We understand that outstanding mold quality stems from every detail in design, machining, and assembly. Through over two decades of dedicated research, SINO MOULD has established a comprehensive end-to-end quality assurance system underpinned by cutting-edge technology and robust processes, ensuring product competitiveness from the outset.

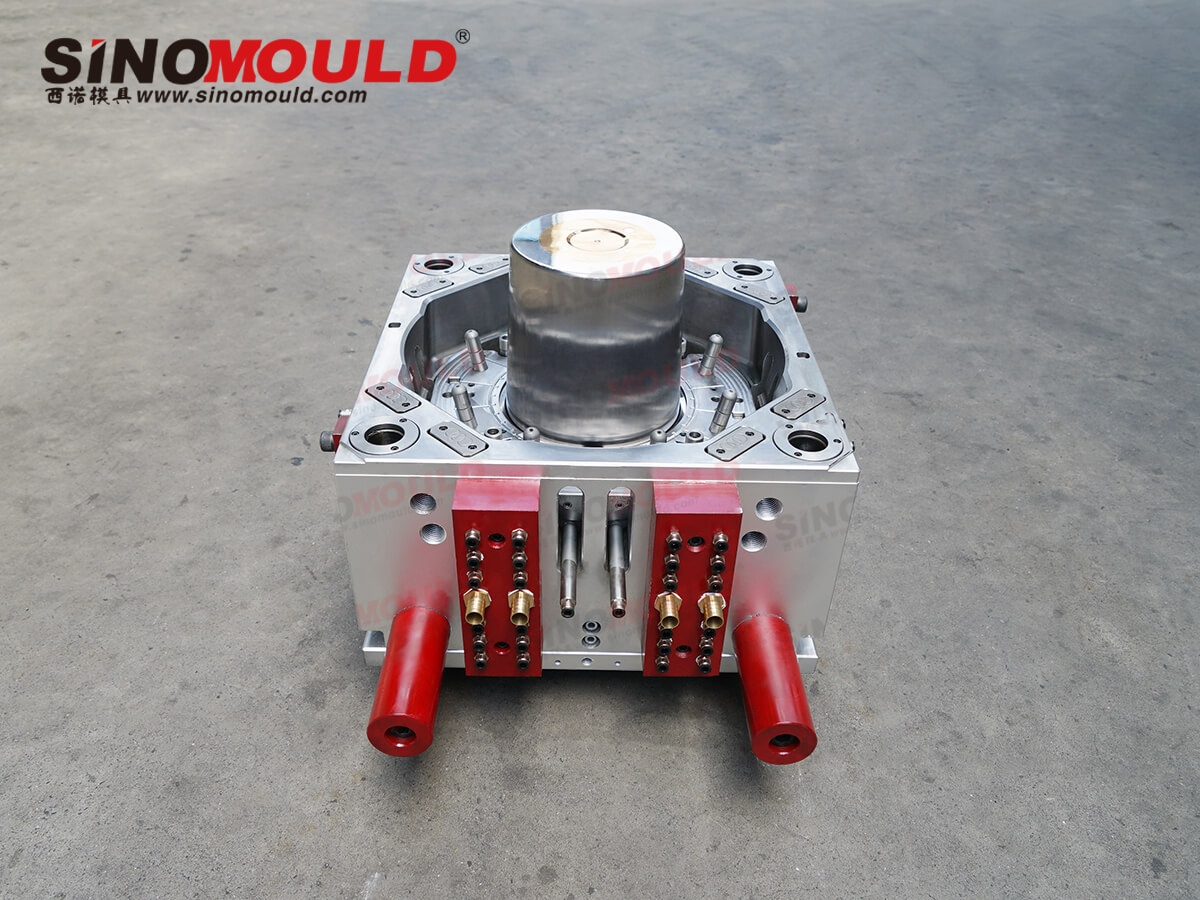

Equipped with an independently developed ejection mechanism, sliders and ejector blocks collaborate to achieve synchronous demolding of undercut structures, addressing the pain point of low efficiency in traditional demolding.

Beryllium copper material is embedded in the core/cavity inserts, combined with umbrella-shaped cooling water channels and independent cooling chambers for sliders. The molding cycle is shortened to 35-38 seconds with enhanced stability.

An independent clamping system prevents flash. High-quality 718H steel ensures mold hardness and wear resistance, with a service life of over 500,000 cycles.

Our medical-grade hot runner system, developed through deep understanding of meterial flow characteristics, achieves balanced symmetrical melt filling. This effectively resolves the mold eccentricity issues in such thin-wall components, ensuring uniform syringe barrel and plunger wall thickness. This lays a solid foundation for exceptional concentricity and dimensionall consistency in the final product.

Cumulatively delivered over 1,000 sets of molds domestically and overseas, covering multiple capacities (5L-20L), shapes (round/square/oval), and adapting to industries such as coatings and chemical engineering.

Complies with German DME and MTS quality standards, strictly controlling details from design to testing, with a rejection rate far below the industry average.

Minimizes product weight while ensuring load-bearing and drop performance, reducing customers' raw material costs.

Equipped with cutting-edge facilities like five-axis high-speed machining centers and slow-wire precision EDM, we preform micron-level machining on core mold components. This ensures seamless integration between the patented hot runner system and cavities, precisely translating design blueprints into premium products.

Supports multi-cavity mold customization, provides integrated IML (In-Mold Labeling) solutions, and is compatible with injection molding machines of brands such as DKM.

55-65 day manufacturing cycle for standard molds, immediate delivery available for some models, and 14-day rapid response to customized needs.

Offers end-to-end services from mold commissioning to operation and maintenance, boasting an industry-leading customer repurchase rate.