanger |

|

2 |

| Mould temperatrue Controlling system |

|

1 |

| Other Equipments & System |

SinoMould Injection Molding plant equipped with centralized material supply, water supply, and gas supply systems enable intelligent management of the entire injection molding plant area. Intelligent quality control, intelligent supply and water supply, intelligent data recording.

|

|

|

Advantages of Sino Injection Molding Service

At SinoMould, we specialize in providing high-quality plastic injection molding services to meet the diverse needs of our customers. With our strong injection mold manufacturing ability, complete injection molding equipment, and strict process control, we are committed to delivering reliable, consistent, and cost-effective solutions that exceed your expectations.

Our injection molding services cover a wide range of industries and applications, including automotive, consumer electronics, medical devices, household appliances, and more. Whether you need to produce small or large parts, complex or simple geometries, or high-precision or high-volume runs, we have the expertise and resources to meet your needs.

Powerful Plastic Injection Mold Manufacturing Ability

One of our key strengths is our plastic injection mold manufacturing ability. We have a team of experienced and skilled engineers and technicians who use the latest design software and equipment to create high-quality injection molds that meet your specifications.

Strict Plastic Injection Molding Process Control

At every stage of the injection molding process, we adhere to strict quality control standards to ensure that your products meet your exact specifications. We use advanced testing and inspection equipment to monitor and verify the quality of your parts, and we can provide detailed quality reports upon request.

At SinoMould, we are committed to providing the highest quality plastic injection molding services and solutions to our customers. Contact us today to learn more about how we can help you with your injection molding needs.

Customization and Flexibility

SinoMould offers a range of customization options for plastic parts, including material selection, part design, and finishing. They can also handle small or large volume orders and provide fast turnaround times.

Quality and Consistency

SinoMould is committed to delivering high-quality plastic parts that meet or exceed customer expectations. They have a rigorous quality control process and use advanced inspection tools to ensure consistency and accuracy.

Customer Support and Service

SinoMould has a team of dedicated professionals who are available to provide support and assistance throughout the entire injection molding process, from design to delivery. They also provide ongoing technical support and maintenance services to ensure the continued success of your project.

Introduction of Sino Auto Quotation System

Sino Auto Quotation System is an innovative and automated system that can streamline your cost estimation process for your plastic injection molding projects. With this system, you can get an immediate and accurate quote for your project by filling out a simple form that contains all the information about your product.

With Sino Auto Quotation System, you can easily upload your products dimensions, specify your material requirements, select your desired finishing options, and provide any other specifications required for your project. The system will then automatically generate a quote based on your input, providing you with an accurate and competitive cost estimate.

The benefits of Sino Auto Quotation System are numerous. First and foremost, it saves time. Traditional manual cost estimation methods can take hours, if not days, to complete. With Sino Auto Quotation System, you can receive an immediate quote, giving you more time to focus on other aspects of your project.

In addition to saving time, Sino Auto Quotation System also increases accuracy. By using automated algorithms, our system ensures that your quote is as accurate as possible, reducing the risk of errors or miscommunications. This level of accuracy also allows for more effective budgeting and planning for your project.

Another advantage of Sino Auto Quotation System is its convenience. Our system is easy to use, and you can access it from anywhere, at any time. All you need is an internet connection and your product specifications, and you can receive a quote within minutes.

Sino Auto Quotation System also provides a high degree of customization. You can select from a wide range of materials, finishes, quantities, and other parameters to ensure that your quote is tailored to your specific project requirements. Our system is flexible and can accommodate even the most complex projects.

Overall, Sino Auto Quotation System is a game-changer for plastic injection molding cost estimation. It streamlines the process, increases accuracy, and provides a high degree of customization, all while saving you time and money.

If you're looking for plastic injection molding service, just try out auto quotation system and get immediate quotation.

Plastic injection Molding Technology

Plastic Injection Molding by SinoMould

Plastic Injection Molding FAQ

1.What is the hardest plastic for injection molding?

The hardness of a plastic used for injection molding depends on several factors such as its chemical composition, molecular weight, and crystallinity. Generally, engineering-grade thermoplastics are considered to be the hardest plastics for injection molding due to their high stiffness, strength, and resistance to heat, chemicals, and impact.

