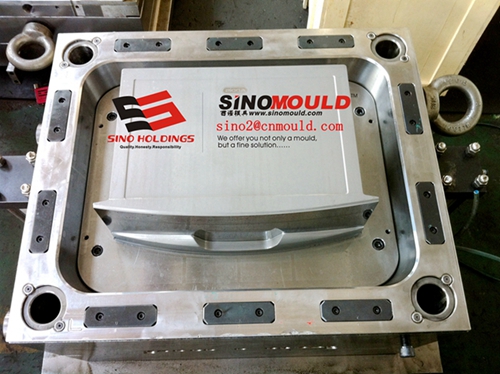

Ourcompany is expertized in making plastic daily drawer system molds in china, weaims to offer good drawer set molds with superior part fittings. For different daily drawer system molds, we haveexported to south Africa, Indonesia, brazil, and so on.

Mold name:wide drawer system molds

Moldcore/cavity steel:718H steel for this mold, but we can make according to your request, like P20,DIN2738 and so on.

Mold hot runner:Anole brand valve gate system, with heating element from Germany.

Mold features:sino standard mold base, mold is designed with D-M-E metric dimensions for moreconvenient future mold maintenance. Also mold is supported to make drawer basewith labeling. For good drawer appearance, this set drawer system molds aremade with fine textures on surface.

For daily drawer system molds, wesupport to make parts as light weight but good strength. Each part fitting areais we pay high attentions. Only with these areas of good machine tooling canmake sure final good parts assembling. We also offer two hours mass productionsimulation process running at sino to show you mold quality before shipping. Ifyou need daily drawer system molds, pls feel free to contact with us.

MsDiana

Mail:export@sinomould.com

Skype:sino.group01

Whatsapp:0086 13757677056

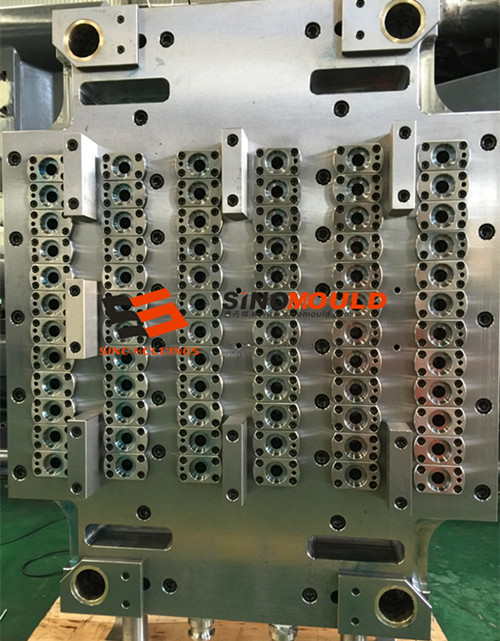

It's popular to start to make medical plastic parts among people looking for great business related health, one is syringe.And luer lock syringe injection mould by SINO is respected among partners.If you are looking for a supplier for quality mould of kinds ofsyringe: 1 ml, 3 ml,5 ml,10 ml,20 ml,30 ml,60 ml, etc,then it will be glad that the blog can do something to you.

What is the most considered when you looking for a medical mould for luer slip syringes? It could be high precision,easy maintenance and mass production capacity and satisfactory service, then is the price generally. Thus I list something for your reference, hope it could be helpful for you.

How to ensure the quality of final syringe? Anyway, the plastic product made finally good or not decides the business success or fail. That's, quality syringe is the key for the whole project to you!

·product analysis

At the beginning, the primary product design will be made according to the product analysis by professional team, which could be improved as excellent experience and technological analysis. Such as angle of product, material suggestion, product structure details, making the welding line unapparent.

·mould design

Suitable mould structure bases on the final syringe that it should be, then according the innovative design, which could enhance the efficiency of molding. Not only for cooling system to shorten thecycle time, but the structure for reliable function of product. Such as the polishing range should be mirror one, interchangeable inserts, and the steel of major mould.

