SINO MOULD is the professional plastic injection molding expert in China. As the world famous injection mould company, we are very specialized in design runner switch mould, has very rich runner switch mould manufacturing experience.

SINO MOULD knows well about how to set mould runner switch to control the production. Setting mould runner switch is more common in some multi-cavities mould, customer sometimes would like to put two different products in one mould to reduce the cost. But they usually find that the two parts needed production quantity is rather different. Maybe one product they need 10,000 sets per day, another just need 5,000 sets. In order to meet one product production, customer has to produce the two items together. It is very economical for customer.

As for the request of customers, SINO start the runner switch mould researching. Through one year researching and development, SINO has achieved significant success.

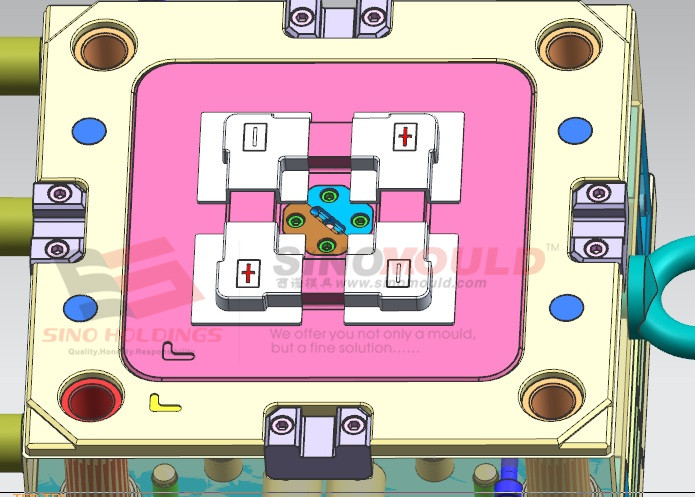

Below is the fundamental of how to set the mould runner switch.

Take this mould for an example, four cavities, we should make two runners insert like the blue and brown part. Now the picture shows the mould could just inject two parts with minus mark.

Welcome to contact me to know more about runner switch mould.

Jessie

export@sinomould.com

professional injection mould supplier China, plastic injection molding expert, plastic injection molding service, best injection mould supplier in China, world famous injection mould company

In the past, we know that oil paint is filled in the metal bucket, which is expensive and of complex tooling process. In recent few years, people tend to use plastic paint bucket.

Comparing with metal bucket, plastic paint bucket may have below disadvantage:

Bad sealing effect

Low strength

Low Recycle usage rate

SINO is a Chinese mould company which has more than 20 years plastic injection mould export experience.We are keeping offer customer marketable daily use injection mould to help customer to win the market.

Making plastic injection mould over 20 years, SINO knows very well about the world plastic market and undstand what the customer need more. So far, SINO has many its speciality mould product, such as plastic crate mold, chair mold, pipe fitting mould, thinwall container mold, packing mold, bumper mold and various daily use injection mould etc.

For different market, customer has different standard requirements for the daily use injection mould. SINO could meet all the different requiremets and design the most marketable daily use injection mould for you. Below is several simple show of our sample showroom.

DME standard is one of the mold making stand, there are 3 famous mold making stand( DME, HASCO, MISUMI) in mold industry all over the world, DME standard issued from America D-M E company, which established in 1942, with 70 years history till now. their main business is supplying mold standard accessories and hot runner system, now DME company becomes the largest mold accessories supplier, and the high quality hot runner solutions supplier. Their products sales to more than 70 countries, they offer global service.

In 2004, Sino Mould established SINO MOULD quality standard, based on DME plastic mould standard, combined with European mold requirements. SINO PLASTIC MOULD DESIGN STANDARD and SINO PLASTIC MOULD MANUFACTURING STANDARD issued in 2004.

Sino Mould professional sieve molds maker china, specializing in manufacturing sieve molds, including fruit basket sieve molds, plastic basket sieve molds, dish shelf sieve molds, rice sieve molds, etc. Professional custom sieve molds in china, becoming chinese top ten custom molding manufacturer. Do you interest in sieve molds? Looking for good sieve molds maker? Sino plastic sieve molding china, sieve molds maker, custom sieve molds, offers you best sieve molding solution.