Some of the hardest plastics commonly used in injection molding include:

Polycarbonate (PC):

PC is a tough and durable thermoplastic that offers excellent impact resistance and high strength. It is commonly used in applications such as safety helmets, automotive parts, and electronic components.

Acetal (POM):

POM is a highly crystalline thermoplastic that offers excellent stiffness, toughness, and dimensional stability. It is commonly used in applications such as gears, bearings, and electrical components.

Polyphenylene Oxide (PPO):

PPO is a high-performance thermoplastic that offers excellent dimensional stability, high strength, and resistance to heat and chemicals. It is commonly used in applications such as automotive parts, electrical components, and consumer goods.

Polyphenylene Sulfide (PPS):

PPS is a high-performance thermoplastic that offers excellent chemical resistance, high strength, and dimensional stability. It is commonly used in applications such as automotive parts, electrical components, and industrial machinery.

Polyetheretherketone (PEEK):

PEEK is a high-performance thermoplastic that offers excellent strength, stiffness, and resistance to heat and chemicals. It is commonly used in applications such as aerospace, medical devices, and oil and gas equipment.

It's important to note that the hardness of plastic is just one of the many factors to consider when selecting a material for injection molding. Other important factors to consider include the specific properties required for the application, the processing conditions, and the cost of the material.

2.What are the major factors affecting a Plastic Injection Molding Process?

The major factors affecting a plastic injection molding process are:

Temperature:

The temperature of the molten plastic and the mold can affect the flow and cooling of the plastic.

Pressure:

The pressure of the molten plastic during injection and the holding pressure during cooling can affect the part quality.

Injection speed:

The speed at which the plastic is injected into the mold affects the filling of the mold and the quality of the part.

Cooling time:

The time it takes for the plastic to solidify in the mold affects the cycle time and part quality.

Mold design:

The design of the mold affects the filling, cooling, and ejection of the part.

Material selection:

The choice of plastic material affects the properties of the part and the processing parameters.

Machine performance:

The performance of the injection molding machine, including the clamping force, shot size, and screw speed, can affect the process and part quality.

3.What are the three main sequences of operations in the injection molding of a plastic part?

The three main sequences of operations in the injection molding of a plastic part are:

Injection:

The first sequence involves melting the plastic material and injecting it into the mold cavity. The plastic is heated to a molten state and then injected under pressure into the mold cavity through the sprue and runner system.

Cooling:

The second sequence involves cooling the plastic part until it solidifies and can be ejected from the mold. The cooling time depends on the thickness and geometry of the part, as well as the material being used.

Ejection:

The third sequence involves removing the plastic part from the mold. The mold opens and the part is ejected by pins or ejector plates. The mold is then closed again and the process is repeated for the next cycle.

4.How do you choose plastic material for Plastic Injection Molding?

Choosing the right plastic material for plastic injection molding requires careful consideration of various factors, including the part design, required properties, and processing requirements. Here are some steps to help you choose the right plastic material for injection molding:

Determine the application requirements:

Identify the specific properties required for the part, such as strength, stiffness, impact resistance, chemical resistance, and temperature resistance.

Consider the part design:

Consider the geometry and wall thickness of the part, as well as any features such as ribs, bosses, or threads. This will help you select a material that can fill the mold and provide the required structural integrity.

Evaluate processing requirements:

Consider the processing conditions required for the material, such as the injection molding machine, temperature, pressure, and cooling time.

Compare different materials:

Once you have identified the application requirements, part design, and processing requirements, compare different plastic materials that meet those requirements. Consider factors such as cost, availability, and environmental considerations.

Test and validate the material:

Once you have selected a material, test and validate it through prototyping and testing to ensure it meets the required specifications and performance criteria.

Some common plastic materials used in injection molding include polypropylene, ABS, polycarbonate, nylon, acetal, and PEEK. It's important to work with a reputable material supplier and injection molding manufacturer to ensure the material is suitable for the application and can be processed effectively.

5.What are the five common problems with injection molding of plastic parts?

