Chinese New Year Holiday Period -2012

Chinese new year holiday 2011 will start from Jan. 21 2012 to Feb. 2nd 2012. During this period of time all the Chinese companies will stop their office working and most of the goverment office also closed.

Sino Holdings Group started the Chinese New Year Holiday From Jan. 22nd 2012 to Feb. 1st of 2012, during this period of time, we can not send you the quotation and other email answer on time. But all the quotation and detailed information will be feedback to you before 2nd of Feb. Sorry for the disconvenience.

Wtih our best wishes to you and your family.

Very best regards,

Sino Holdings Group

a.A good mould design.

b.Precise machining, reasonable machining process and dimension controlling.

How to manufacture a good plastic injection molding machine?

a.Good machine design. (machine function is fixed by its deisgn)

How to explain high performance plastic injection mold?

High performance plastic molds has below features:

For thin wall injection mold, which steel should we choose, H13, DIN 1. 2344,Stavax S420.

Which one is the best? Why?

1.All the mentioned steel is available.

If we need a plastic part which the thinkness is only 0.45mm, this plastic part need mirro polished completely, please tell us if the plastic shrinakge is 1.5%,then after milling and before polishing, we assembled the core and cavity, how much the distance should be between the core and cavity?

1.The distance between core and cavity should be 0.45 * 1.015mm this distance is after the final polishing.

High technologies for plastic parts manufacturing, Plastic Parts Supplies, Plastic Parts Molding, Plastic Parts Customizing, Plastic Parts Manufacturing, Chinese Plastic Parts Molding, Plastic Parts Molding China, Plastic Parts Customizing China and Plastic Parts Supplies in China.

Sino Molding Company is the professional plastic parts molding companies in China, offer you the plastic parts customizing, from the plastic parts 3D design to molds making, injection molding, plastic parts assembling, plastic parts surface treatments and packaging.

Sino Molding Company Onestop plastic parts molding service has became the famous plastic molding suppliers in the world, we equiped with high precision injection molding equipments and devices with the dust-free workshop and rigorous quality and efficiency managements.

We offer you the qualified plastic parts manufacturing service with enconomical costs and on time delivery.

--Post by:Charlene

Skype:sino.group03

Email:export@sinomould.com

export@sinomould.com

For plastic product ejection to occur,the injection mold must open the shape of the molded plastic product determines whether it can be ejected simply by opening the two mold halves or whether undercuts must be present.

The design of a injection mold is dictated primarily by the shape of the plastic productto be molded and the provisions necessary for product ejection.Injection-molded products can be classified as:

1. Products without undercuts(e.g.,plaques,strips,half-shells,cups).

2. Products with external undercuts or lateral openings

(e.g.,spools and bobbins,beverage crates, threaded bolts).

3. Products with internal undercuts(e.g.,threaded closures,housings).

4. Products with external and internal undercuts

(e.g., bumper fascias,electrical and antomotive instrument housing,cameras).