Lucia

Skype: sinogroup-11

Email: export@sinomould.com / export@sinomould.com

Huangyanwell known all over the world by famous mould industry, Huangyan is one of three districs of Taizhou city, Taizhou , consists of Huangyan distric, Luqiao district, Jiaojiang district.

78% mold manufactures located in Huangyan district

70% of China export mould comes from Huangyan

63.2% Huangyan population work in mould industry,

58.2% Huangyan industry GPD comes from mould industry

70% China E-bike plastic parts come from Huangyan

Sino Holdings group (www.sinogroupe.com)

Sino mould co.ltd (www.sinomould.com)

Zhejiang Taoshi mould group

Zhejiang Saihao industry

Xingtai mould industry

SINO MOULD is the various mould maker in china ,which is famous in the home and abroad. The household mould we have rich experience and the exquisite technology our staff own. There is no doubt that we can offer you the best quality and long life mould ,we are the guarantee of the top mould.

We can design many types of household mould on computer, which means we can offer custom the mould according to your demand. Our household mould with good polishing on the core and cavity, by the way, we choose the top mould steel for you as we have the responsibility to do the business, during many shots, avoiding the deformation of the mould steel and the household product cannot form smoothly which will easy touch the skin. We all know the need you wish to get, so we have the ability to offer you the best quality household mould.

Mould Base: SINO STANDARD MOULD BASE

Cavity: Single/multi

Runner: Annole Hot/cold

Mould Design: 3D/2D Drawing

Design Days: 3 days

Design Software: UG, PROE, CAD, CAE, CAM, CAXA ect

Plastic Material: PP, PC, PS, PE, PU, PVC, ABS, PMMA ect

Injection System: Pin-point-gate

Polish System: Mirror Polish

Delivery Time: 60days

If you are interested in household mould and also want to find a reliable mould supplier, you can definitely contact me .

Are you interested in plastic bottle carrier molds? Still looking for bottle carriermolds maker? Sino professional custom bottle carrier molds maker, specializing in bottle carrier molding, offering you bottle carriermolds solution. No matter bottle carrier molds for beer, sports drink or for juice, coca cola or other carrier molds, Sino always provides you best. If you have any question of custom molds, feel free to contact with me.

Lucia

Skype: sinogroup-11

Email: export@sinomould.com / export@sinomould.com

At present, the FRP molding method commonly uses hand layup injection molding process, injection molding process, mould pressing craft, moulding material molding process, fiber winding injection molding process, volumes of injection molding process, bag forming process, resin casting and the injection molding process, RTM injection molding process, pultrusion molding process, the plate and pipe continuous injection molding process, enhance injection moulding technology, reaction elastomer lay aside fat moulding process, as well as plastic pick and connection technology, sandwich structure production technology, etc

Do you want to buy baby-use plastic product mould?

Then first you first find the right company which can provide you the best quality baby goods moulds.SINO MOULD is China top ten baby product mould manufacturing company which have so many experience in plastic baby-use moulds making.

We take baby health into consideration and the moulds we make is of best quality with competitive price.

Just come to SINO MOULD,and you’ll find it your ideal plastic baby commodity moulds manufacturer!

Contact:Miss Grace

Email:export@sinomould.com

Skype: sino-mould01

MSN:export@sinomould.com

Before you start plastic products invest but you cannot sure whether your product have good market,In this time, that you can make prototype mold for this plastic products, there have two way to get plastic products fast, one is prototype mold,need around 20-30days, another way is Plastic rapid prototype but without mold.

As for Plastic rapid prototype,CNC machining is the process by which material is removed from a work piece with Computer Numerical Control (CNC) equipment that cuts away unwanted material. These parts use in various kinds material of metals and plastics, for example: ABS, PP, PC, PMMA (Acrylic), PA (Nylon) Aluminum, copper, steel,etc.