Injection molding of plastic parts can sometimes lead to various defects or problems that affect the quality of the final product. Here are five common problems that can occur during injection molding:

Warping:

Warping occurs when the plastic part cools and shrinks unevenly, causing it to bend or deform. This can be caused by improper cooling, uneven wall thickness, or insufficient draft angles.

Sink marks:

Sink marks occur when the plastic part cools and shrinks, causing depressions or dimples on the surface. This can be caused by thick sections in the part, improper gate design, or insufficient packing pressure.

Flash:

Flash occurs when excess plastic material leaks out of the mold, causing thin fins or protrusions around the part. This can be caused by excessive injection pressure, worn or damaged mold components, or improper clamping force.

Short shot:

A short shot occurs when the mold cavity is not filled with plastic material, resulting in incomplete or missing features. This can be caused by insufficient injection pressure, insufficient resin in the barrel, or a blocked gate or runner.

Voids:

Voids are empty spaces or bubbles within the plastic part, which can weaken the structure and affect the aesthetics. This can be caused by trapped air or gas, excessive moisture in the resin, or improper venting of the mold.

6.What kind of plastic is used in injection molding?

Plastic injection molding is a widely used manufacturing process for producing plastic parts in large quantities. There are a variety of plastics that can be used in injection molding, and the choice of plastic depends on the specific requirements of the application. Some common types of plastics used in injection molding include:

Polypropylene (PP):

PP is a versatile thermoplastic that is widely used in injection molding due to its excellent chemical resistance, low cost, and good mechanical properties. It is commonly used in the production of automotive parts, packaging, and consumer goods.

Acrylonitrile Butadiene Styrene (ABS):

ABS is a tough, rigid thermoplastic that is widely used in injection molding due to its excellent impact resistance, dimensional stability, and ease of processing. It is commonly used in the production of automotive parts, toys, and electronic enclosures.

7.Why Choose SinoMould for Plastic Injection Molding?

At SinoMould, we understand that choosing the right plastic injection molding service is crucial to the success of your project. With so many options available in the market, it can be difficult to determine which service provider is the best fit for your needs. Here are 5 compelling reasons why you should choose our plastic injection molding service:

Experience and Expertise

We have been in the plastic injection molding business for many years and have accumulated extensive experience and expertise in the field. Our team of professionals has a deep understanding of the various processes involved in plastic injection molding, and we have the latest technology and equipment to provide high-quality and efficient services.

Quality Assurance

At SinoMould, quality is our top priority. We use only the highest quality materials and employ rigorous quality control measures throughout the entire process, from design to delivery. Our state-of-the-art inspection equipment ensures that every part we produce meets the highest standards of quality and precision.

Competitive Pricing

We offer competitive pricing for our plastic injection molding services without compromising on quality. Our transparent pricing structure ensures that you receive a fair and accurate quote for your project, and we strive to work within your budget while still delivering top-notch results.

Customization and Flexibility

Every project is unique, and we understand that customization and flexibility are essential to meet our clients' needs. We offer a wide range of customization options, including material selection, finishes, colors, and more, to ensure that your project is tailored to your specific requirements.

Exceptional Customer Service

At SinoMould, we pride ourselves on delivering exceptional customer service. We work closely with our clients to understand their needs and provide personalized solutions that meet their specific requirements. Our team is always available to answer questions, provide updates, and offer support throughout the entire process.

In conclusion, SinoMould is the ideal choice for your plastic injection molding needs. With our experience, expertise, quality assurance, competitive pricing, customization and flexibility, and exceptional customer service, we are committed to delivering outstanding results that exceed your expectations. Contact us today to learn more about our services and how we can help you bring your plastic injection molding project to life.

8.What is the Scope of SinoMould Injection Molding Services?

At SinoMould, we pride ourselves on providing a comprehensive plastic injection molding service that meets the diverse needs of our clients. Whether you need a prototype or a high-volume production run, we have the expertise and resources to deliver the results you need. Here are some of the products we can make and the injection molding processes we specialize in:

Products We Can Make

We offer a wide range of products that we can manufacture using plastic injection molding. Some of the products we make include:

Consumer products, such as kitchenware, toys, and electronics

Automotive parts, such as dashboards, door panels, and interior trims

Medical devices, such as diagnostic equipment and surgical tools

Industrial parts, such as machine components and housings

Packaging, such as caps, closures, and containers

Injection Molding Processes We Specialize In

At SinoMould, we specialize in a variety of injection molding processes to ensure that we can meet our clients' unique needs. Some of the injection molding processes we offer include:

Medical Injection Molding:

This process is to inject molten plastic into medical injection mold and cool to get required medical equipment and consumables.

Gas-Assisted Injection Molding:

This process involves injecting nitrogen gas into the molten plastic to hollow out thick sections of a part, which reduces material usage and shortens cycle time.

High Gloss Injection Molding (RHCM Injection Molding):

This process uses a unique process that involves rapidly heating the mold cavity just before the plastic is injected. The rapid heat causes the plastic to melt quickly and uniformly, reducing the time required for the plastic to flow and fill the cavity.

INS Injection Molding (including IMD or IML injection molding):

This process involves applying a decorative or labeling film to a mold surface and injecting molten plastic around the film, creating a finished part with the decoration or label already applied.

Injection Molding of Large Plastic Parts, Injection Molding of Engineering Plastic Parts:

This process is used to produce plastic parts that are larger in size and have more complex geometries. Producing large plastic parts through injection molding requires specialized equipment, including large-tonnage injection molding machines and molds that can accommodate the size and complexity of the parts being produced.

In conclusion, at SinoMould, we offer a comprehensive plastic injection molding service that includes a wide range of products and processes to meet the diverse needs of our clients. We pride ourselves on providing high-quality results, competitive pricing, and exceptional customer service. Contact us today to learn more about our services and how we can help bring your project to life.

9.How Can I Get Plastic Injection Molding Quotation from SinoMould?

Getting a plastic injection molding quotation from SinoMould is easy and convenient. We offer two ways for customers to get a quote: by contacting our sales engineers directly, or by using our auto quotation system on our website.

Method 1: Contacting Our Sales Engineers

If you prefer to discuss your project with one of our sales engineers, simply navigate to our website and find the

"Contact Us" page. From there, you can fill out a form with your contact information and a brief description of your project.

One of our sales engineers will contact you shortly to discuss your project in more detail and provide you with a customized quote based on your specific needs. Our experienced engineers have extensive knowledge of plastic injection molding and can help you determine the best materials, processes, and design options for your project.

Method 2: Using Our Auto Quotation System

For customers who prefer a more immediate quote, we offer an automated quotation system on our website. Fill out the form with your project details, including the part dimension, material, quantity, and any additional requirements and get immediate plastic injection molding quotation.

Our auto quotation system will provide you with an instant quote based on your inputs. This quote is generated using advanced algorithms that take into account the most up-to-date pricing and production information, ensuring that you receive a highly accurate quote for your project.

Advantages of Using Our Auto Quotation System

Our auto quotation system offers several advantages over traditional quoting methods:

Speed: You can receive an instant quote for your project, saving you time and allowing you to move forward with your project more quickly.

Accuracy: Our system uses advanced algorithms to generate highly accurate quotes, ensuring that you have a clear understanding of the costs involved in your project.

Convenience: You can access our auto quotation system at any time, from anywhere in the world, making it easy and convenient to get a quote for your project.

Overall, our plastic injection molding quotation process is designed to be simple, convenient, and accurate, providing you with the information you need to make informed decisions about your project. Whether you prefer to speak with one of our sales engineers or use our auto quotation system, we are committed to providing you with the highest level of service and quality.

Conclusion

Plastic injection molding are an essential tool for many industries, from automotive to medical. They allow us to produce parts quickly and accurately, with the ability to customize the parts according to our needs. With the advancements in technology, injection molding machines are becoming more efficient and easier to use. This allows us to produce higher quality products at a faster rate than ever before. In conclusion, injection molding machines are a valuable asset for any industry that needs precision parts in large quantities.

Overall, SinoMould may be a suitable option for businesses looking for a reliable and efficient partner for their plastic injection molding needs.