What Plastics are used in Injection Molding?

A wide variety of plastic materials can be used in injection molding, including:

advantages of plastic injection molding:

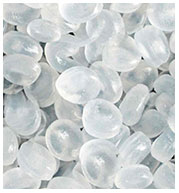

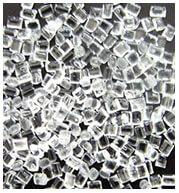

Acrylonitrile Butadiene Styrene (ABS):

A thermoplastic polymer that is known for its toughness, impact resistance, and heat resistance.

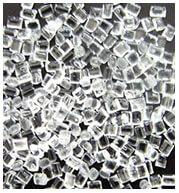

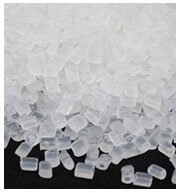

Polycarbonate (PC):

A thermoplastic polymer that is known for its high strength, transparency, and heat resistance.

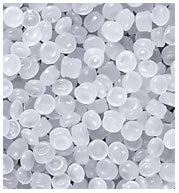

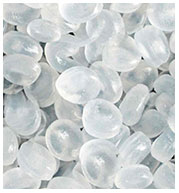

Polypropylene (PP):

A thermoplastic polymer that is known for its stiffness, chemical resistance, and heat resistance.

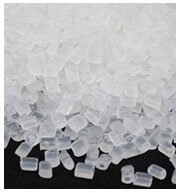

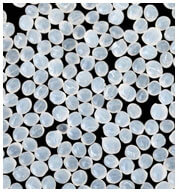

Polyethylene (PE):

A thermoplastic polymer that is known for its flexibility, low density, and chemical resistance.

Polyamide (PA):

A thermoplastic polymer that is known for its strength, stiffness, and heat resistance.

Polystyrene (PS):

A thermoplastic polymer that is known for its low cost, transparency, and ease of processing.

Polyethylene terephthalate (PET):

A thermoplastic polymer that is known for its transparency, strength, and durability.

Polyurethane (PU):

A thermoset polymer that is known for its toughness, flexibility, and abrasion resistance.

Polyphenylene oxide (PPO):

A thermoplastic polymer that is known for its high heat resistance, strength, and dimensional stability.

ABS

PC

PP

PE

PA

PS

PET

PU

PPO