·mould tooling control

Controlling details in mould parts tooling can achieve the perfect design to be fact. Thus regarding the way of manufacturing, sometimes it seems ok, but in a while, not in the long runner. That's why the top equipment arises and being owned by manufacturers to strengthen the competitiveness( which enhance yours as well in some ways).

In short, any questions, kindly leave your comments here. Of course welcome to mail me for more info.

Lucy is always here and sincerely invites you to become a solid partner of SINO to develop better together!

export@sinomould.com

WhatsApp: +8615757605003 (online servicefor you)

With more than 20 years plastic injection molds manufacturing experience,sinomould is professional in plastic mold industry in china. we are full capabilityof supplying different injection molds for our customers, such as electricalbox accessories molds making.

As for electricalbox accessories molds, usually it has like electrical wire box mold, wallplates molds, electrical cover molds, electrical socket molds and so on. For thesetypes of injection molds, one of important is to make sure good fittings witheach other, especially for the area need fitting with screws.

For moldmaking, we have different choices on mold steel, P20, 718H, s136 steel and soon. Like for wall plate molds which need good shinny and mirror polishing, itis better to use S136 steel for polishing lasting. as these molds usually arenot big size, on mold tooling, we prefer to use high precision tooling for machining,and also with inspection after tooling for dimension controlling. With thisstep, usually our electrical box accessories molds are one time successfultesting for good samples, no future hand works on that.

If youhave some similar electrical box molds need to open, pls feel free to contactwith us.

Ms Diana

Mail: export@sinomould.com

Skype:sino.group01

Whatsapp:0086 13757677056

SINO HOLDINGS GROUP is a well known plasticmoulding line supplier. We supply different kinds of injection mould lineequipment. One of the popular moulding line is household production line.

Because of household product update speedvery fast, the household plastic mould, household injection moulding machine are always in demand. SINO HOLDINGS GROUP can offer various kinds of householdmolding line equipment to the plastic manufacturer. The equipment we can supplyinclude plastic mold customized, injection machine develop, and suitableauxiliary machines select. We focuses on responsible plastic houseware mouldand machine high quality. The stable machine running is the insurance of ourcustomer profit. We own excellent designers who can help customer crate goodappearance in-house plastic parts design. SINO brother company DakumarMachinery gains good reputation in injection machine field. Our talent engineersare professional in mould, injection machine, auxiliary equipments and know howto operation them in best condition, how to maintain the equipment, they alsocan teach customers’ engineers. We keen on help you solve all difficulties in thehousehold product molding line. Welcome to contact SINO MOULD sales engineerMs. Summer. We offer diamond service.

Email: export@sinomould.com

Skype: sino-mould02

Web: www.cnmould.com

www.dakumar.com

Sino mould was established in 2000 year, we have more than 20 years chair moulds production experience. We make all kinds of plastic chair molds, which included babies safety car seat molds, arm chair mould, baby high chair injection molds. And we have exported babies’safety chair molds to some European countries before.

Baby safety chair mould always means total set molds. Because the chair combined with cushion, chair leg and other small parts. These molds look very simple, but they have higher requirements than normal chairs. The users are babies, so all of the parts can’t turn up flash or any sharp points.

All of the parts assembling should be very good to make sure the strength of the safety chair. It requires the product size and mouldsize are very accurate. About the spare parts assembling, we made adequate preparation in advance, just in the molds design, we will make analysis of the seat details when received the babies safety car seat and examine the assembling of all parts reasonable. We will point the problem and send customer a very fine solution.

Sino company’s aim is to offer our customer a fine injection molding solution. If you have require about babies safety car seat molds, welcome contact me freely.

Contact: Candy

whatsapp: +86-15858685263

email: export@sinomould.com

skype: anole-hc-02

SINO pipe fitting cooperation as SINO Holdings Branch Company is famous for the good quality and responsibility attitude to each mold. We are China famous brand for customized pipe fitting molds design and manufacture.

As we all know, normally the pipe fitting molds apply cold runner for the material strict temperature requirement. The runner diameter is bigger than other product. So what’s kind’scold runner you choose for different type pipe fitting? Compared the tunnelgate and edge gate / big gate, you will find their own characteristics and help you choose the suitable gate.

1.They areall cold runners and will have waste material.

2.The tunnelgate can auto separate and the product surface is good.

While as this gate is small that the cycle time will long, the product may short molding, the holding pressure needs tronger, there will have material marks around the gate area (injection pressure is too high)

3.About theedge gate, the dimension is larger and short cycle time.

This gate needs to be cut by men hand or robot cutting equipments increase the production cost. And there will have gate marks on pipe fitting surface.

From above characteristics, we always adopt edge gate or big gate for product diameter over than 100mm. Otherwise, we adopt tunnel gate.

Warmly welcome your contact for not only pipe fitting molds, also other plastic product injection molds.

Posted by Ms. Helen

Skype: sino.groupe10

Email: export@sinomould.com

Whatsapp/ Wechat: 0086 15858625783

The BMC(SMC,DMC) molding have 4 kinds,1st Injection Molding, 2nd compression moulding,3rd Injection Compression Molding, 4th Transfer molding, they are apply to different products respectively. their equipments including Charging system, Heating system ,Clamping equipment.

In Sino Mould you will know more about moulds technical.

In here you will know more about beneficial invest.

Sino Mould is a leading mould exporter in China. As a professional mould exporter, Sino enjoys a good reputation in world mould market. During past 20 years, Sino Mould has made all kinds ofplastic injection mould and accumulated a lot of experience in mould making and mould exporting. Annually, we exported about 1500 sets of mould to all over the world. Our moulds are noted all over the world because of good quality and competitive price.

As an experienced mould exporter in China, Sino Mould can make many kinds of plastic injection mould. We are especially strong at PET perform mould, Pipe fitting mould, crate mouldand thin wall container mould,etc..

Sino, an excellent mould maker in China, has a strong design team. There are three 3D mould design department, one product design department and one 2D design department. Our advanced machine are imported from Italy, Japan, etc.

Looking for mould maker/mould exporter? ContactSino Mould.

Miss Cina

E-mail: export@sinomould.com

Skype: sinomould-13

MSN: export@sinomould.com

If you want to start business in PET prefrommanufacturing and you are green hand to injection molding field, you shouldfind a professional supplier who is specialized in offer a turn-key PET moldingline equipment.

Pet preform moulds made by SINO MOULD is aworld reference. With high precision mold quality and long moulds life, SINOMOULD becomes the world famous PET prefrom mould maker. SINO keens on preformmolding technology research and develop. What’s more, SINO GROUP has thestrength of supply complete injection moulding line for PET preform. It’sbranch company Dakumar Machinery specialized in offer high speed and highenergy saving PET injection moulding machine. With the good knowledge of PETmoulds and PET moulding machine, our engineers can help customer customize asolution to their new plastic business. We supply fine solution from design,mould tooling, mould shipment to after sales service. We good at supply 72 cavityPET preform mold with 650 ton Dakumar injection moulding machine and auxiliarymachines. For 32 cavity 20g PET preform mould, we recommend 330ton PET machine.Also the mould core and neck sliders can be interchangeable to producedifferent kinds weight. For any of PET preform moulding line questions, you canfeel free to discuss with me.

Email: export@sinomould.com

Skype: sino-mould02

Some steel material is very common in mold process. Different plastic material should choose different steel.

Firstly, we should choose stainless steel suitable for what kind of plastic?

S136, 2316, belong to stainless steel. This kind of steel feature is good polish, good rustproof, good corrosion resistance, and excellent machinability.

This stainless steel suitable for PVC, PP, PC, PMMA, PE and so on plastic.

2344. 2343.2311.2738 this material feature is good polish, good wear, dimensionally stable, good processing performance.

This steel suit produce ejector pin, mold core and so on. The suitable plastic is PA, POM, PS, and PE.

P20, SC45 this steel is suit to produce big mould like chair this mold. Sometime we use this steel to mould base.

Edited by: Ophelia

Sales Engineer

Email: export@sinomould.com

Sino Mould Co., Lts is the plastic injection mould maker the most quickly in China, we are the short time delivery mould maker China. During injection mould production, we will speed up and give priority to urgent projects, urgent plastic injection mould of our customers, in order to reduce the mould production time and delivery time, to reduce cost for customers.