Post by: Charlene

Skype:sino.group03

MSN:export@sinomould.com

Mail: export@sinomould.com

export@sinomould.com

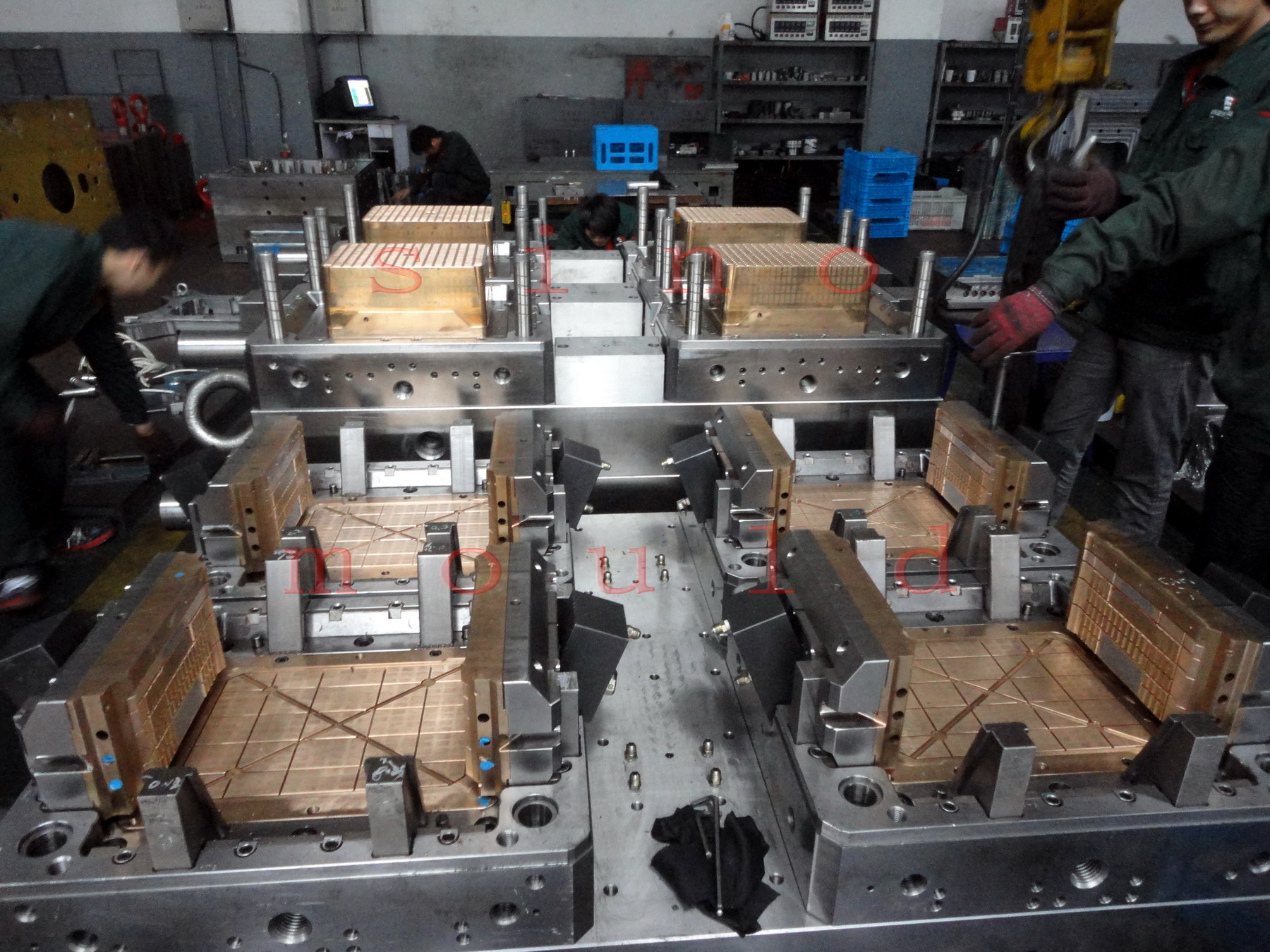

The crate also called logistics box, widely used in machinery, automobiles, home appliances, light industry, electronic industry. Crate production with the reasonable design, excellent quality, apply to factory in logistics transportation, distribution, storage, circulation processing and other links.

Therefore the demand of crate becomes more and more. Crate production has higher and higher requirements for the efficiency and high quality. So the multicavity mould is popular with more and more mass crate production suppler.

export@sinomould.com

Single ply roofing system molds made by Sino Mould (www.sinomould.com, export@sinomould.com , were succeeded finished and delivered to our clients.

single ply roofing system molds are becoming more and more popular in roofing system industry, in the past several years we have made roofing system molds for our America, European, middle-east Asian clients, in fact the roofing system molds are not difficult, normally the roofing system parts is only 1 meters square. So the roofing system molds is middle size.

Single ply roofing system molds injected with PU foam, or PU foam + PE plastic material, sometimes clients use PU foam + PVC to make injection, the results is not good, because the flowing of PVC material is not good. finally they changed PU+ PE to make injection, the part looks good.

How to choose a plastic factory site? If you want to build a new plastic factory, the plastic factory site selection is very important. How to choose plastic factory site? The following information should be helpful: